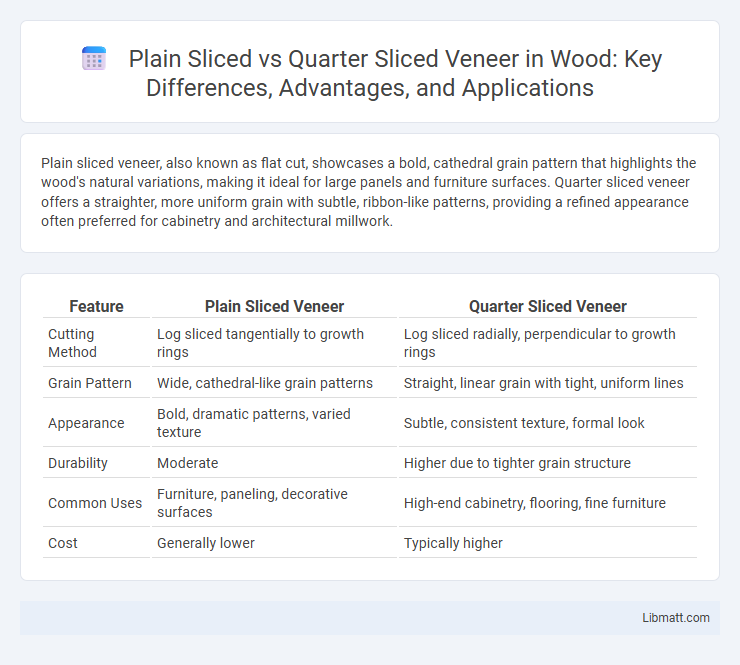

Plain sliced veneer, also known as flat cut, showcases a bold, cathedral grain pattern that highlights the wood's natural variations, making it ideal for large panels and furniture surfaces. Quarter sliced veneer offers a straighter, more uniform grain with subtle, ribbon-like patterns, providing a refined appearance often preferred for cabinetry and architectural millwork.

Table of Comparison

| Feature | Plain Sliced Veneer | Quarter Sliced Veneer |

|---|---|---|

| Cutting Method | Log sliced tangentially to growth rings | Log sliced radially, perpendicular to growth rings |

| Grain Pattern | Wide, cathedral-like grain patterns | Straight, linear grain with tight, uniform lines |

| Appearance | Bold, dramatic patterns, varied texture | Subtle, consistent texture, formal look |

| Durability | Moderate | Higher due to tighter grain structure |

| Common Uses | Furniture, paneling, decorative surfaces | High-end cabinetry, flooring, fine furniture |

| Cost | Generally lower | Typically higher |

Introduction to Wood Veneer Slicing Techniques

Plain sliced veneer, also known as flat sliced, is produced by cutting tangentially to the log, revealing a broad grain pattern with cathedral-like arches ideal for decorative surfaces. Quarter sliced veneer involves cutting the log into quarters before slicing radially, resulting in a straighter, tighter grain pattern prized for its uniform appearance and enhanced stability. Both slicing methods influence the wood's aesthetic and structural properties, guiding their selection for furniture, cabinetry, and architectural paneling.

What is Plain Sliced Veneer?

Plain sliced veneer, also known as flat cut veneer, is produced by slicing a log tangentially to the growth rings, resulting in a broad grain pattern with a cathedral or flame figure. This technique maximizes the visible grain, creating a symmetrical, natural appearance commonly used in furniture and cabinetry. Plain sliced veneer generally offers a more dramatic grain contrast compared to quarter sliced veneer, which provides a straighter, uniform pattern.

What is Quarter Sliced Veneer?

Quarter sliced veneer is produced by cutting logs into quarters before slicing them, resulting in straight grain patterns with a uniform appearance. This method reduces the visibility of growth rings and offers a more consistent texture compared to plain sliced veneer, which displays a broader, cathedral grain pattern. Quarter sliced veneer is ideal for applications requiring a refined, linear aesthetic, enhancing the elegance of your woodworking projects.

Differences in Appearance: Plain Sliced vs Quarter Sliced

Plain sliced veneer reveals a cathedral grain pattern with a more varied and wavy appearance, enhancing the natural character of the wood. Quarter sliced veneer produces a straighter, tighter grain with a linear, uniform texture that emphasizes wood rays and creates a more refined look. The choice between plain sliced and quarter sliced affects the visual aesthetics, with plain sliced offering bold, flowing patterns and quarter sliced providing subtle, elegant striping.

Manufacturing Process Comparison

Plain sliced veneer is produced by rotating the log against a blade, creating broad, cathedral grain patterns, while quarter sliced veneer involves cutting the log into quarters and slicing perpendicular to the growth rings, resulting in straighter, more uniform grain. The manufacturing process for quarter slicing requires additional log preparation and yields higher-quality veneer with consistent texture, but also generates more waste compared to plain slicing. Your choice between these veneers should consider the desired grain appearance and the efficiency of production methods.

Grain Patterns and Aesthetics

Plain sliced veneer showcases broad, cathedral-shaped grain patterns that emphasize natural wood character, creating a warm and dynamic look ideal for large surfaces. Quarter sliced veneer reveals straight, linear grain with subtle ray flecks, resulting in a refined and uniform appearance suited for formal or modern designs. Your choice between these veneers impacts the visual texture and style, balancing natural warmth against structured elegance.

Common Applications for Each Veneer Type

Plain sliced veneer is commonly used for large surfaces such as cabinet doors, wall panels, and furniture because its broad, cathedral grain patterns create a visually appealing and consistent look. Quarter sliced veneer, known for its straight, linear grain, is often selected for high-end furniture, architectural millwork, and flooring where a more uniform and refined appearance is desired. Your choice between plain sliced and quarter sliced veneer should align with the aesthetic and structural needs of your project.

Cost Factors and Availability

Plain sliced veneer typically costs less than quarter sliced veneer due to higher yield from logs and simpler processing methods, making it more widely available in various wood species. Quarter sliced veneer, involving more labor-intensive cutting to produce straight grain patterns, usually commands a premium price and is less abundant, especially in exotic hardwoods. Availability of quarter sliced veneer can be limited by log size and species, influencing both cost and procurement timelines.

Durability and Performance Considerations

Plain sliced veneer offers a more uniform grain pattern that provides consistent strength and flexibility, making it suitable for furniture and cabinetry with moderate durability requirements. Quarter sliced veneer displays tighter, straighter grain lines that generally enhance structural integrity and resist warping better, ideal for high-performance applications. Your choice depends on balancing aesthetic preferences with the needed durability and performance in the final product.

How to Choose Between Plain Sliced and Quarter Sliced Veneer

Choosing between plain sliced and quarter sliced veneer depends on the desired grain pattern and application. Plain sliced veneer offers wide, cathedral-grain patterns that showcase natural wood variations, making it ideal for decorative surfaces and furniture. Quarter sliced veneer features straighter, tighter grain lines suited for modern designs and high-traffic areas due to its enhanced durability and uniform appearance.

Plain sliced vs quarter sliced veneer Infographic

libmatt.com

libmatt.com