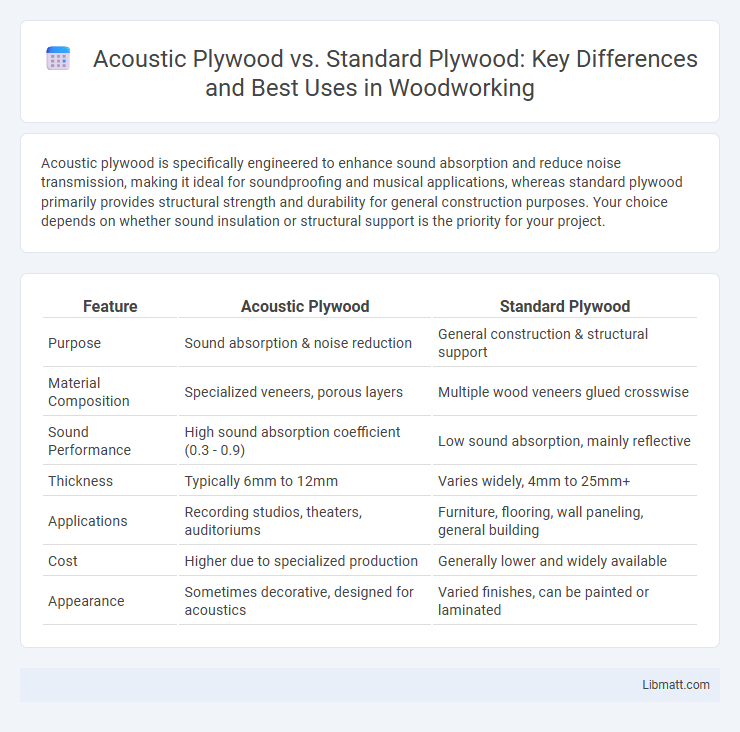

Acoustic plywood is specifically engineered to enhance sound absorption and reduce noise transmission, making it ideal for soundproofing and musical applications, whereas standard plywood primarily provides structural strength and durability for general construction purposes. Your choice depends on whether sound insulation or structural support is the priority for your project.

Table of Comparison

| Feature | Acoustic Plywood | Standard Plywood |

|---|---|---|

| Purpose | Sound absorption & noise reduction | General construction & structural support |

| Material Composition | Specialized veneers, porous layers | Multiple wood veneers glued crosswise |

| Sound Performance | High sound absorption coefficient (0.3 - 0.9) | Low sound absorption, mainly reflective |

| Thickness | Typically 6mm to 12mm | Varies widely, 4mm to 25mm+ |

| Applications | Recording studios, theaters, auditoriums | Furniture, flooring, wall paneling, general building |

| Cost | Higher due to specialized production | Generally lower and widely available |

| Appearance | Sometimes decorative, designed for acoustics | Varied finishes, can be painted or laminated |

Introduction to Acoustic Plywood vs Standard Plywood

Acoustic plywood is engineered to reduce sound transmission and improve acoustic performance, making it ideal for theaters, recording studios, and soundproofing projects. Standard plywood is primarily designed for structural strength and general-purpose construction without specific sound insulation properties. Your choice between acoustic and standard plywood depends on whether sound control or structural stability is the primary requirement in your project.

Key Differences Between Acoustic and Standard Plywood

Acoustic plywood features a multilayer structure with viscoelastic adhesives designed to absorb and dampen sound vibrations, enhancing noise reduction in applications like studios and auditoriums. Standard plywood consists of glued wood veneers primarily aimed at structural strength and durability without specific soundproofing properties. The key difference lies in acoustic plywood's superior sound insulation performance achieved through specialized materials and construction techniques, making it ideal for environments where noise control is critical.

Composition and Material Structure

Acoustic plywood features layers of wood veneer combined with specialized damping materials or porous cores designed to enhance sound absorption and reduce noise transmission, whereas standard plywood consists of uniformly glued wood veneers without soundproofing properties. The material structure of acoustic plywood often includes a composite of softwood or hardwood veneers interlaid with materials such as fiberglass or foam to improve acoustic performance. Standard plywood's layered construction prioritizes strength and stability, using cross-laminated hardwood or softwood veneers for general structural applications.

Sound Absorption Properties

Acoustic plywood is specifically engineered with enhanced sound absorption properties, featuring a porous surface and denser core layers that reduce sound transmission and echo more effectively than standard plywood. Standard plywood, while structurally strong, lacks the specialized composition needed to minimize noise, making it less effective for acoustic insulation in walls, ceilings, or flooring. Choosing acoustic plywood can significantly improve your space's sound quality by minimizing reverberation and external noise intrusion.

Common Applications and Uses

Acoustic plywood is primarily used in soundproofing and acoustic paneling for studios, theaters, and auditoriums, where enhanced sound absorption and noise reduction are critical. Standard plywood finds widespread application in construction, furniture making, and cabinetry due to its structural strength and versatility. While standard plywood serves general building and finishing needs, acoustic plywood specifically targets environments requiring improved acoustic performance.

Installation Methods Compared

Acoustic plywood installation requires precise sealing and staggered joints to maximize sound insulation, while standard plywood typically involves straightforward nailing or screwing for structural support. You must apply soundproofing adhesives or resilient channels with acoustic plywood to enhance noise reduction, which is not necessary for standard plywood. The complexity of acoustic plywood installation demands more time and expertise to ensure maximum acoustic performance.

Durability and Lifespan

Acoustic plywood features enhanced durability due to its specialized layers designed to absorb sound and resist moisture, extending its lifespan compared to standard plywood. Standard plywood, while sturdy, typically lacks the moisture and sound-resistant treatments found in acoustic variants, making it more susceptible to warping and degradation over time. Investing in acoustic plywood ensures long-term performance in environments where both durability and sound insulation are critical.

Cost Analysis: Acoustic vs Standard Plywood

Acoustic plywood typically costs 20-30% more than standard plywood due to its specialized materials and manufacturing processes designed for sound attenuation. While standard plywood ranges from $25 to $40 per sheet, acoustic plywood prices often fall between $35 and $55 per sheet, reflecting enhanced acoustic properties. The higher initial investment in acoustic plywood may be offset by reduced soundproofing expenses in construction and renovation projects.

Environmental Impact and Sustainability

Acoustic plywood is often manufactured using eco-friendly adhesives and sustainably sourced timber, reducing its environmental footprint compared to standard plywood, which may use synthetic glues and less regulated wood sources. The production of acoustic plywood aims to balance sound absorption properties with greener practices, making it a more sustainable choice for your environmentally conscious projects. Choosing acoustic plywood supports reduced VOC emissions and promotes responsible forest management, enhancing long-term sustainability in construction and design.

Choosing the Right Plywood for Your Project

Acoustic plywood features enhanced sound absorption and vibration reduction properties, making it ideal for studios, theaters, and soundproofing projects, whereas standard plywood offers general structural support with versatility across various construction and furniture applications. Your choice depends on the project's primary goal: superior acoustic performance or basic strength and durability. Selecting acoustic plywood improves sound quality by minimizing noise interference, while standard plywood ensures reliable structural integrity at a lower cost.

Acoustic plywood vs standard plywood Infographic

libmatt.com

libmatt.com