Tanalized wood uses a modern copper-based preservative that penetrates deep to protect against rot and insect damage, offering an eco-friendlier and less odorous alternative to creosote-treated timber. Your choice depends on the application, as tanalized wood is suitable for outdoor projects like decking, while creosote-treated wood is traditionally favored for heavy-duty industrial use due to its strong water resistance.

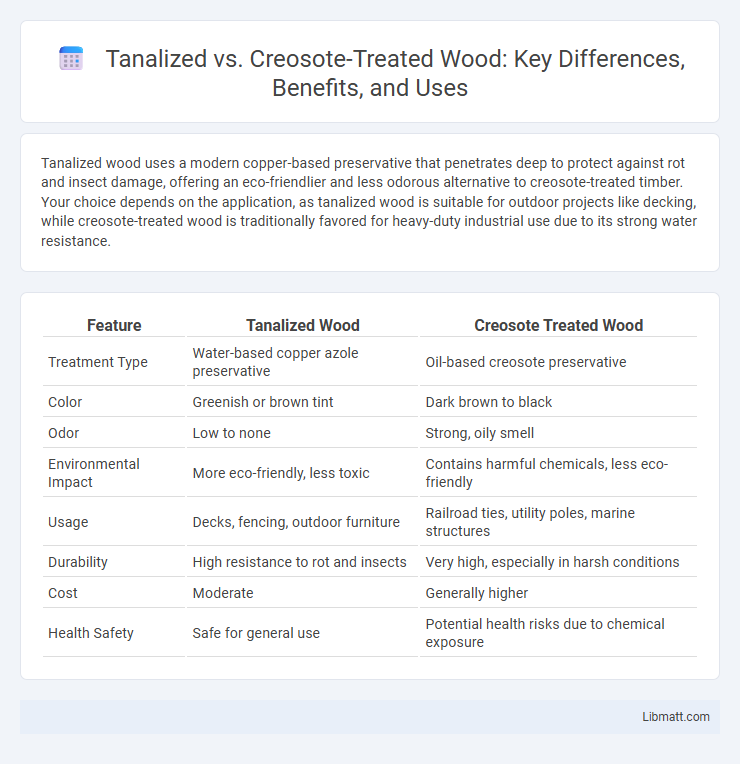

Table of Comparison

| Feature | Tanalized Wood | Creosote Treated Wood |

|---|---|---|

| Treatment Type | Water-based copper azole preservative | Oil-based creosote preservative |

| Color | Greenish or brown tint | Dark brown to black |

| Odor | Low to none | Strong, oily smell |

| Environmental Impact | More eco-friendly, less toxic | Contains harmful chemicals, less eco-friendly |

| Usage | Decks, fencing, outdoor furniture | Railroad ties, utility poles, marine structures |

| Durability | High resistance to rot and insects | Very high, especially in harsh conditions |

| Cost | Moderate | Generally higher |

| Health Safety | Safe for general use | Potential health risks due to chemical exposure |

Overview: Tanalized vs Creosote Treated Timber

Tanalized timber undergoes a pressure treatment with water-based preservatives, making it resistant to rot, insects, and fungal decay, suitable for garden furniture and structural uses. Creosote-treated timber is impregnated with a petroleum-based preservative, providing long-lasting protection particularly for railway sleepers and marine environments, but it has a strong odor and is not recommended for close human contact. Understanding these differences helps you choose the right treated timber based on environmental exposure and intended application.

What is Tanalized Timber?

Tanalized timber is wood that has been pressure-treated with preservatives, primarily copper-based compounds, to protect against rot, fungi, and insect damage, making it ideal for outdoor and structural use. This treatment penetrates deeply into the wood fibers, ensuring long-lasting durability in damp or exposed environments without the strong chemical odor associated with creosote. You can choose tanalized timber for safer, environmentally friendly construction projects that require robust weather resistance and minimal maintenance.

