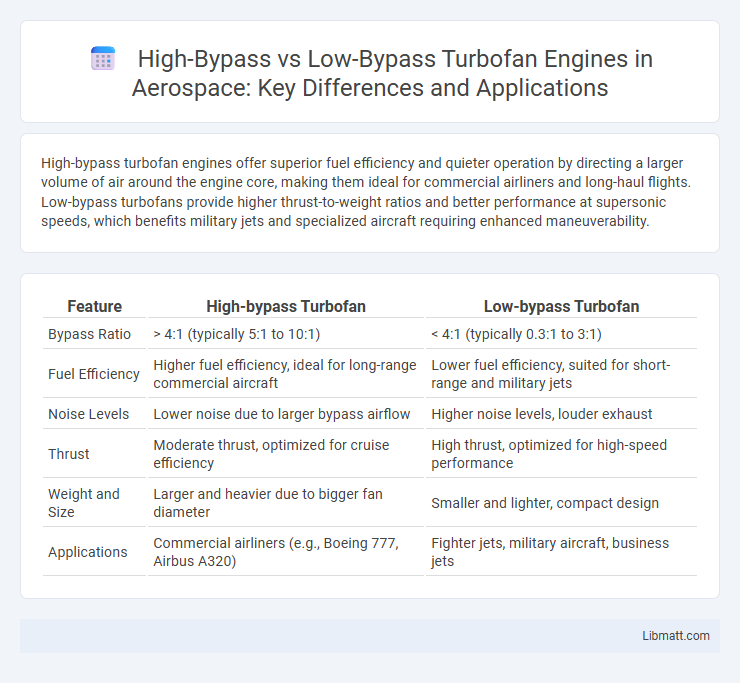

High-bypass turbofan engines offer superior fuel efficiency and quieter operation by directing a larger volume of air around the engine core, making them ideal for commercial airliners and long-haul flights. Low-bypass turbofans provide higher thrust-to-weight ratios and better performance at supersonic speeds, which benefits military jets and specialized aircraft requiring enhanced maneuverability.

Table of Comparison

| Feature | High-bypass Turbofan | Low-bypass Turbofan |

|---|---|---|

| Bypass Ratio | > 4:1 (typically 5:1 to 10:1) | < 4:1 (typically 0.3:1 to 3:1) |

| Fuel Efficiency | Higher fuel efficiency, ideal for long-range commercial aircraft | Lower fuel efficiency, suited for short-range and military jets |

| Noise Levels | Lower noise due to larger bypass airflow | Higher noise levels, louder exhaust |

| Thrust | Moderate thrust, optimized for cruise efficiency | High thrust, optimized for high-speed performance |

| Weight and Size | Larger and heavier due to bigger fan diameter | Smaller and lighter, compact design |

| Applications | Commercial airliners (e.g., Boeing 777, Airbus A320) | Fighter jets, military aircraft, business jets |

Introduction to Turbofan Engines

Turbofan engines dominate modern aviation propulsion with high-bypass models offering superior fuel efficiency and quieter operation by channeling a large volume of air around the core engine. Low-bypass turbofans prioritize higher thrust and speed, making them ideal for military and supersonic aircraft. The bypass ratio, key to performance differences, measures the mass of air bypassing the engine core compared to the mass passing through it, influencing efficiency and noise levels.

What is Bypass Ratio?

Bypass ratio is the measure of the amount of air a turbofan engine moves around the core compared to the air moving through the core itself. High-bypass turbofan engines have a large bypass ratio, meaning most air flows around the core, providing greater thrust efficiency and quieter operation, making them ideal for commercial airliners. Low-bypass turbofans have a smaller bypass ratio and generate more thrust through the core, offering higher performance suitable for military aircraft and supersonic speeds.

