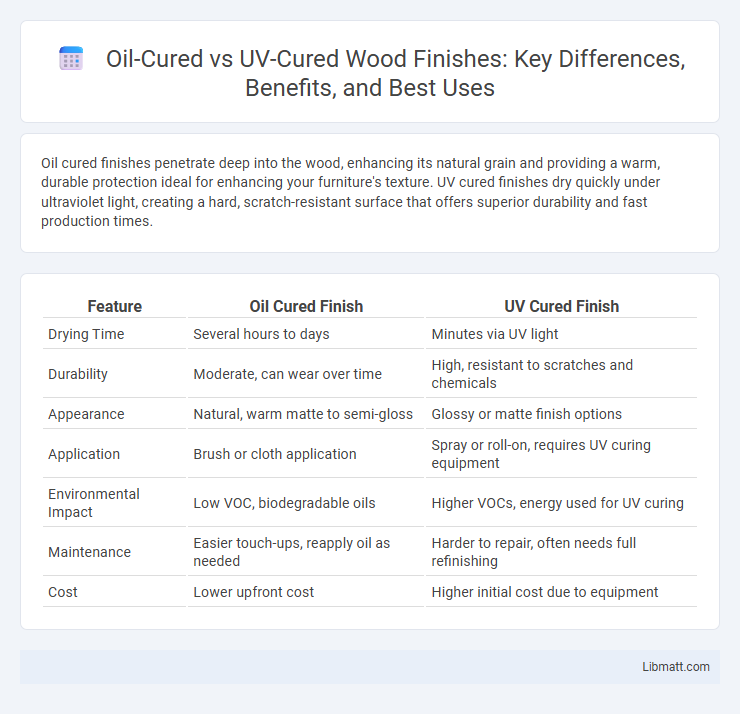

Oil cured finishes penetrate deep into the wood, enhancing its natural grain and providing a warm, durable protection ideal for enhancing your furniture's texture. UV cured finishes dry quickly under ultraviolet light, creating a hard, scratch-resistant surface that offers superior durability and fast production times.

Table of Comparison

| Feature | Oil Cured Finish | UV Cured Finish |

|---|---|---|

| Drying Time | Several hours to days | Minutes via UV light |

| Durability | Moderate, can wear over time | High, resistant to scratches and chemicals |

| Appearance | Natural, warm matte to semi-gloss | Glossy or matte finish options |

| Application | Brush or cloth application | Spray or roll-on, requires UV curing equipment |

| Environmental Impact | Low VOC, biodegradable oils | Higher VOCs, energy used for UV curing |

| Maintenance | Easier touch-ups, reapply oil as needed | Harder to repair, often needs full refinishing |

| Cost | Lower upfront cost | Higher initial cost due to equipment |

Introduction to Oil Cured and UV Cured Finishes

Oil cured finishes penetrate wood fibers, enhancing natural grain patterns while providing a durable, water-resistant surface ideal for hardwood floors and furniture. UV cured finishes use ultraviolet light to rapidly harden a polymer coating, creating a highly durable, scratch-resistant, and fast-drying layer suitable for commercial and industrial applications. Your choice between oil cured and UV cured finishes depends on the desired appearance, durability requirements, and application environment.

What is Oil Cured Finish?

Oil cured finish is a wood treatment that penetrates deeply to enhance natural grain while providing durable protection against moisture and wear. This finish uses natural oils that polymerize through oxidation, creating a hard, resilient surface ideal for furniture and flooring. Your wooden surfaces benefit from richer color and a warm glow with improved longevity when treated with an oil cured finish.

What is UV Cured Finish?

UV cured finish is a coating that hardens quickly through ultraviolet light exposure, creating a durable and resistant surface ideal for wood, metal, and plastic applications. This finishing technique offers superior hardness, chemical resistance, and faster drying times compared to traditional oil cured finishes. UV cured finishes provide a clear, glossy appearance that enhances material longevity while reducing emissions and environmental impact during curing.

Key Differences Between Oil and UV Cured Finishes

Oil cured finishes penetrate deeply into wood, enhancing natural grain and providing a warm, rich appearance with excellent durability and water resistance. UV cured finishes dry instantly through ultraviolet light exposure, creating a hard, protective surface that is highly resistant to scratches and chemicals. Your choice between oil cured and UV cured finishes depends on desired aesthetics, drying time, and the level of surface protection needed.

Application Process: Oil vs UV Cured Finishes

Oil cured finishes require multiple coats applied with a cloth or brush, allowing each layer to penetrate and dry naturally over several hours or days. UV cured finishes involve a single or fewer coats that are quickly hardened under ultraviolet light, significantly reducing drying time and increasing production efficiency. Your choice between these finishes depends on the desired durability, appearance, and application speed.

Durability and Longevity Comparison

Oil cured finishes penetrate wood fibers, providing deep protection with a natural look but generally require more frequent maintenance due to moderate resistance to wear and moisture. UV cured finishes form a hard, durable surface film through rapid polymerization, offering superior resistance to scratches, chemicals, and environmental factors, significantly extending the lifespan of wood surfaces. The enhanced hardness and faster curing time of UV finishes contribute to their greater longevity and reduced maintenance needs compared to traditional oil cured options.

Appearance and Texture: Oil vs UV Cured

Oil cured finishes offer a rich, natural appearance with a warm, deep texture that enhances the wood grain, providing a soft, matte to satin sheen. UV cured finishes create a more uniform, durable surface with a smoother, harder texture and a glossy to ultra-matte look, maintaining consistent color and clarity over time. Your choice depends on whether you prefer the organic feel and subtle variations of oil or the sleek, resilient finish of UV curing.

Environmental Impact and Safety Considerations

Oil cured finishes generally have a lower environmental impact due to their natural composition and biodegradability, making them less harmful during disposal. UV cured finishes, while offering rapid curing times and durability, often contain volatile organic compounds (VOCs) and require energy-intensive UV lamps, raising concerns about toxic emissions and energy consumption. Safety considerations for oil finishes focus on preventing spontaneous combustion of oily rags, whereas UV systems necessitate protective measures against UV radiation exposure.

Maintenance and Repair: Which is Easier?

Oil cured finishes offer easier maintenance and repair due to their penetrating properties, allowing for spot repairs without the need for complete refinishing. UV cured finishes form a hard, durable surface that resists scratches but often requires professional refinishing when damaged, making repairs more complex. Your choice depends on whether you prefer simple upkeep with oil cured or the robust protection provided by UV cured coatings.

Choosing the Right Finish for Your Project

Choosing the right finish for your project depends on factors like durability, appearance, and maintenance. Oil cured finishes penetrate deeply, enhancing wood grain and providing a natural, warm look, while UV cured finishes offer a harder, more protective surface with faster drying times. Consider your project's exposure to wear and environmental conditions to determine whether the rich texture of oil cured or the resilient, quick-drying UV cured finish best suits your needs.

Oil cured vs UV cured finish Infographic

libmatt.com

libmatt.com