LVL (Laminated Veneer Lumber) offers superior strength and stability compared to PSL (Parallel Strand Lumber) due to its layered veneer construction, making it ideal for heavy-load structural applications. Your choice between LVL and PSL should depend on specific project requirements, as PSL provides consistent strength and is often preferred for long spans and larger beams.

Table of Comparison

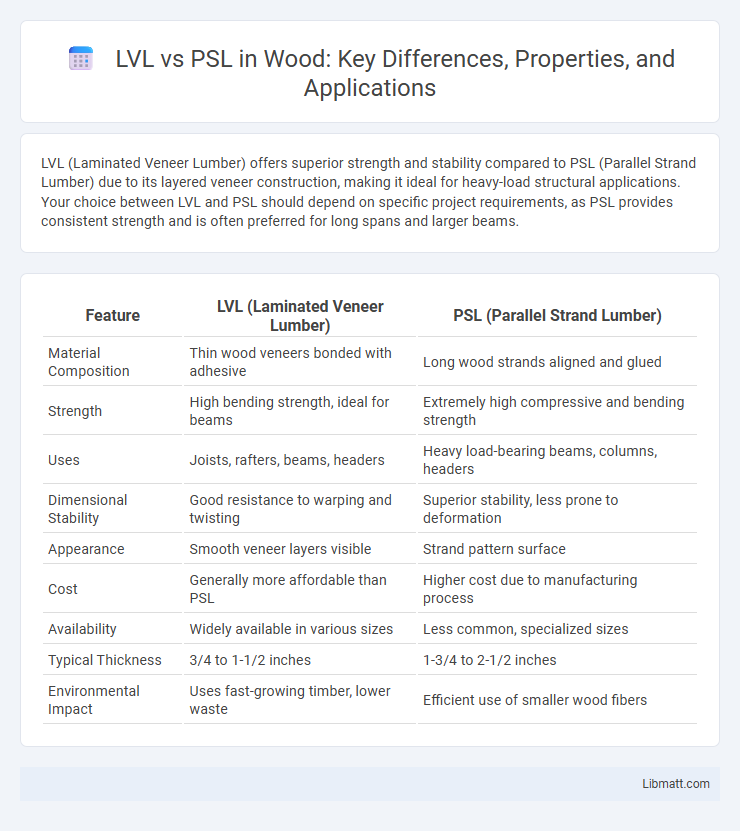

| Feature | LVL (Laminated Veneer Lumber) | PSL (Parallel Strand Lumber) |

|---|---|---|

| Material Composition | Thin wood veneers bonded with adhesive | Long wood strands aligned and glued |

| Strength | High bending strength, ideal for beams | Extremely high compressive and bending strength |

| Uses | Joists, rafters, beams, headers | Heavy load-bearing beams, columns, headers |

| Dimensional Stability | Good resistance to warping and twisting | Superior stability, less prone to deformation |

| Appearance | Smooth veneer layers visible | Strand pattern surface |

| Cost | Generally more affordable than PSL | Higher cost due to manufacturing process |

| Availability | Widely available in various sizes | Less common, specialized sizes |

| Typical Thickness | 3/4 to 1-1/2 inches | 1-3/4 to 2-1/2 inches |

| Environmental Impact | Uses fast-growing timber, lower waste | Efficient use of smaller wood fibers |

Introduction to LVL and PSL

LVL (Laminated Veneer Lumber) and PSL (Parallel Strand Lumber) are engineered wood products designed for high-strength structural applications. LVL is made by layering thin wood veneers bonded with adhesive, offering consistent strength and stability for beams and headers. PSL consists of long, parallel strands of wood glued together, providing exceptional load-bearing capacity ideal for large spans and heavy loads in construction.

What is LVL (Laminated Veneer Lumber)?

Laminated Veneer Lumber (LVL) is an engineered wood product made by layering thin wood veneers, bonded together with strong adhesives under heat and pressure. LVL offers superior strength, uniformity, and stability compared to traditional lumber, making it ideal for beams, headers, and structural applications in construction. You can rely on LVL for precise dimensional accuracy and resistance to warping or splitting, ensuring durable and reliable building components.

