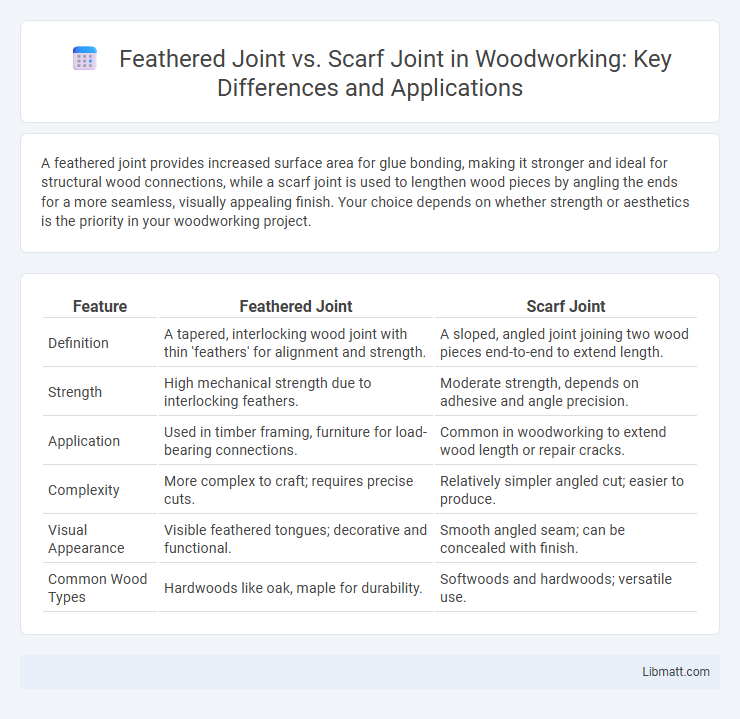

A feathered joint provides increased surface area for glue bonding, making it stronger and ideal for structural wood connections, while a scarf joint is used to lengthen wood pieces by angling the ends for a more seamless, visually appealing finish. Your choice depends on whether strength or aesthetics is the priority in your woodworking project.

Table of Comparison

| Feature | Feathered Joint | Scarf Joint |

|---|---|---|

| Definition | A tapered, interlocking wood joint with thin 'feathers' for alignment and strength. | A sloped, angled joint joining two wood pieces end-to-end to extend length. |

| Strength | High mechanical strength due to interlocking feathers. | Moderate strength, depends on adhesive and angle precision. |

| Application | Used in timber framing, furniture for load-bearing connections. | Common in woodworking to extend wood length or repair cracks. |

| Complexity | More complex to craft; requires precise cuts. | Relatively simpler angled cut; easier to produce. |

| Visual Appearance | Visible feathered tongues; decorative and functional. | Smooth angled seam; can be concealed with finish. |

| Common Wood Types | Hardwoods like oak, maple for durability. | Softwoods and hardwoods; versatile use. |

Introduction to Timber Joining Techniques

Feathered joints and scarf joints are essential timber joining techniques used in woodworking and construction to create strong, seamless connections between wood pieces. Feathered joints involve multiple thin, overlapping "feathers" or tongues that increase surface area for glue adhesion, enhancing joint strength. Scarf joints use angled or tapered cuts to join timber ends, offering structural stability and an aesthetically smooth finish, making them ideal for lengthening beams or repairing damaged wood.

What is a Feathered Joint?

A Feathered joint is a woodworking connection where thin, tapered extensions on the end of one piece fit into corresponding grooves on another piece, creating a seamless and strong bond. This joint is primarily used to align and reinforce edges, preventing gaps and ensuring structural integrity in furniture or cabinetry. Compared to a Scarf joint, which overlaps two tapered ends, the Feathered joint provides precise alignment with minimal visible joins.

What is a Scarf Joint?

A scarf joint is a woodworking technique used to join two pieces of wood end-to-end by tapering or beveling their ends to create an overlapping, angled connection that increases surface area for bonding. This joint provides enhanced strength and stability in structural applications, such as in timber framing or boat building. Compared to a feathered joint, the scarf joint offers superior resistance to tension and shear forces due to its elongated, interlocking design.

Historical Uses of Feathered and Scarf Joints

Feathered joints have been historically utilized in wooden shipbuilding for their ability to securely overlap planks, ensuring watertight seals critical in maritime construction. Scarf joints found extensive application in timber framing and traditional carpentry, enabling the extension of beams and structural members while maintaining strength and alignment. Both joints reflect centuries of craftsmanship adapted to the demands of building durability and material efficiency in historical architecture and transportation.

Structural Strength Comparison

Feathered joints provide enhanced structural strength by overlapping wooden components, distributing loads more evenly and reducing stress concentrations. In contrast, scarf joints, characterized by angled cuts, offer moderate strength primarily suited for aligning and extending timber lengths but may require reinforcement under heavy loads. Engineering tests demonstrate feathered joints resist shear and bending forces more effectively, making them preferable in high-stress applications like timber framing and boatbuilding.

Crafting Process: Feathered Joint vs Scarf Joint

The crafting process of a feathered joint involves precisely tapering one piece of wood into thin, flexible "feathers" that overlap and interlock with a corresponding notch on the adjoining piece, providing a strong mechanical bond ideal for angled or curved connections. In contrast, a scarf joint requires carefully cutting complementary bevels at matching angles on both wood pieces, then joining them edge-to-edge with adhesive or fasteners to create a smooth, elongated surface ideal for extending wood lengths. Your choice between these joints depends on the specific structural demands and aesthetic goals of your woodworking project.

Applications in Modern Woodworking

Feathered joints and scarf joints both play crucial roles in modern woodworking, with feathered joints primarily used for aligning and strengthening thin wooden panels or veneers. Scarf joints excel in creating long, continuous workpieces by joining two shorter lumber sections end-to-end, essential for beams and molding in construction and furniture making. Your choice depends on whether you need precise edge alignment or extended length for structural and aesthetic woodworking applications.

Pros and Cons of Feathered Joints

Feathered joints provide a strong mechanical interlock by increasing the gluing surface area, making them ideal for joining timber in woodworking and construction. Their precision fit minimizes visible seams, enhancing aesthetic appeal, but the complexity of cutting feathered joints requires skilled craftsmanship and specialized tools. You benefit from durable, stable joints, though the time and effort involved may not suit all projects.

Pros and Cons of Scarf Joints

Scarf joints offer a strong, seamless connection by overlapping two pieces of wood, making them suitable for extending lengths or repairing timber with minimal bulk. They provide greater surface area for adhesive, resulting in increased joint strength compared to simpler butt joints, but require precise cutting and skilled craftsmanship to ensure proper alignment. You may experience challenges with the complexity of creating scarf joints, as improper execution can lead to weaker bonds and increased susceptibility to shear forces.

Choosing the Right Joint for Your Project

When choosing between a feathered joint and a scarf joint, consider the strength and aesthetics required for your project. Feathered joints offer precise edge alignment ideal for delicate, lightweight frames, while scarf joints provide enhanced structural integrity for longer, load-bearing applications. Your selection should balance the need for durability with the desired appearance to ensure a professional finish.

Feathered joint vs Scarf joint Infographic

libmatt.com

libmatt.com