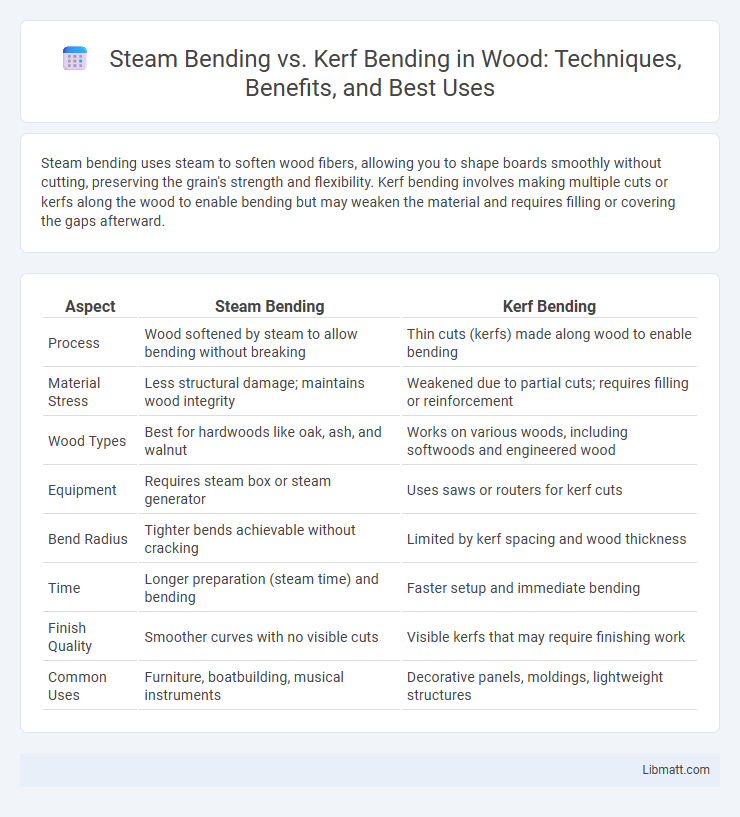

Steam bending uses steam to soften wood fibers, allowing you to shape boards smoothly without cutting, preserving the grain's strength and flexibility. Kerf bending involves making multiple cuts or kerfs along the wood to enable bending but may weaken the material and requires filling or covering the gaps afterward.

Table of Comparison

| Aspect | Steam Bending | Kerf Bending |

|---|---|---|

| Process | Wood softened by steam to allow bending without breaking | Thin cuts (kerfs) made along wood to enable bending |

| Material Stress | Less structural damage; maintains wood integrity | Weakened due to partial cuts; requires filling or reinforcement |

| Wood Types | Best for hardwoods like oak, ash, and walnut | Works on various woods, including softwoods and engineered wood |

| Equipment | Requires steam box or steam generator | Uses saws or routers for kerf cuts |

| Bend Radius | Tighter bends achievable without cracking | Limited by kerf spacing and wood thickness |

| Time | Longer preparation (steam time) and bending | Faster setup and immediate bending |

| Finish Quality | Smoother curves with no visible cuts | Visible kerfs that may require finishing work |

| Common Uses | Furniture, boatbuilding, musical instruments | Decorative panels, moldings, lightweight structures |

Introduction to Wood Bending Techniques

Steam bending uses heat and moisture to make wood pliable by softening lignin, allowing you to shape it without cutting, preserving the grain's strength. Kerf bending involves making multiple cuts (kerfs) along the wood, enabling it to bend by reducing resistance but requires filling or finishing to hide the grooves. These techniques offer different advantages: steam bending maintains structural integrity for furniture making, while kerf bending suits intricate curves in thinner pieces.

What is Steam Bending?

Steam bending is a traditional woodworking technique where wood is exposed to steam to soften its fibers, allowing it to be shaped into curves without breaking. This method is ideal for crafting furniture, boat parts, and musical instruments because it preserves the wood's natural strength and grain integrity. Compared to kerf bending, steam bending avoids cutting the wood, resulting in smoother, more durable curved pieces.

Understanding Kerf Bending

Kerf bending involves strategically cutting a series of kerfs or grooves into a material, typically wood, to create flexibility without compromising structural integrity. This technique enables sharp curves by removing sections of the material, allowing it to bend along the scored lines, unlike steam bending which softens the wood fibers with heat and moisture. Understanding kerf bending is essential for crafting precise bends in thicker or harder materials where steam bending is less effective or infeasible.

Tools and Materials Required

Steam bending requires a steam box to soften wood fibers and steam source such as a boiler or kettle, along with clamps or forms to shape the wood. Kerf bending involves using a saw or router to cut multiple kerfs or notches into the wood, requiring precision cutting tools and flexible adhesives or backing strips for stability. Both techniques demand different equipment: steam bending emphasizes moisture and heat control tools, while kerf bending relies on cutting accuracy tools and reinforcement materials.

Process Steps: Steam Bending

Steam bending involves exposing wood to steam at around 212degF for 30 to 60 minutes, softening the lignin and cellulose fibers to increase flexibility. Once pliable, the wood is quickly transferred to a form or mold where it is clamped and held until it cools and dries, solidifying the new shape. Proper ventilation, steam boxes, and moisture control are essential throughout the process to prevent cracking and ensure precise bending results.

Process Steps: Kerf Bending

Kerf bending involves making a series of closely spaced cuts, or kerfs, along the interior side of the wood to allow flexibility without breaking. After kerfing, the wood is gently bent to the desired shape, and the cuts are often filled or reinforced to maintain structural integrity. This method is preferred for thicker or harder woods that are difficult to steam bend effectively.

Advantages of Steam Bending

Steam bending offers advantages such as preserving wood grain integrity and strength by bending wood without cutting or removing material, unlike kerf bending which relies on multiple cuts to enable flexibility. It allows for smooth, continuous curves and results in less material waste, making it ideal for creating durable and aesthetically pleasing wooden components. Your projects benefit from the natural elasticity retained in steam-bent wood, enhancing both resilience and visual appeal.

Benefits of Kerf Bending

Kerf bending offers precise control over bending radius by strategically removing material to create flexible joints without the need for heat or moisture, making it ideal for hardwoods and laminates. This technique reduces the risk of surface damage and maintains material integrity, resulting in stronger, smoother bends compared to steam bending. Kerf bending also allows for complex shapes and tighter curves, enhancing design versatility in woodworking and furniture manufacturing.

Comparative Analysis: Strength, Flexibility, and Finish

Steam bending creates strong, flexible wood shapes by softening fibers with heat and moisture, resulting in smooth, continuous curves without surface damage. Kerf bending involves cutting multiple evenly spaced notches to enable bending but may weaken wood strength due to reduced cross-section and can leave visible grooves requiring filling or sanding. Your choice depends on the desired balance between structural integrity, flexibility, and the quality of the final finish in woodworking projects.

Choosing the Best Method for Your Project

Steam bending offers excellent strength and flexibility by softening wood fibers with moisture and heat, ideal for creating smooth, continuous curves in furniture and boat building. Kerf bending involves making precise cuts to allow wood to bend without breaking, suitable for tighter angles and thinner materials in cabinetry and decorative elements. Selecting the best method depends on the wood species, desired curvature, and project requirements, with steam bending favored for organic shapes and kerf bending preferred for controlled, sharp bends.

Steam bending vs Kerf bending Infographic

libmatt.com

libmatt.com