What is Creosote Treated Timber?

Creosote treated timber is wood preserved using a coal-tar based substance that penetrates deeply to protect against rot, fungi, and insect damage. This treatment is commonly applied to railway sleepers, utility poles, and marine structures due to its durability and water resistance. Your choice between creosote treated timber and alternatives like Tanalized depends on the specific environmental exposure and safety considerations.

Key Differences Between Tanalized and Creosote Treatments

Tanalized treatment uses water-based preservatives with copper compounds, providing protection against fungi and insects while being environmentally safer and suitable for residential use. Creosote treatment involves coal tar oil, offering strong protection against decay and marine borers but has a strong odor and is primarily used for industrial applications like railway sleepers and utility poles. The key differences lie in their chemical composition, environmental impact, application areas, and safety regulations governing their use.

Chemical Composition and Safety Considerations

Tanalized wood is treated with copper-based preservatives like copper azole, which provide effective protection against rot and insect damage while being safer for residential use due to lower toxicity levels. Creosote-treated wood contains coal tar derivatives, making it highly effective for industrial applications but posing significant health and environmental risks due to its carcinogenic compounds. Your choice should consider that Tanalized timber is approved for gardens and playgrounds, whereas creosote-treated wood is restricted to industrial or marine use due to its hazardous chemical composition.

Durability and Lifespan Comparison

Tanalized wood, treated with copper azole preservatives, offers enhanced resistance against rot, insect attack, and fungal decay, extending its lifespan up to 40 years in ground contact. Creosote-treated timber, primarily used for heavy-duty outdoor applications like railway sleepers and utility poles, provides excellent durability but can last around 25 to 30 years depending on environmental exposure. Tanalized wood is safer for residential use due to lower toxicity, while creosote-treated wood's chemical profile limits its application despite its robust protective properties.

Environmental Impact and Regulations

Tanalized wood uses water-based preservatives with copper compounds, making it less harmful to the environment compared to creosote-treated timber, which contains coal tar chemicals known for toxicity and soil contamination risks. Regulations often restrict creosote-treated wood use to industrial applications due to its environmental hazards, while Tanalized wood complies with stricter environmental standards for residential and commercial projects. Choosing Tanalized products supports sustainable construction practices and aligns with current environmental regulations, ensuring Your project minimizes ecological impact.

Applications and Recommended Uses

Tanalized timber, treated with copper azole or similar preservatives, is widely used for outdoor structures such as decking, fencing, and garden furniture due to its resistance to rot and insect attack while being safe for residential environments. Creosote-treated wood is primarily employed in heavy-duty applications like railway sleepers, utility poles, and marine pilings, where deep penetration and resistance to harsh weather and marine organisms are critical, but it is not recommended for residential or garden use because of its strong odor and toxicity. Choosing between these treatments depends on the intended exposure conditions and safety requirements, with Tanalized favored for consumer safety and creosote for industrial durability.

Cost Analysis: Tanalized vs Creosote Treated Wood

Tanalized wood generally costs more upfront than creosote treated wood due to its advanced water-based preservative treatment that offers superior environmental safety and long-term durability. Creosote treated wood tends to be less expensive initially but may incur higher maintenance and replacement costs over time because it is less resistant to environmental wear and poses health and environmental concerns. Choosing Tanalized wood can be a more cost-effective investment for Your projects when factoring in longevity, reduced maintenance, and compliance with safety standards.

Choosing the Right Treatment for Your Project

Tanalized wood offers eco-friendly protection through water-based preservatives, making it ideal for residential projects where safety and sustainability are priorities. Creosote treatment provides robust, long-lasting resistance to decay and insects, best suited for heavy-duty industrial or outdoor applications like railway sleepers and utility poles. Your choice depends on the project's exposure level, environmental impact, and required durability to ensure optimal wood preservation.

Tanalized vs creosote treated Infographic

libmatt.com

libmatt.com