Laminated veneer lumber (LVL) offers superior strength and uniformity compared to plywood, making it ideal for structural applications like beams and headers. Your choice depends on the specific load requirements and project design, as plywood provides better versatility and moisture resistance for sheathing and subflooring.

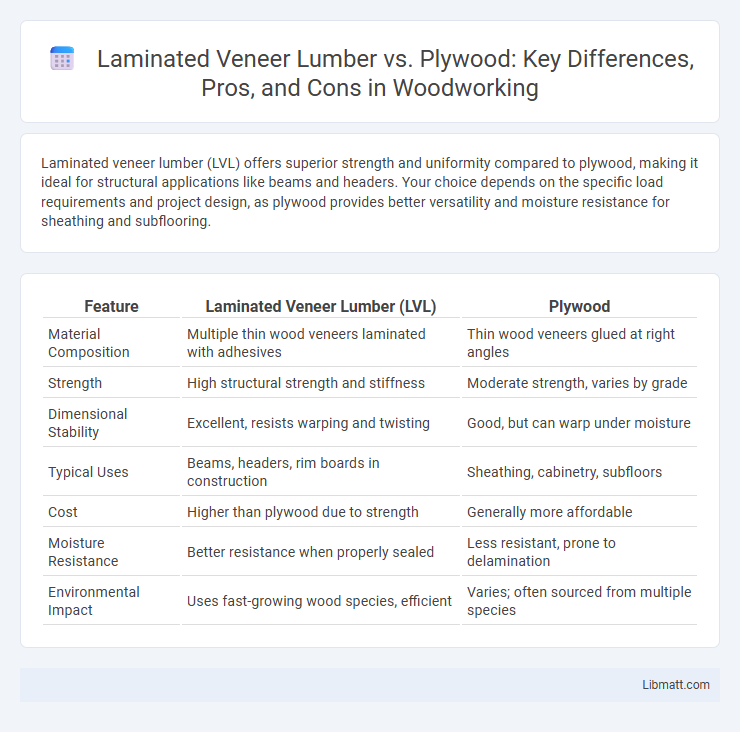

Table of Comparison

| Feature | Laminated Veneer Lumber (LVL) | Plywood |

|---|---|---|

| Material Composition | Multiple thin wood veneers laminated with adhesives | Thin wood veneers glued at right angles |

| Strength | High structural strength and stiffness | Moderate strength, varies by grade |

| Dimensional Stability | Excellent, resists warping and twisting | Good, but can warp under moisture |

| Typical Uses | Beams, headers, rim boards in construction | Sheathing, cabinetry, subfloors |

| Cost | Higher than plywood due to strength | Generally more affordable |

| Moisture Resistance | Better resistance when properly sealed | Less resistant, prone to delamination |

| Environmental Impact | Uses fast-growing wood species, efficient | Varies; often sourced from multiple species |

Overview of Laminated Veneer Lumber and Plywood

Laminated Veneer Lumber (LVL) is an engineered wood product made by layering thin wood veneers bonded with strong adhesives, offering high strength, stability, and uniformity for structural applications. Plywood consists of multiple layers of wood veneers glued together, with each layer's grain oriented perpendicular to adjacent layers, providing flexibility, resistance to warping, and versatility in construction. LVL is primarily used in beams, headers, and joists requiring significant load-bearing capacity, whereas plywood serves both structural and non-structural purposes such as sheathing, flooring, and furniture.

Composition and Manufacturing Process

Laminated veneer lumber (LVL) is composed of thin wood veneers bonded together with adhesive under heat and pressure, aligning all veneers in the same grain direction for enhanced strength and uniformity. Plywood consists of multiple layers of wood veneers glued with adjacent layers oriented at 90 degrees to each other, creating balanced strength and improved resistance to warping. Understanding these distinct manufacturing processes helps you choose the optimal panel depending on your project's load-bearing and durability requirements.

Strength and Structural Performance

Laminated veneer lumber (LVL) offers superior strength and structural performance compared to plywood due to its engineered composition of multiple wood veneers bonded under heat and pressure, providing enhanced load-bearing capacity and uniformity. LVL exhibits higher stiffness and resistance to warping, making it ideal for beams, headers, and other critical structural components where consistent performance is required. Your construction project benefits from LVL's predictable strength characteristics, ensuring greater durability and safety compared to traditional plywood panels.

Durability and Resistance to Moisture

Laminated veneer lumber (LVL) offers superior durability and resistance to moisture compared to plywood due to its engineered layering of veneers bonded with waterproof adhesives, enhancing structural stability and reducing warping. LVL's consistent grain orientation and adhesive properties create a dense, moisture-resistant material ideal for load-bearing applications exposed to varying humidity levels. Plywood, while also strong, tends to delaminate and warp more easily when exposed to prolonged moisture, making LVL the preferred choice for durability in moisture-prone environments.

Weight and Workability

Laminated veneer lumber (LVL) offers a higher strength-to-weight ratio compared to plywood, making it lighter for the same structural capacity and easier to handle on site. LVL's uniform composition provides consistent workability, allowing you to cut, nail, and fasten with minimal splitting or warping. Plywood, while heavier due to thicker plies, can be more flexible but may require additional care to prevent damage during installation.

Common Applications and Uses

Laminated veneer lumber (LVL) is commonly used in structural applications such as beams, headers, and rim boards due to its high strength and uniformity. Plywood is versatile and widely utilized in sheathing, flooring, cabinetry, and furniture because of its cross-grain construction that resists warping. Understanding your project's load-bearing and aesthetic requirements will help determine whether LVL or plywood is the better material choice.

Cost Comparison

Laminated veneer lumber (LVL) typically costs more than plywood due to its superior strength and engineered uniformity, making it a preferred choice for structural applications where load-bearing is critical. Plywood remains more budget-friendly for non-structural projects or where cost efficiency is prioritized, offering adequate durability at a lower price point. Considering Your project's requirements for strength and budget constraints will determine the optimal balance between LVL's higher cost and plywood's affordability.

Environmental Impact and Sustainability

Laminated veneer lumber (LVL) offers enhanced sustainability by utilizing thin wood veneers bonded under heat and pressure, optimizing wood usage and reducing waste compared to traditional plywood production. Plywood often involves glues with higher formaldehyde emissions, whereas LVL manufacturers increasingly adopt eco-friendly adhesives, lowering environmental impact. Choosing LVL for your construction projects supports responsible forestry practices and reduces your carbon footprint, promoting long-term environmental benefits.

Advantages of Laminated Veneer Lumber

Laminated Veneer Lumber (LVL) offers superior strength and uniformity compared to plywood, making it ideal for heavy load-bearing applications in construction. Its resistance to warping, twisting, and shrinking ensures greater structural stability and longevity. You benefit from LVL's consistent quality and enhanced dimensional accuracy, which streamline building processes and improve overall project performance.

Advantages of Plywood

Plywood offers superior resistance to warping and cracking compared to laminated veneer lumber due to its cross-grain construction, enhancing dimensional stability. Its versatility allows for easy cutting and shaping, making it suitable for a diverse range of applications from furniture to structural components. Plywood also tends to be more cost-effective and readily available, providing an economical choice for both builders and manufacturers.

Laminated veneer lumber vs plywood Infographic

libmatt.com

libmatt.com