Kiln dried lumber offers greater stability and reduced moisture content compared to green lumber, making it less prone to warping, shrinking, and splitting. Choosing kiln dried wood for your projects ensures stronger, more durable construction with improved finish quality.

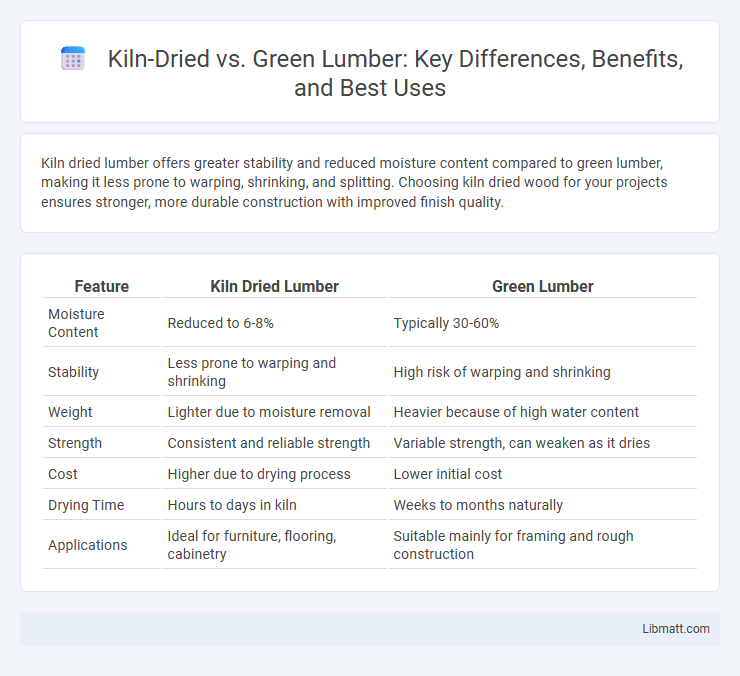

Table of Comparison

| Feature | Kiln Dried Lumber | Green Lumber |

|---|---|---|

| Moisture Content | Reduced to 6-8% | Typically 30-60% |

| Stability | Less prone to warping and shrinking | High risk of warping and shrinking |

| Weight | Lighter due to moisture removal | Heavier because of high water content |

| Strength | Consistent and reliable strength | Variable strength, can weaken as it dries |

| Cost | Higher due to drying process | Lower initial cost |

| Drying Time | Hours to days in kiln | Weeks to months naturally |

| Applications | Ideal for furniture, flooring, cabinetry | Suitable mainly for framing and rough construction |

Understanding Kiln Dried Lumber

Kiln dried lumber undergoes a controlled drying process in specialized ovens that reduces moisture content to a consistent level, typically between 6-8%, enhancing its stability and durability. This precise drying method minimizes warping, shrinkage, and susceptibility to mold compared to green lumber, which retains high moisture and is prone to these issues. Kiln drying also kills pests and fungi, making the lumber ideal for construction and indoor applications where long-term strength and appearance are critical.

What is Green Lumber?

Green lumber refers to freshly cut wood that retains a high moisture content, typically between 30% and 60%, making it heavier and more prone to warping, shrinking, and cracking as it dries. This type of lumber requires extended drying time, either naturally through air drying or artificially in kilns, to reduce moisture and stabilize the wood for construction or woodworking. Understanding the differences between green lumber and kiln dried lumber helps ensure Your projects use the appropriate wood type for strength, durability, and dimensional stability.

Moisture Content Differences

Moisture content in kiln dried lumber typically ranges between 6% and 8%, significantly lower than green lumber, which can have moisture levels exceeding 30%. This difference affects stability, as kiln dried wood experiences reduced shrinkage and warping during use. Understanding moisture content differences helps you choose the right lumber for construction or woodworking projects to ensure durability and structural integrity.

Strength and Stability Comparison

Kiln-dried lumber offers superior strength and stability compared to green lumber due to its reduced moisture content, which minimizes warping, cracking, and shrinkage. Green lumber, containing high moisture levels, is more prone to structural deformities and decay as it dries unevenly over time. Builders and contractors prefer kiln-dried wood for load-bearing applications and precision projects, ensuring consistent performance and longevity.

Workability and Machining

Kiln dried lumber offers superior workability and machining precision due to its reduced moisture content, minimizing warping, splitting, and surface roughness during cutting and shaping. Green lumber, containing higher moisture levels, often challenges machinability with increased tooling wear and less predictable dimensional stability as it dries and shrinks. Your projects benefit from kiln dried wood's enhanced consistency, delivering cleaner cuts and smoother finishes essential for detailed woodworking and joinery.

Cost Considerations

Kiln dried lumber typically costs 20-30% more than green lumber due to the energy-intensive drying process and quality control involved. Although green lumber is cheaper upfront, it may incur additional expenses in the long term from warping, shrinkage, and extended drying time on-site. Investing in kiln dried lumber reduces waste and labor costs, offering better value for precision woodworking and construction projects.

Applications and Best Uses

Kiln dried lumber offers enhanced stability and reduced moisture content, making it ideal for indoor applications such as furniture, cabinetry, and flooring where precision and durability are crucial. Green lumber, retaining higher moisture, suits outdoor projects like framing, landscaping, and temporary structures where drying occurs naturally over time. Choosing between the two depends on the specific requirements of dimensional stability, drying time, and the environmental conditions of the project.

Environmental Impact

Kiln dried lumber typically has a higher environmental impact due to the energy-intensive drying process that emits greenhouse gases. Green lumber, being freshly cut and untreated, retains more moisture but requires less energy for processing, making it a more eco-friendly option in terms of carbon footprint. Choosing green lumber can reduce your project's overall environmental impact by minimizing energy consumption and associated emissions.

Drying Time and Process

Kiln dried lumber undergoes a controlled drying process inside a kiln that typically takes several days to weeks, reducing moisture content to around 6-8%, which enhances dimensional stability and strength. Green lumber, on the other hand, contains high moisture levels and requires natural air drying, which can last several months to over a year depending on wood species and climate conditions. The kiln drying process is faster, more predictable, and prevents issues like warping and decay that are more common in green lumber during prolonged drying.

Choosing the Right Lumber for Your Project

Kiln dried lumber offers lower moisture content, making it more stable and less prone to warping or shrinking, ideal for precise woodworking projects. Green lumber retains higher moisture levels, which can lead to dimensional changes as it dries, but it is often more affordable and suitable for outdoor or structural uses where these shifts are acceptable. Choosing the right lumber for your project depends on whether you prioritize stability and finish quality or cost and environmental considerations.

Kiln dried vs green lumber Infographic

libmatt.com

libmatt.com