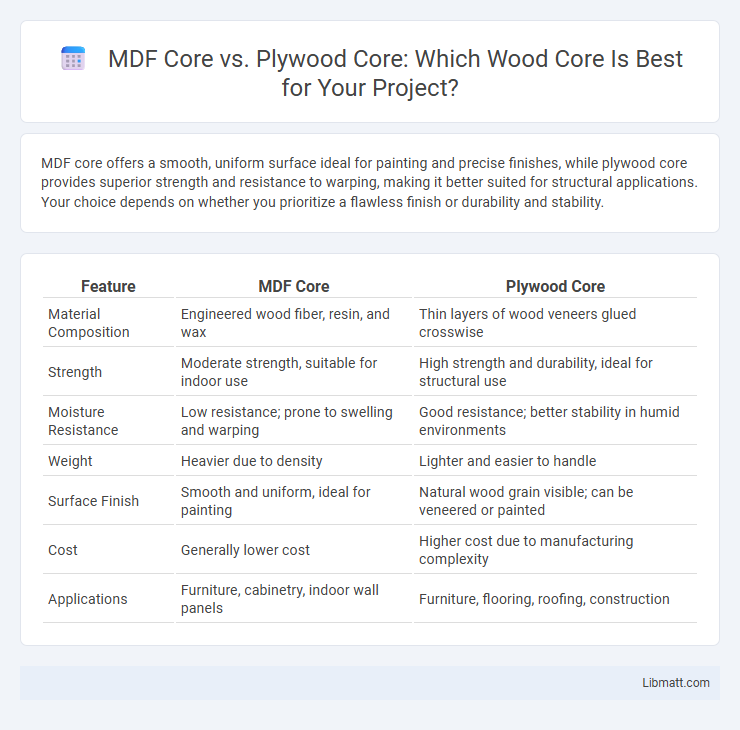

MDF core offers a smooth, uniform surface ideal for painting and precise finishes, while plywood core provides superior strength and resistance to warping, making it better suited for structural applications. Your choice depends on whether you prioritize a flawless finish or durability and stability.

Table of Comparison

| Feature | MDF Core | Plywood Core |

|---|---|---|

| Material Composition | Engineered wood fiber, resin, and wax | Thin layers of wood veneers glued crosswise |

| Strength | Moderate strength, suitable for indoor use | High strength and durability, ideal for structural use |

| Moisture Resistance | Low resistance; prone to swelling and warping | Good resistance; better stability in humid environments |

| Weight | Heavier due to density | Lighter and easier to handle |

| Surface Finish | Smooth and uniform, ideal for painting | Natural wood grain visible; can be veneered or painted |

| Cost | Generally lower cost | Higher cost due to manufacturing complexity |

| Applications | Furniture, cabinetry, indoor wall panels | Furniture, flooring, roofing, construction |

Introduction to MDF Core and Plywood Core

MDF core consists of finely ground wood fibers combined with resin to create a smooth, consistent surface ideal for painting and veneering. Plywood core is made of thin layers of wood veneers bonded together, offering superior strength and resistance to warping. Your choice between MDF core and plywood core depends on the application requirements, such as durability, finish quality, and cost efficiency.

Composition and Manufacturing Process

MDF core is made from finely ground wood fibers combined with resin and wax, then compressed under high heat and pressure to form a uniform, dense panel. Plywood core consists of multiple thin layers of wood veneer glued together with the grain of each layer running perpendicular to the adjacent one, enhancing strength and stability. The manufacturing process of MDF emphasizes fiber bonding for a smooth surface, while plywood manufacturing relies on layering veneers to resist warping and provide structural integrity.

Strength and Durability Comparison

MDF core offers a uniform density and smooth surface, making it highly stable but generally less strong and moisture-resistant than plywood core, which consists of multiple wood veneers layered for enhanced strength and flexibility. Plywood core's cross-grain construction provides superior durability and resistance to warping, making it ideal for structural applications subject to heavy loads or humidity. MDF core performs well in controlled environments but may deteriorate faster under stress or exposure to moisture compared to the more robust plywood core.

Weight Differences

MDF core boards are denser and heavier than plywood core boards, typically weighing around 50-65 pounds per 4x8 sheet, whereas plywood cores usually range from 30-45 pounds for the same size. The heavier weight of MDF cores results from tightly compressed wood fibers, providing a smoother surface ideal for painting and finishing. Plywood cores, composed of layered wood veneers, offer a lighter option with increased flexibility and resistance to warping.

Surface Smoothness and Finish Quality

MDF core panels offer superior surface smoothness compared to plywood core due to their fine, dense fibers that create a uniform, flat surface ideal for high-quality paint and veneer finishes. Plywood core, while structurally stronger, tends to have a more textured surface with visible grain patterns and potential voids, which can affect the finish quality and require additional surface preparation. For applications demanding a flawless finish and intricate detailing, MDF core is preferred, whereas plywood core suits projects where strength and durability are prioritized over surface perfection.

Moisture Resistance and Stability

MDF core offers moderate moisture resistance but tends to swell and degrade when exposed to high humidity or water, making it less stable in damp environments compared to plywood core. Plywood core features superior moisture resistance due to its cross-laminated veneer construction, enhancing stability and reducing warping or delamination risks in humid or wet conditions. For applications requiring durability and dimensional stability in moisture-prone areas, plywood core is the preferred choice over MDF core.

Cost Efficiency and Budget Considerations

MDF core panels generally offer lower material costs compared to plywood core options, making them a more budget-friendly choice for large-scale projects or budget-sensitive renovations. While plywood core panels tend to provide superior strength and moisture resistance, their higher price point can significantly impact overall project expenses. For cost-conscious consumers prioritizing affordability over durability, MDF core remains a practical solution without sacrificing basic structural integrity.

Workability and Ease of Fabrication

MDF core offers superior workability and ease of fabrication due to its dense, uniform texture, allowing for smooth cuts, drilling, and shaping without splintering or warping, making it ideal for detailed woodworking projects. Plywood core provides greater strength and resistance to moisture but can be more challenging to work with because of its layered construction, which may cause uneven edges and requires specialized tools for precise fabrication. Your choice between MDF core and plywood core should consider the balance between ease of machining and the durability needed for your specific application.

Environmental Impact and Sustainability

MDF core boards are made from wood fibers and resin, often utilizing recycled wood waste, which can reduce deforestation but may off-gas formaldehyde-based adhesives affecting indoor air quality. Plywood core consists of multiple layers of thin wood veneers, offering greater strength and durability with less chemical bonding, and can be sourced from sustainably managed forests certified by organizations like FSC. When choosing materials for your project, consider that plywood cores generally have a lower environmental impact due to renewable sourcing and longer lifespan compared to MDF cores, which require cautious disposal to minimize ecological harm.

Best Applications for MDF Core vs Plywood Core

MDF core is ideal for smooth, paint-ready surfaces and detailed molding due to its uniform density and fine texture, making it perfect for interior cabinetry and furniture where precision and finish matter most. Plywood core offers superior moisture resistance and structural strength, making it the best choice for applications exposed to humidity or requiring durability, such as kitchen cabinets, shelving, and exterior projects. Your choice between MDF and plywood core depends heavily on the environment and performance demands of your specific project.

MDF core vs Plywood core Infographic

libmatt.com

libmatt.com