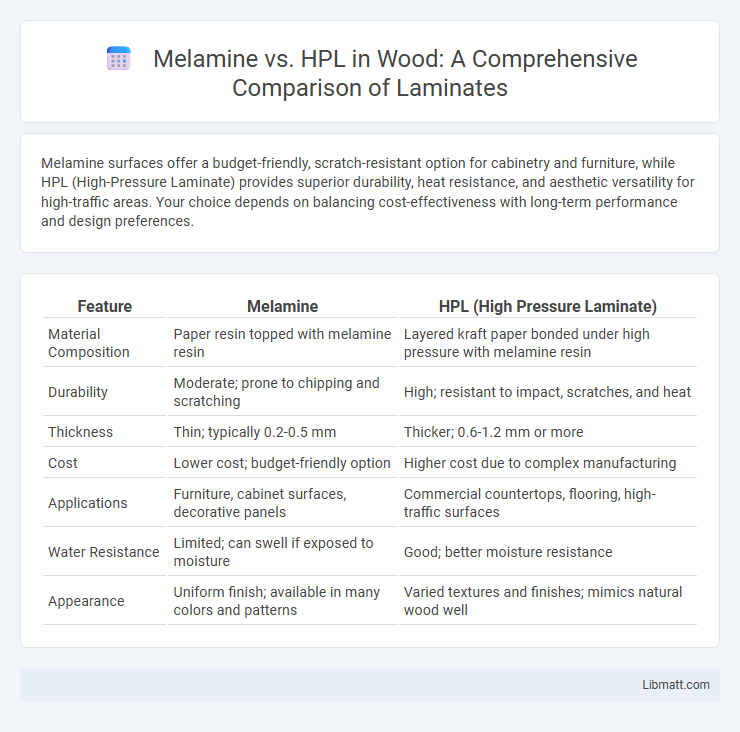

Melamine surfaces offer a budget-friendly, scratch-resistant option for cabinetry and furniture, while HPL (High-Pressure Laminate) provides superior durability, heat resistance, and aesthetic versatility for high-traffic areas. Your choice depends on balancing cost-effectiveness with long-term performance and design preferences.

Table of Comparison

| Feature | Melamine | HPL (High Pressure Laminate) |

|---|---|---|

| Material Composition | Paper resin topped with melamine resin | Layered kraft paper bonded under high pressure with melamine resin |

| Durability | Moderate; prone to chipping and scratching | High; resistant to impact, scratches, and heat |

| Thickness | Thin; typically 0.2-0.5 mm | Thicker; 0.6-1.2 mm or more |

| Cost | Lower cost; budget-friendly option | Higher cost due to complex manufacturing |

| Applications | Furniture, cabinet surfaces, decorative panels | Commercial countertops, flooring, high-traffic surfaces |

| Water Resistance | Limited; can swell if exposed to moisture | Good; better moisture resistance |

| Appearance | Uniform finish; available in many colors and patterns | Varied textures and finishes; mimics natural wood well |

Introduction to Melamine and HPL

Melamine is a durable resin-infused paper product widely used as a surface finish for furniture and cabinetry, valued for its affordability and resistance to stains and scratches. HPL (High-Pressure Laminate) is manufactured by pressing multiple layers of kraft paper impregnated with resin under high heat and pressure, providing superior durability and moisture resistance compared to melamine. Understanding the differences between your options ensures you select the right material for long-lasting, resilient surfaces in residential or commercial spaces.

Composition and Manufacturing Process

Melamine is made from a resin impregnated onto paper layers and fused under heat and pressure to create a durable decorative surface. High-Pressure Laminate (HPL) consists of multiple layers of kraft paper saturated with phenolic resin, topped with a melamine-impregnated decorative paper, all bonded together under high heat and pressure. The key difference lies in HPL's thicker, multi-layer construction, which offers enhanced durability compared to standard melamine surfaces.

Key Physical Properties Compared

Melamine surfaces offer moderate resistance to scratches and heat, making them suitable for light to medium use in residential settings, while High-Pressure Laminate (HPL) provides superior durability, with enhanced resistance to impact, abrasion, and high temperatures, ideal for commercial and heavy-use applications. Melamine sheets are thinner and less dense, contributing to a lower cost, whereas HPL's thicker, layered construction results in greater structural strength and longevity. When choosing between Melamine and HPL for your project, consider the level of wear and maintenance required to ensure optimal performance and lifespan.

Durability and Performance

Melamine surfaces offer moderate durability suited for light to medium use, with resistance to scratches and heat but limited impact strength compared to HPL. High-Pressure Laminate (HPL) delivers superior performance through enhanced resistance to abrasion, impact, moisture, and chemical exposure, making it ideal for high traffic or industrial applications. The dense resin composition in HPL ensures longer lifespan and maintains aesthetic appeal under heavy usage, outperforming standard melamine in both durability and wear resistance.

Aesthetic and Design Options

Melamine offers a wide range of colors and patterns, including wood grain and solid finishes, making it a versatile choice for budget-conscious interior designs. HPL (High Pressure Laminate) provides superior texture depth and intricate patterns, often mimicking natural materials like stone and leather, which enhances visual appeal in high-end applications. The durability and resistance of HPL allow for use in varied design schemes where long-lasting aesthetic quality is essential.

Cost Differences: Melamine vs HPL

Melamine surfaces typically cost 25-50% less than High-Pressure Laminate (HPL) due to lower production expenses and simpler manufacturing processes. HPL offers superior durability and resistance to scratches, heat, and moisture, justifying its higher price range between $30 and $60 per square foot compared to melamine's $10 to $20. Choosing between melamine and HPL depends on budget constraints and the need for long-term performance in high-traffic environments.

Applications and Best Use Cases

Melamine is ideal for budget-friendly furniture, cabinetry, and interior surfaces due to its scratch-resistant and easy-to-clean properties, making it perfect for residential and light commercial use. HPL (High-Pressure Laminate) offers superior durability and impact resistance, suited for high-traffic areas such as countertops, workstations, and healthcare facilities where longevity and hygiene are critical. Your choice should align with the specific application demands, balancing cost efficiency with durability requirements.

Maintenance and Cleaning Requirements

Melamine surfaces require minimal maintenance, typically needing only regular wiping with a damp cloth and mild detergent to prevent build-up of dirt and stains. HPL (High-Pressure Laminate) is highly durable, resisting scratches and moisture, and can withstand harsher cleaning agents without damage, making it suitable for heavy-use environments. Both materials offer easy cleaning, but HPL's enhanced resistance to chemicals and heat provides a longer-lasting, low-maintenance solution in demanding settings.

Environmental Impact and Sustainability

Melamine surfaces typically have a lower environmental footprint due to their simple manufacturing process and use of fewer resins, making them easier to recycle compared to High-Pressure Laminate (HPL). HPL offers superior durability and longevity, reducing the frequency of replacement and thus minimizing long-term resource consumption and waste. Both materials' sustainability can be enhanced by choosing products with certifications like FSC for wood sourcing and low-VOC emissions for healthier indoor air quality.

Which to Choose: Melamine or HPL?

Melamine offers an affordable, lightweight option with moderate durability, best suited for budget-conscious projects or low-traffic areas. HPL (High-Pressure Laminate) provides superior strength, resistance to scratches, heat, and impact, making it ideal for high-use surfaces and commercial settings. Evaluating your project's durability needs and budget will help you choose the right material for lasting performance.

Melamine vs HPL Infographic

libmatt.com

libmatt.com