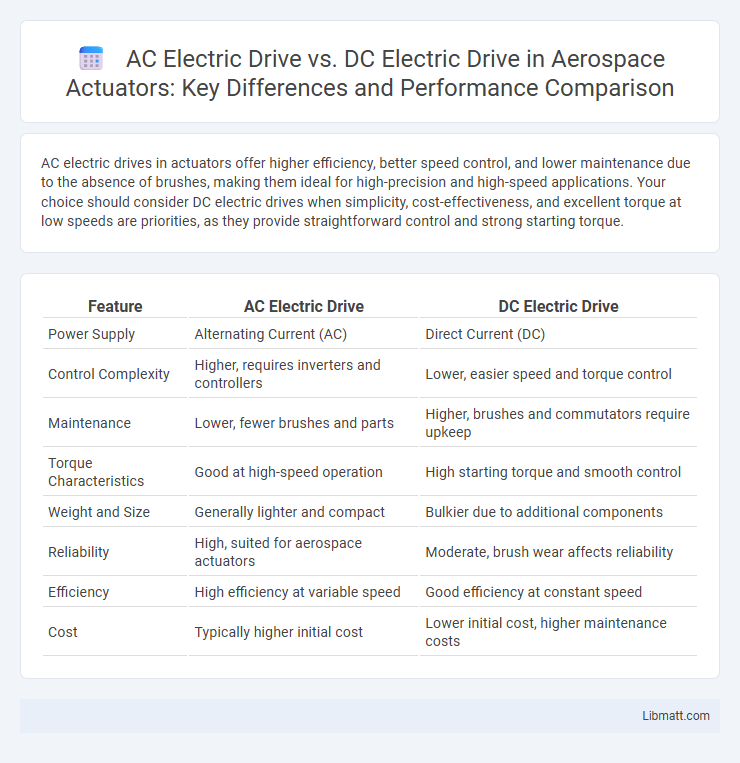

AC electric drives in actuators offer higher efficiency, better speed control, and lower maintenance due to the absence of brushes, making them ideal for high-precision and high-speed applications. Your choice should consider DC electric drives when simplicity, cost-effectiveness, and excellent torque at low speeds are priorities, as they provide straightforward control and strong starting torque.

Table of Comparison

| Feature | AC Electric Drive | DC Electric Drive |

|---|---|---|

| Power Supply | Alternating Current (AC) | Direct Current (DC) |

| Control Complexity | Higher, requires inverters and controllers | Lower, easier speed and torque control |

| Maintenance | Lower, fewer brushes and parts | Higher, brushes and commutators require upkeep |

| Torque Characteristics | Good at high-speed operation | High starting torque and smooth control |

| Weight and Size | Generally lighter and compact | Bulkier due to additional components |

| Reliability | High, suited for aerospace actuators | Moderate, brush wear affects reliability |

| Efficiency | High efficiency at variable speed | Good efficiency at constant speed |

| Cost | Typically higher initial cost | Lower initial cost, higher maintenance costs |

Introduction to Electric Drives in Actuators

AC and DC electric drives in actuators provide distinct advantages based on their operational principles. AC drives excel in efficiency, low maintenance, and smooth speed control due to their use of alternating current and advanced inverter technologies. Your choice between AC and DC electric drives should consider factors like torque requirements, control precision, and power source compatibility for optimal actuator performance.

Overview of AC Electric Drives

AC electric drives use alternating current motors, commonly asynchronous or synchronous types, offering improved energy efficiency and reduced maintenance compared to DC drives. These systems excel in variable speed applications, providing precise control and smoother acceleration in actuators across industrial automation. Your choices in actuators benefit from the robustness and cost-effectiveness of AC drives, especially in applications requiring high power and reliability.

Overview of DC Electric Drives

DC electric drives in actuators offer precise speed and torque control due to their straightforward design and excellent response characteristics. They are commonly used in applications requiring variable speed and high starting torque, such as robotics and conveyors. Your choice of a DC electric drive can enhance actuator performance with reliable operation and simple maintenance compared to AC alternatives.

Key Differences Between AC and DC Drives

AC electric drives in actuators offer superior speed control through variable frequency drives, enabling smoother operation and higher efficiency, whereas DC electric drives provide precise torque control with simpler design and easier maintenance. AC drives typically exhibit higher durability and lower cost of ownership due to robust construction and less frequent brush replacements common in DC drives. The choice between AC and DC drives depends on application requirements, with AC drives favored for high power and variable speed needs, and DC drives preferred for applications demanding precise torque at low speeds.

Efficiency Comparison: AC vs. DC Drives

AC electric drives typically offer higher efficiency in actuators due to lower power losses and improved heat dissipation, making them ideal for continuous operation and dynamic load conditions. DC electric drives provide precise speed control and high starting torque but often suffer from lower efficiency due to brush friction and commutation losses. Choosing your drive depends on the application requirements, balancing efficiency with control precision.

Control and Precision Capabilities

AC electric drives in actuators offer superior control flexibility and higher precision due to advanced vector control techniques and real-time feedback systems. DC electric drives provide simpler and cost-effective control with inherently smooth speed regulation, but they typically lack the fine-tuned precision available in AC drives. Your choice depends on the required accuracy and responsiveness for the specific actuator application.

Cost Analysis and Maintenance Requirements

AC electric drives typically offer lower upfront costs and higher energy efficiency compared to DC drives, making them cost-effective for long-term use in actuators. Maintenance requirements for AC drives are generally less intensive due to the absence of brushes and commutators, reducing wear and tear and downtime. Your choice between AC and DC electric drives should consider these factors, balancing initial investment with ongoing operational expenses.

Application Suitability in Industrial Automation

AC electric drives excel in industrial automation with high-speed and precision control for applications like conveyor systems and robotic arms, benefiting from their robust performance and low maintenance. DC electric drives offer superior torque control and are preferable for applications requiring variable speed and high starting torque, such as cranes and hoists. Both drive types play crucial roles but are selected based on specific actuator requirements, including load dynamics and control complexity.

Reliability and Durability Factors

AC electric drives in actuators offer higher reliability due to fewer brush and commutator components, resulting in reduced wear and maintenance compared to DC drives. DC electric drives, while providing excellent torque control, are more susceptible to failures from brush wear and commutator degradation, impacting long-term durability. Your actuator choice should consider the operating environment and maintenance capability, with AC drives generally delivering better longevity in industrial applications requiring high reliability.

Future Trends in Electric Actuator Drives

Future trends in electric actuator drives emphasize the increasing adoption of AC electric drives due to their superior efficiency, reliability, and lower maintenance compared to DC electric drives. Advancements in power electronics and control algorithms enhance the precision and energy savings in AC drives, making them ideal for smart automation in industries and robotics. Your choice of actuator drive should consider these innovations, as AC drives are becoming the preferred solution for scalable and environmentally friendly applications.

AC electric drive vs DC electric drive (in actuators) Infographic

libmatt.com

libmatt.com