What is PSL (Parallel Strand Lumber)?

PSL (Parallel Strand Lumber) is an engineered wood product made by bonding together long, thin strands of wood with durable adhesives to create a strong, rigid structural beam. It offers superior load-bearing capacity and dimensional stability compared to traditional solid lumber and is commonly used in beams, headers, and columns in residential and commercial construction. PSL's uniform strength and resistance to warping make it ideal for applications where high strength and precision are required.

Manufacturing Process: LVL vs PSL

LVL (Laminated Veneer Lumber) is manufactured by bonding multiple thin wood veneers under heat and pressure, creating strong, uniform structural panels. PSL (Parallel Strand Lumber) involves aligning long wood strands parallel to each other before applying adhesive and compressing them, resulting in high-strength beams with superior load-bearing capacity. The differing manufacturing processes influence their structural properties, with LVL offering consistent stiffness and PSL providing enhanced strength for heavy-duty applications.

Structural Properties and Strength Comparison

LVL (Laminated Veneer Lumber) features consistent strength and rigidity due to its engineered wood layers bonded with adhesives, providing superior bending and shear resistance compared to PSL (Parallel Strand Lumber). PSL consists of long wood strands aligned parallel and glued together, resulting in exceptional compression strength and uniform performance ideal for heavy-load applications. Your choice between LVL and PSL should depend on specific structural requirements, with LVL excelling in flexibility and PSL dominating in load-bearing capacity.

Applications and Use Cases

LVL (Laminated Veneer Lumber) is extensively used in structural applications such as beams, headers, rim boards, and scaffolding due to its high strength-to-weight ratio and dimensional stability. PSL (Parallel Strand Lumber) excels in heavy load-bearing applications like columns, beams, and trusses, offering superior compressive strength and resistance to bending. Both engineered wood products are preferred in residential, commercial, and industrial construction for long spans and critical load points where durability and uniformity are essential.

Cost Differences and Availability

LVL (Laminated Veneer Lumber) generally costs more than PSL (Parallel Strand Lumber) due to its manufacturing process and material quality, but price variations depend on regional market demand and supply chain factors. PSL is often more readily available and suited for larger, high-load applications, offering cost efficiency for projects requiring long spans and heavy structural support. Understanding your specific project needs helps determine whether the slightly higher expense of LVL is justified by its performance benefits or if PSL's availability and pricing better align with your budget and timelines.

Sustainability and Environmental Impact

LVL (Laminated Veneer Lumber) demonstrates superior sustainability due to its efficient use of fast-growing, plantation timber which minimizes deforestation and promotes responsible forestry management. PSL (Parallel Strand Lumber) offers environmental benefits by utilizing smaller-diameter logs and wood waste, reducing solid wood consumption and landfill waste. Both LVL and PSL contribute to lower carbon footprints compared to traditional solid wood, with engineered processes that optimize material use and reduce emissions.

Installation and Workability

LVL (Laminated Veneer Lumber) offers superior dimensional stability and consistent strength, making installation faster and more precise compared to PSL (Parallel Strand Lumber), which can be heavier and more challenging to handle. PSL's dense composition requires specialized tools for cutting and fastening, potentially increasing labor time and effort on-site. You will find LVL easier to work with in complex framing projects due to its predictable performance and lighter weight.

Choosing Between LVL and PSL: Key Considerations

Choosing between LVL (Laminated Veneer Lumber) and PSL (Parallel Strand Lumber) depends on factors such as load-bearing capacity, dimensional stability, and application specifics. LVL offers high strength with consistent quality, ideal for beams and headers in residential construction, while PSL provides greater structural capacity suited for heavy load applications like long spans or columns. Evaluating project requirements, cost considerations, and supplier availability helps determine the most efficient engineered wood product.

LVL vs PSL Infographic

libmatt.com

libmatt.com