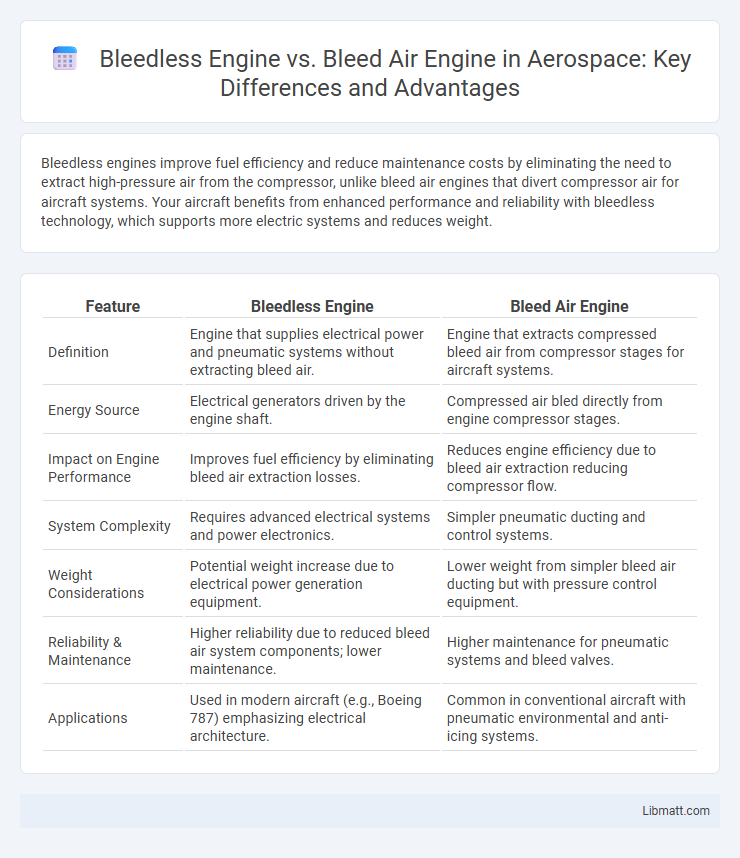

Bleedless engines improve fuel efficiency and reduce maintenance costs by eliminating the need to extract high-pressure air from the compressor, unlike bleed air engines that divert compressor air for aircraft systems. Your aircraft benefits from enhanced performance and reliability with bleedless technology, which supports more electric systems and reduces weight.

Table of Comparison

| Feature | Bleedless Engine | Bleed Air Engine |

|---|---|---|

| Definition | Engine that supplies electrical power and pneumatic systems without extracting bleed air. | Engine that extracts compressed bleed air from compressor stages for aircraft systems. |

| Energy Source | Electrical generators driven by the engine shaft. | Compressed air bled directly from engine compressor stages. |

| Impact on Engine Performance | Improves fuel efficiency by eliminating bleed air extraction losses. | Reduces engine efficiency due to bleed air extraction reducing compressor flow. |

| System Complexity | Requires advanced electrical systems and power electronics. | Simpler pneumatic ducting and control systems. |

| Weight Considerations | Potential weight increase due to electrical power generation equipment. | Lower weight from simpler bleed air ducting but with pressure control equipment. |

| Reliability & Maintenance | Higher reliability due to reduced bleed air system components; lower maintenance. | Higher maintenance for pneumatic systems and bleed valves. |

| Applications | Used in modern aircraft (e.g., Boeing 787) emphasizing electrical architecture. | Common in conventional aircraft with pneumatic environmental and anti-icing systems. |

Introduction to Aircraft Engine Bleed Systems

Aircraft engine bleed systems play a crucial role in regulating cabin pressurization, anti-icing, and environmental control by extracting high-pressure air from compressor stages. Bleedless engines, typically found in more modern aircraft like the Boeing 787, eliminate traditional bleed air extraction to improve fuel efficiency and reduce maintenance complexity by using electrically driven systems instead. Your understanding of these differences highlights advancements in aerospace engineering aimed at optimizing engine performance and reliability.

What is a Bleed Air Engine?

