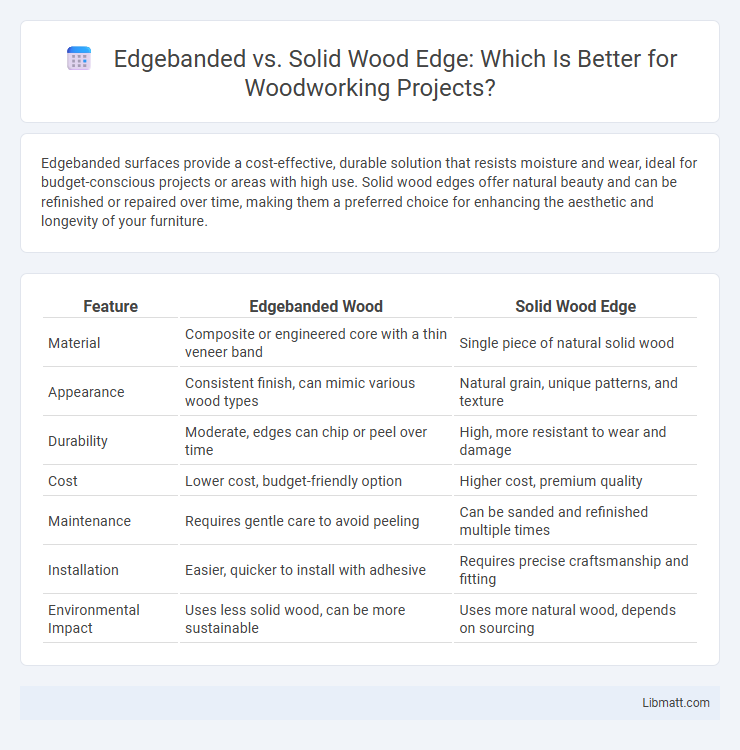

Edgebanded surfaces provide a cost-effective, durable solution that resists moisture and wear, ideal for budget-conscious projects or areas with high use. Solid wood edges offer natural beauty and can be refinished or repaired over time, making them a preferred choice for enhancing the aesthetic and longevity of your furniture.

Table of Comparison

| Feature | Edgebanded Wood | Solid Wood Edge |

|---|---|---|

| Material | Composite or engineered core with a thin veneer band | Single piece of natural solid wood |

| Appearance | Consistent finish, can mimic various wood types | Natural grain, unique patterns, and texture |

| Durability | Moderate, edges can chip or peel over time | High, more resistant to wear and damage |

| Cost | Lower cost, budget-friendly option | Higher cost, premium quality |

| Maintenance | Requires gentle care to avoid peeling | Can be sanded and refinished multiple times |

| Installation | Easier, quicker to install with adhesive | Requires precise craftsmanship and fitting |

| Environmental Impact | Uses less solid wood, can be more sustainable | Uses more natural wood, depends on sourcing |

Introduction to Edge Treatments in Woodworking

Edge treatments in woodworking play a crucial role in both aesthetics and durability, with edgebanded and solid wood edges being the most common options. Edgebanding involves applying a thin strip of material, often veneer or PVC, to cover raw edges, enhancing resistance to moisture and wear. Solid wood edges offer natural beauty and structural integrity but may require more maintenance and precise craftsmanship to avoid damage and ensure longevity for your projects.

What is Edgebanding?

Edgebanding is a thin strip of material, often made from wood veneer, PVC, or ABS, applied to the raw edges of plywood, MDF, or particleboard to create a finished, durable look that mimics solid wood. This technique enhances the surface's resistance to moisture, wear, and impact while providing a consistent aesthetic without the cost of solid wood. Your choice between edgebanded or solid wood edges depends on budget, durability needs, and desired appearance in furniture or cabinetry projects.

What is a Solid Wood Edge?

A solid wood edge is a continuous piece of natural wood applied to the edges of furniture or cabinetry, offering durability and a seamless, high-quality appearance. It provides superior resistance to wear, dents, and water damage compared to other edging options. Commonly used in premium woodworking projects, solid wood edges enhance both aesthetics and structural integrity.

Visual Differences: Edgebanded vs Solid Wood Edges

Edgebanded edges feature a thin strip of veneer or laminate applied to the core material, creating a uniform and consistent appearance, while solid wood edges show natural grain patterns and variations that add character and warmth. Solid wood edges can be sanded and refinished multiple times, enhancing durability and allowing you to maintain their aesthetic over time. Edgebanded edges often have a smoother, manufactured look, which can be ideal for modern, budget-friendly furniture designs.

Durability and Strength Comparison

Solid wood edges offer superior durability and strength due to their natural hardness and resistance to impact, making them ideal for high-traffic areas or heavy use. Edgebanded surfaces, while more cost-effective and resistant to moisture or warping, typically lack the structural integrity of solid wood, which may lead to quicker wear or damage over time. Your choice between these options should consider the balance between long-term durability and budget constraints for the intended application.

Cost Differences: Budget Considerations

Edgebanded wood edges generally offer a more cost-effective solution compared to solid wood edges due to lower material and labor expenses, making them ideal for budget-conscious projects. Solid wood edges, while more expensive, provide superior durability and a premium aesthetic that can enhance the long-term value of your furniture or cabinetry. Choosing between the two requires balancing upfront costs with desired quality and design preferences.

Installation Process: Edgebanding vs Solid Wood Edge

The installation process for edgebanded surfaces is typically faster and more cost-effective, involving the application of a thin strip of material using heat and adhesive, which creates a smooth, uniform edge without the need for extensive finishing. Solid wood edges require precise cutting, joining, and sanding to ensure a seamless fit and natural appearance, often demanding more skill and time during installation. Your choice between edgebanded and solid wood edges will impact the overall labor intensity and timeline of your woodworking or cabinetry project.

Customization and Design Flexibility

Edgebanded surfaces offer extensive customization options with a variety of edge profiles, colors, and finishes that perfectly match or contrast with the core material, allowing for precise design flexibility in modern cabinetry and furniture. Solid wood edges provide natural grain continuity and can be shaped or routed for unique, handcrafted details, enhancing organic aesthetics and durability. Choosing between edgebanded and solid wood edges depends on the desired balance of cost-efficiency, appearance customization, and long-term wear characteristics.

Maintenance and Longevity

Edgebanded surfaces require regular inspection to ensure the adhesive remains intact and edges do not peel, while solid wood edges need periodic sanding and refinishing to maintain their durability and appearance. Solid wood edges generally offer superior longevity because they can be refinished multiple times, whereas edgebanding, typically made of veneer or plastic, may wear out or delaminate over time, necessitating replacement. Proper maintenance of solid wood edges preserves the natural material's strength, making it a preferred choice for long-lasting furniture and cabinetry.

Choosing the Right Edge for Your Project

Selecting the right edge for your project depends on factors like durability, aesthetics, and budget. Edgebanded surfaces provide a cost-effective, moisture-resistant solution with consistent appearance, ideal for cabinetry and furniture with heavy usage or exposure to humidity. Solid wood edges offer unmatched natural beauty and strength, perfect for custom pieces where authenticity and long-term refinement are priorities.

Edgebanded vs solid wood edge Infographic

libmatt.com

libmatt.com