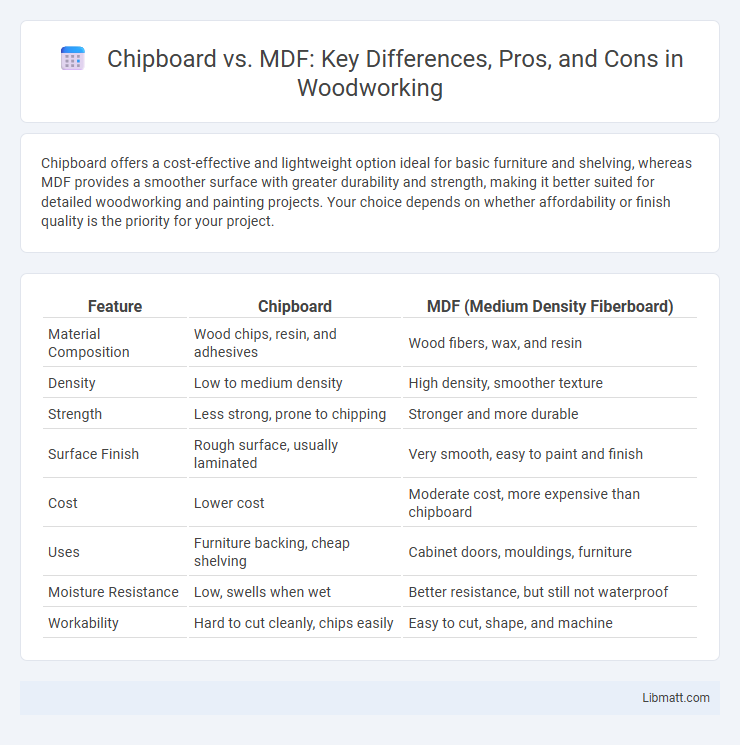

Chipboard offers a cost-effective and lightweight option ideal for basic furniture and shelving, whereas MDF provides a smoother surface with greater durability and strength, making it better suited for detailed woodworking and painting projects. Your choice depends on whether affordability or finish quality is the priority for your project.

Table of Comparison

| Feature | Chipboard | MDF (Medium Density Fiberboard) |

|---|---|---|

| Material Composition | Wood chips, resin, and adhesives | Wood fibers, wax, and resin |

| Density | Low to medium density | High density, smoother texture |

| Strength | Less strong, prone to chipping | Stronger and more durable |

| Surface Finish | Rough surface, usually laminated | Very smooth, easy to paint and finish |

| Cost | Lower cost | Moderate cost, more expensive than chipboard |

| Uses | Furniture backing, cheap shelving | Cabinet doors, mouldings, furniture |

| Moisture Resistance | Low, swells when wet | Better resistance, but still not waterproof |

| Workability | Hard to cut cleanly, chips easily | Easy to cut, shape, and machine |

Introduction to Chipboard and MDF

Chipboard and MDF are engineered wood products commonly used in furniture and construction due to their affordability and versatility. Chipboard consists of wood chips, sawdust, and resin compressed into sheets, while MDF is made from finely ground wood fibers combined with wax and resin for a smoother, denser finish. Understanding the differences between chipboard and MDF helps you select the right material for your project based on strength, texture, and cost considerations.

Composition and Manufacturing Process

Chipboard is made from wood chips, sawmill shavings, and resin bonded together under heat and pressure, resulting in a dense and rigid panel ideal for cost-effective furniture construction. MDF (Medium-Density Fiberboard) consists of fine wood fibers combined with wax and resin, compressed at high temperatures to create a smooth, uniform surface suitable for intricate machining and painting. Understanding the distinct composition and manufacturing process helps you choose the right engineered wood product for your project's durability and finish requirements.

Cost Comparison: Chipboard vs MDF

Chipboard is generally more affordable than MDF due to its manufacturing process using recycled wood particles and adhesives, making it a budget-friendly choice for furniture and cabinetry. MDF, while slightly higher in cost, offers greater density, smoothness, and durability, justifying its price for applications requiring a refined finish and strength. The cost difference varies by thickness and supplier, with chipboard favored for cost-sensitive projects and MDF preferred when quality and finish are prioritized.

Strength and Durability Differences

Chipboard, made from compressed wood particles bonded with resin, offers moderate strength but tends to be less durable under heavy loads or moisture exposure compared to MDF. Medium Density Fiberboard (MDF) is denser and smoother due to its finer wood fibers, providing superior strength, stability, and resistance to warping, making it ideal for high-impact furniture and cabinetry. MDF's enhanced durability also results from its uniform composition, which allows for better screw holding and smoother finishes.

Workability and Ease of Use

Chipboard offers moderate workability due to its rough texture and lower density, making it ideal for simple furniture and basic construction projects. MDF, with its smooth surface and uniform density, allows for more precise cutting, drilling, and shaping, providing greater ease of use for detailed woodworking and intricate designs. Your choice depends on the level of finish and complexity required, with MDF being preferable for refined work.

Surface Finish and Appearance

Chipboard features a rougher surface with visible wood chips, often requiring laminates or veneers for a smooth, polished finish suitable for furniture and cabinetry. MDF (Medium Density Fiberboard) offers a finer, smoother surface ideal for painting or laminating, resulting in a sleek, uniform appearance preferred in high-quality interior applications. The denser composition of MDF allows for better edge finishing and detailed CNC machining, enhancing its aesthetic versatility compared to chipboard.

Moisture Resistance and Stability

Chipboard is less moisture-resistant than MDF due to its larger wood particles, which absorb water more easily and cause swelling or warping. MDF offers superior stability and moisture resistance because of its fine, densely packed fibers and resin binders that minimize water absorption. You should choose MDF for applications requiring higher durability in humid environments or where precise, stable surfaces are essential.

Environmental Impact and Sustainability

Chipboard, made from wood chips and resin, generally has a lower environmental impact due to its use of recycled wood waste, making it a more sustainable option compared to MDF, which is produced from wood fibers and often involves formaldehyde-based adhesives. MDF tends to have higher energy consumption during manufacturing and can release volatile organic compounds (VOCs), affecting indoor air quality. Choosing chipboard can support eco-friendly practices by promoting the reuse of materials and reducing reliance on virgin wood sources.

Common Applications in Furniture and Construction

Chipboard is widely used in budget-friendly furniture such as flat-pack cabinets, shelving, and underlayment due to its cost-effectiveness and decent strength. MDF (Medium-Density Fiberboard) is favored for high-quality furniture, intricate moldings, and interior panels because of its smooth surface and superior machinability. In construction, chipboard serves as subflooring and wall sheathing, while MDF's moisture-resistant variants are ideal for decorative wall panels and door cores.

Choosing Between Chipboard and MDF

Choosing between chipboard and MDF depends on your project's structural needs and budget constraints. MDF offers a smoother finish and greater density, making it ideal for detailed woodworking and painting, while chipboard is more affordable and suitable for lightweight furniture or shelving. Your decision should consider durability, moisture resistance, and the type of finish required to ensure optimal performance and aesthetics.

Chipboard vs MDF Infographic

libmatt.com

libmatt.com