A bleed air engine extracts high-pressure air from the compressor stage of a jet engine to power aircraft systems such as air conditioning and anti-icing. This method can reduce overall engine efficiency due to the diversion of compressed air, impacting fuel consumption and performance. Understanding the differences between bleed air and bleedless engine designs helps optimize your aircraft's operational efficiency and maintenance needs.

What is a Bleedless Engine?

A bleedless engine is a type of aircraft propulsion system that does not extract compressed air from the engine's compressor stages to supply air for cabin pressurization and aircraft systems. Instead, it relies on electrical power generated by the engine-driven generators to operate environmental control systems, leading to improved fuel efficiency and reduced maintenance. This design contrasts with traditional bleed air engines, which divert high-pressure air from the compressor, potentially affecting engine performance and increasing thermal stresses.

Historical Evolution of Engine Bleed Technologies

Bleedless engines represent a significant advancement over traditional bleed air engines, stemming from the need to improve fuel efficiency and reduce maintenance complexity that characterized early jet engine designs. Historically, bleed air technology emerged in the mid-20th century, tapping compressor air to power aircraft systems, which, although reliable, reduced overall engine performance. Modern bleedless engines eliminate this air extraction by using electrically driven systems, thereby optimizing engine operation and improving your aircraft's overall efficiency and environmental footprint.

Key Differences Between Bleedless and Bleed Air Engines

Bleedless engines extract electrical power directly from the engine's shaft without diverting compressed air, improving fuel efficiency and reducing maintenance requirements compared to bleed air engines. Bleed air engines use high-pressure air bled from the compressor stage to power aircraft systems, which can reduce engine performance and increase complexity. The transition to bleedless technology enhances overall aircraft performance by minimizing performance losses and optimizing system integration.

Efficiency and Fuel Consumption Comparison

Bleedless engines improve efficiency by eliminating the use of compressed bleed air for aircraft systems, allowing more engine power to be directed towards thrust generation and reducing fuel consumption. Compared to bleed air engines, bleedless architectures lower operational costs through enhanced fuel economy and reduced maintenance requirements due to fewer bleed air-related components. Your aircraft can benefit from these advancements by achieving better overall performance and reduced environmental impact.

Impact on Aircraft Environmental Control Systems

Bleedless engines improve aircraft environmental control systems by supplying electrical power instead of using high-pressure bleed air, enhancing system efficiency and reducing fuel consumption. Traditional bleed air engines extract compressed air from the engine compressor stages to operate environmental control systems, leading to performance penalties and increased maintenance. The shift to bleedless technology enables precise control of cabin pressure and temperature while decreasing engine wear and emissions.

Maintenance and Reliability Factors

Bleedless engines offer simplified maintenance by eliminating complex bleed air extraction systems, resulting in fewer components prone to leaks and failures, which enhances overall reliability. In contrast, bleed air engines require regular inspections and maintenance of bleed valves, ducts, and seals to prevent air leaks and potential performance issues. Your maintenance costs and downtime can be significantly reduced with bleedless engines due to their streamlined architecture and improved reliability.

Industry Trends and Adoption of Bleedless Technology

Bleedless engine technology is rapidly gaining traction in the aerospace industry due to its potential for enhanced fuel efficiency, reduced maintenance costs, and lower environmental impact compared to traditional bleed air engines. Major manufacturers such as Pratt & Whitney and General Electric are investing heavily in bleedless designs, which integrate electrical systems to improve overall aircraft performance and reduce complexity. Airlines are increasingly adopting bleedless engines in next-generation aircraft models, aligning with global trends toward sustainability and operational efficiency.

Future Outlook: Next-Generation Aircraft Propulsion Systems

Bleedless engines represent the future of aircraft propulsion by improving fuel efficiency and reducing environmental impact through direct electric power systems, eliminating the need to extract bleed air from the engine compressor. This technology supports advanced aircraft designs, such as the Boeing 787 and Airbus A350, enabling more reliable and lightweight systems compared to traditional bleed air engines. Your choice in next-generation aircraft may benefit from these innovations, offering enhanced performance, reduced maintenance costs, and lower emissions for sustainable aviation progress.

bleedless engine vs bleed air engine Infographic

libmatt.com

libmatt.com