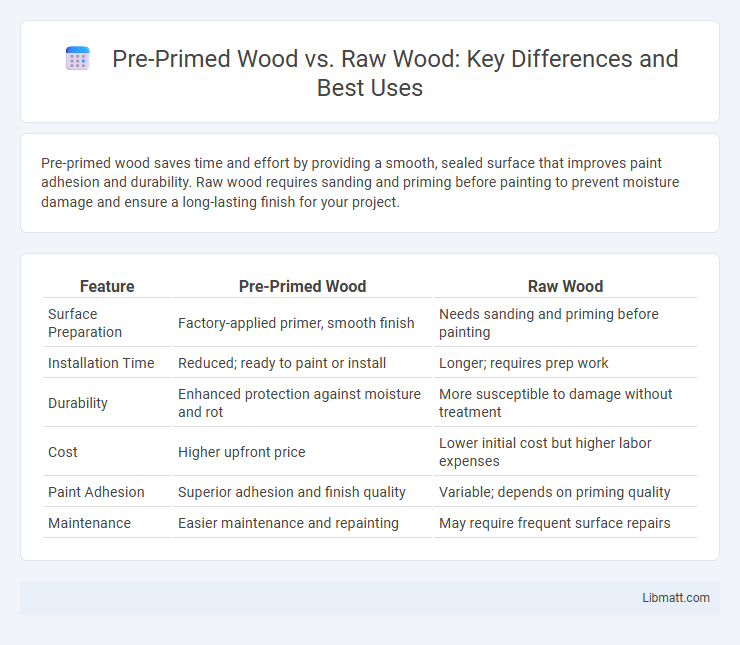

Pre-primed wood saves time and effort by providing a smooth, sealed surface that improves paint adhesion and durability. Raw wood requires sanding and priming before painting to prevent moisture damage and ensure a long-lasting finish for your project.

Table of Comparison

| Feature | Pre-Primed Wood | Raw Wood |

|---|---|---|

| Surface Preparation | Factory-applied primer, smooth finish | Needs sanding and priming before painting |

| Installation Time | Reduced; ready to paint or install | Longer; requires prep work |

| Durability | Enhanced protection against moisture and rot | More susceptible to damage without treatment |

| Cost | Higher upfront price | Lower initial cost but higher labor expenses |

| Paint Adhesion | Superior adhesion and finish quality | Variable; depends on priming quality |

| Maintenance | Easier maintenance and repainting | May require frequent surface repairs |

Introduction to Pre-Primed Wood and Raw Wood

Pre-primed wood comes pre-coated with a protective primer layer that enhances durability and saves time on preparation, making it ideal for fast, efficient projects. Raw wood, in contrast, requires sanding, priming, and sealing before painting or staining to prevent moisture damage and ensure proper adhesion. Choosing pre-primed wood can simplify your workflow and provide a smoother finish, while raw wood offers more customization options for your project needs.

What is Pre-Primed Wood?

Pre-primed wood is wood that has been factory-treated with a layer of primer, providing a smooth and consistent surface ready for painting. This treatment protects the wood from moisture and enhances paint adhesion, reducing preparation time and improving the durability of the finish. Using pre-primed wood helps you save effort and ensures a longer-lasting, professional-looking project compared to raw wood.

What is Raw Wood?

Raw wood is natural timber that has not undergone any surface treatment or finishing processes, retaining its original texture and moisture content. It requires sanding, sealing, and priming before painting or staining to ensure durability and enhanced appearance. Your choice between raw wood and pre-primed wood depends on the level of preparation you want and the time available for finishing.

Key Differences Between Pre-Primed and Raw Wood

Pre-primed wood comes factory-coated with a base layer of primer, providing immediate protection against moisture and simplifying the painting process, while raw wood requires thorough sanding, cleaning, and priming before finishing. Pre-primed wood reduces preparation time and enhances paint adhesion, making it ideal for exterior and interior projects needing durability, whereas raw wood offers greater flexibility for custom finishes but demands more labor and materials. The key differences lie in convenience, protection level, and overall cost-effectiveness during project execution.

Benefits of Using Pre-Primed Wood

Pre-primed wood offers enhanced protection against moisture, reducing the risk of warping, cracking, and rot compared to raw wood. This ready-to-use material saves You time and labor by eliminating the need for extensive surface preparation and repetitive priming coats. Using pre-primed wood results in a more uniform finish, improving paint adhesion and ensuring longer-lasting durability for outdoor and indoor projects.

Advantages of Raw Wood for Projects

Raw wood offers unparalleled flexibility for custom finishes, allowing woodworkers to choose stains, paints, or sealants that best match their project's aesthetic and environmental requirements. Its natural texture and grain remain intact, providing a richer, more authentic appearance compared to pre-primed surfaces. Furthermore, raw wood eliminates the risk of primer compatibility issues, ensuring stronger adhesion and durability for paints and finishes applied during project completion.

Applications and Best Uses for Pre-Primed Wood

Pre-primed wood is ideal for exterior and interior projects requiring quick installation and a smooth, ready-to-paint surface, such as siding, trim, and cabinetry. Its factory-applied primer enhances durability by providing a uniform base that protects against moisture and improves paint adhesion, reducing preparation time on site. Best suited for DIY projects and professional builders seeking efficiency, pre-primed wood saves labor costs and ensures consistent finish quality.

Ideal Projects for Raw Wood

Raw wood is ideal for projects requiring complete customization, such as furniture making, cabinetry, and intricate wood carving, where you control the finishing process to match your design vision. It allows you to apply stains, paints, or sealants tailored to your preferences, ensuring a unique and personalized outcome. Using raw wood is essential for outdoor projects requiring specific weatherproofing treatments customized to the environment.

Cost Comparison: Pre-Primed vs Raw Wood

Pre-primed wood carries a higher upfront cost compared to raw wood due to the added labor and materials involved in the priming process. However, choosing pre-primed wood can reduce overall expenses by minimizing the time and effort required for surface preparation and painting after purchase. Your investment in pre-primed wood often results in savings on paint, brushes, and labor costs, making it a cost-effective option for long-term projects.

Choosing the Right Wood for Your Project

Pre-primed wood offers a time-saving advantage with a smooth, sealed surface that enhances paint adhesion and durability, reducing the risk of moisture damage and warping. Raw wood requires more preparation, including sanding and priming, to prevent absorption of paint and ensure longevity, but it allows for greater customization and finishes. Selecting between pre-primed and raw wood depends on project timelines, desired finish quality, and the level of surface preparation the user is willing to perform.

Pre-primed wood vs raw wood Infographic

libmatt.com

libmatt.com