Overview of High-bypass Turbofan Engines

High-bypass turbofan engines feature a large fan that directs most airflow around the engine core, significantly improving fuel efficiency and reducing noise levels compared to low-bypass designs. These engines typically have bypass ratios greater than 5:1, making them ideal for commercial airliners requiring high thrust and long-range performance. The increased mass of air moved by the fan contributes to better thrust generation while maintaining lower specific fuel consumption, enhancing overall operational economy.

Overview of Low-bypass Turbofan Engines

Low-bypass turbofan engines feature a smaller fan diameter and lower bypass ratio compared to high-bypass turbofans, resulting in higher exhaust velocities and increased thrust suitable for military jets and supersonic aircraft. These engines prioritize performance and speed over fuel efficiency, producing greater specific thrust which enhances maneuverability and acceleration. Their compact design supports high operational altitudes and rapid throttle response, making them ideal for combat and high-performance aviation applications.

Efficiency and Fuel Consumption Comparison

High-bypass turbofan engines offer greater efficiency and lower fuel consumption due to their larger fan diameter, which moves more air with less fuel, making them ideal for commercial airliners on long-haul flights. Low-bypass turbofans, with smaller bypass ratios, consume more fuel as they produce higher exhaust velocities tailored for supersonic speeds and military applications. Your choice between these engines impacts operational cost and environmental footprint, with high-bypass models preferred for optimal fuel economy.

Noise Levels and Environmental Impact

High-bypass turbofan engines significantly reduce noise levels compared to low-bypass variants due to their larger fan diameter and greater air mass flow, which helps muffle engine noise. These engines also contribute to lower environmental impact by enhancing fuel efficiency and cutting carbon emissions, making them the preferred choice for commercial aviation aiming to meet stringent noise and pollution regulations. Understanding the differences in noise and environmental impact can help you choose or support aerospace technologies aligned with sustainable aviation goals.

Applications in Commercial vs Military Aviation

High-bypass turbofans dominate commercial aviation due to their superior fuel efficiency and reduced noise levels, making them ideal for long-haul passenger aircraft such as the Boeing 787 and Airbus A350. Low-bypass turbofans are preferred in military aviation, providing higher thrust-to-weight ratios and better performance at supersonic speeds, as seen in fighters like the F-22 Raptor and F-35 Lightning II. The distinct bypass ratios influence operational efficiency and mission profiles, with high-bypass engines optimized for endurance and low-bypass engines for agility and speed.

Performance Differences: Thrust and Speed

High-bypass turbofan engines generate greater thrust by moving a larger volume of air around the engine core, resulting in higher fuel efficiency and quieter operation, ideal for commercial airliners cruising at subsonic speeds. Low-bypass turbofans produce less bypass airflow but achieve higher exhaust velocities, offering increased thrust-to-weight ratios and better performance at supersonic speeds and military applications. The thrust in high-bypass engines is optimized for fuel-efficient, slower cruising, while low-bypass engines trade efficiency for speed and power, making them suitable for different flight regimes.

Maintenance and Operational Costs

High-bypass turbofan engines offer lower maintenance and operational costs due to their higher fuel efficiency and reduced wear on core components, leading to extended maintenance intervals. Low-bypass turbofan engines, while providing higher thrust-to-weight ratios, generally incur increased maintenance expenses from more frequent overhauls and higher fuel consumption. Airlines favor high-bypass turbofans for commercial operations to optimize lifecycle costs and improve overall operational efficiency.

Future Trends in Turbofan Technology

High-bypass turbofans dominate future aerospace propulsion trends due to their superior fuel efficiency and reduced emissions, aligning with increasing environmental regulations and sustainability goals. Ongoing advancements in materials science and aerodynamic design are enhancing bypass ratios, allowing for quieter and more cost-effective engines with improved thrust-to-weight performance. Your investment in aircraft equipped with these next-generation high-bypass turbofan engines can lead to significant operational savings and compliance with evolving aviation standards.

High-bypass vs Low-bypass Turbofan Infographic

libmatt.com

libmatt.com