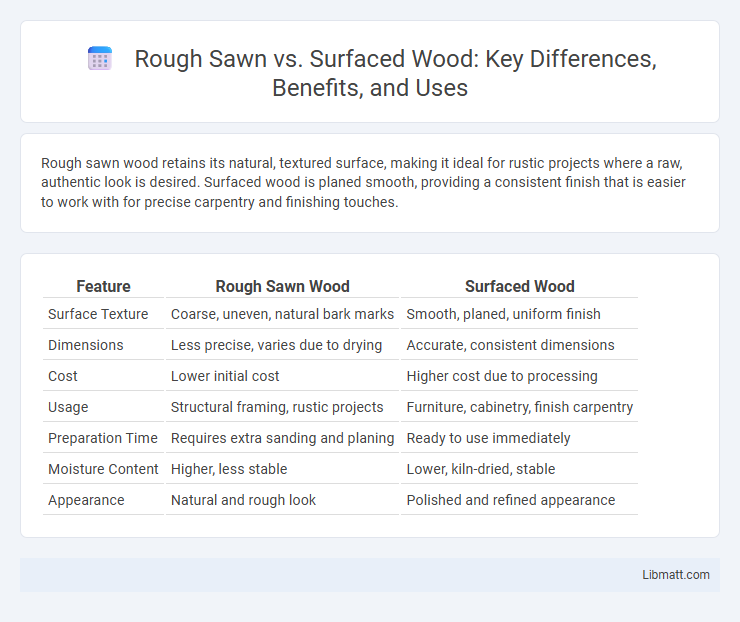

Rough sawn wood retains its natural, textured surface, making it ideal for rustic projects where a raw, authentic look is desired. Surfaced wood is planed smooth, providing a consistent finish that is easier to work with for precise carpentry and finishing touches.

Table of Comparison

| Feature | Rough Sawn Wood | Surfaced Wood |

|---|---|---|

| Surface Texture | Coarse, uneven, natural bark marks | Smooth, planed, uniform finish |

| Dimensions | Less precise, varies due to drying | Accurate, consistent dimensions |

| Cost | Lower initial cost | Higher cost due to processing |

| Usage | Structural framing, rustic projects | Furniture, cabinetry, finish carpentry |

| Preparation Time | Requires extra sanding and planing | Ready to use immediately |

| Moisture Content | Higher, less stable | Lower, kiln-dried, stable |

| Appearance | Natural and rough look | Polished and refined appearance |

Introduction to Rough Sawn and Surfaced Lumber

Rough sawn lumber refers to wood that has been cut from logs but left with a coarse, textured surface, preserving its natural appearance and dimension variability. Surfaced lumber, also known as S4S (surfaced four sides), has been planed smooth on all sides to achieve uniform thickness and a polished finish ideal for precise construction and cabinetry. Choosing between rough sawn and surfaced lumber depends on project requirements for aesthetics, durability, and ease of handling.

Defining Rough Sawn Lumber

Rough sawn lumber refers to wood that is cut directly from the log without any surface planing, retaining its coarse texture and natural saw marks. This type of lumber maintains its original thickness and dimensions, often requiring additional finishing for smoothness and precision. Used frequently in construction and rustic projects, rough sawn wood offers enhanced grip and a more authentic, rugged appearance compared to surfaced lumber.

What Is Surfaced Lumber?

Surfaced lumber, also known as S4S (surfaced four sides), is wood that has been planed on all sides to create a smooth, uniform texture, making it easier to handle and ideal for precise construction or woodworking projects. Unlike rough sawn lumber, which retains its coarse, natural texture, surfaced lumber provides consistent dimensions and a cleaner appearance, ensuring better fit and finish in your build. Its smooth surfaces also reduce splintering and make finishing treatments like painting or staining more effective.

Key Differences Between Rough Sawn and Surfaced Lumber

Rough sawn lumber retains its raw, textured surface with visible saw marks, offering a rustic appearance and increased thickness, while surfaced lumber is planed smooth on all sides for uniform dimensions and a polished finish. The moisture content tends to be higher in rough sawn lumber, impacting stability, whereas surfaced lumber is typically dried and more dimensionally stable, ideal for precise construction and finishing. Your choice depends on whether you prioritize natural aesthetics and durability or smoothness and exact measurements for your woodworking project.

Advantages of Using Rough Sawn Lumber

Rough sawn lumber offers superior strength and durability due to its thicker dimensions compared to surfaced wood, which enhances your project's structural integrity. This type of lumber retains more natural texture, providing better grip for adhesives and finishes, making it ideal for outdoor builds and rustic designs. Using rough sawn wood can also reduce costs since it requires less processing, delivering raw material value while maintaining aesthetic appeal.

Benefits of Surfaced Lumber

Surfaced lumber offers enhanced dimensional accuracy and a smoother finish, making it ideal for woodworking projects that require precise joints and a polished appearance. The planing process removes the rough outer layer, reducing the likelihood of splinters and making the wood easier to handle and finish. This type of lumber also provides a consistent thickness, which simplifies construction and improves overall structural integrity.

Common Applications for Each Type

Rough sawn lumber is commonly used in outdoor construction projects such as fencing, decking, and rustic furniture where a natural, textured appearance and durability are essential. Surfaced lumber, also known as planed or dressed wood, is ideal for interior applications like cabinetry, molding, and furniture making due to its smooth finish and precise dimensions. Your choice between rough sawn and surfaced wood impacts the aesthetic and functional qualities of your project, depending on whether you prioritize raw texture or refined appearance.

Cost Considerations: Rough Sawn vs Surfaced

Rough sawn lumber is generally more affordable than surfaced wood due to minimal processing, making it cost-effective for large projects or rustic designs. Surface planing and smoothing require additional labor and machinery, which increase the price of surfaced timber. Your choice depends on whether you prioritize budget savings or the ready-to-use finish of surfaced wood.

Choosing the Right Lumber for Your Project

Choosing the right lumber for your project depends on whether you prioritize cost, appearance, or ease of use. Rough sawn lumber retains the natural, textured surface and is often more affordable but requires extra work for smoothing and finishing. Surfaced lumber is planed to a smooth, uniform dimension, saving time and effort, making it ideal for projects demanding precision and a polished look.

Conclusion: Rough Sawn vs Surfaced Lumber

Rough sawn lumber retains its natural texture and moisture, making it ideal for projects requiring a rustic appearance or custom finishing. Surfaced lumber, also known as planed or dressed wood, offers smooth, uniform dimensions that simplify construction and finishing tasks. Your choice depends on whether you prioritize raw authenticity or ease of use and consistency in your woodworking project.

Rough sawn vs surfaced Infographic

libmatt.com

libmatt.com