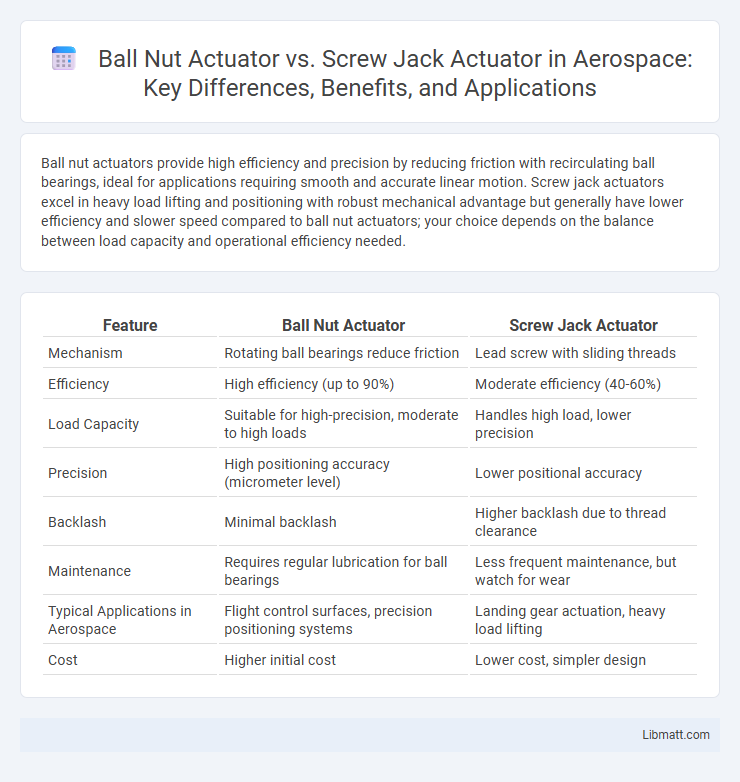

Ball nut actuators provide high efficiency and precision by reducing friction with recirculating ball bearings, ideal for applications requiring smooth and accurate linear motion. Screw jack actuators excel in heavy load lifting and positioning with robust mechanical advantage but generally have lower efficiency and slower speed compared to ball nut actuators; your choice depends on the balance between load capacity and operational efficiency needed.

Table of Comparison

| Feature | Ball Nut Actuator | Screw Jack Actuator |

|---|---|---|

| Mechanism | Rotating ball bearings reduce friction | Lead screw with sliding threads |

| Efficiency | High efficiency (up to 90%) | Moderate efficiency (40-60%) |

| Load Capacity | Suitable for high-precision, moderate to high loads | Handles high load, lower precision |

| Precision | High positioning accuracy (micrometer level) | Lower positional accuracy |

| Backlash | Minimal backlash | Higher backlash due to thread clearance |

| Maintenance | Requires regular lubrication for ball bearings | Less frequent maintenance, but watch for wear |

| Typical Applications in Aerospace | Flight control surfaces, precision positioning systems | Landing gear actuation, heavy load lifting |

| Cost | Higher initial cost | Lower cost, simpler design |

Overview: Ball Nut Actuator vs Screw Jack Actuator

Ball nut actuators utilize precision-ground balls and a nut mechanism to provide high efficiency and smooth linear motion, ideal for applications demanding high speed and accuracy. Screw jack actuators operate via a lead screw and nut system, offering robust load capacity and reliable performance in heavy-duty vertical and horizontal lifting tasks. While ball nut actuators excel in precision and reduced friction, screw jack actuators are preferred for their durability and ability to handle greater loads in industrial environments.

How Ball Nut Actuators Work

Ball nut actuators convert rotary motion into linear motion using recirculating ball bearings that reduce friction and improve efficiency. The ball bearings circulate within the nut and screw thread, enabling smooth movement and higher load capacity compared to traditional screw jack actuators. This design ensures precise positioning and longer service life in automated systems.

Working Principle of Screw Jack Actuators

Screw jack actuators operate by converting rotary motion into linear motion through a lead screw mechanism, where the turning of a screw thread drives a nut along its length to produce controlled lifting or lowering. This mechanical advantage allows precise handling of heavy loads with relatively low input force. Your choice between ball nut actuators and screw jack actuators depends on desired efficiency, load capacity, and operational smoothness.

Key Differences Between Ball Nut and Screw Jack Actuators

Ball nut actuators use recirculating ball bearings to reduce friction and increase efficiency, resulting in higher load capacity and faster linear motion. Screw jack actuators rely on a trapezoidal or acme threaded shaft, providing simplicity and durability but generally less efficiency and slower speeds. Your choice depends on the balance between precision, load requirements, and maintenance needs specific to your application.

Precision and Accuracy Comparison

Ball nut actuators offer higher precision and accuracy due to their reduced axial play and smoother linear motion, making them ideal for applications requiring exact positioning. In contrast, screw jack actuators tend to have more backlash and lower resolution, which can decrease their accuracy in fine adjustments. Your choice should consider the level of precision necessary for your project, as ball nut actuators typically deliver superior performance in meticulous movement control.

Load Capacity and Efficiency Analysis

Ball nut actuators offer higher efficiency due to reduced friction, enabling smoother motion and better energy transfer, making them ideal for applications requiring rapid, precise movements under moderate to high loads. Screw jack actuators excel in load capacity, supporting heavier weights with robust mechanical advantage, but they typically operate at lower efficiency because of increased friction and slower speed. Your choice should balance the need for load capacity and energy efficiency based on the specific demands of your application.

Maintenance and Lifespan Considerations

Ball nut actuators require minimal maintenance due to their preloaded ball bearings that reduce friction and wear, extending service intervals. Screw jack actuators demand regular lubrication and inspection to prevent thread wear and corrosion, impacting their operational lifespan. The longer lifespan of ball nut actuators makes them a cost-effective choice for applications involving frequent or continuous use.

Typical Applications for Ball Nut Actuators

Ball nut actuators are commonly used in applications requiring high precision and repeatability, such as CNC machines, robotic arms, and automation systems where accurate linear motion is critical. Their ability to handle heavy loads with minimal backlash makes them ideal for injection molding machines, packaging equipment, and valve actuators in industrial settings. If your project demands smooth, reliable motion control with compact design, ball nut actuators offer significant advantages over screw jack actuators.

Common Uses of Screw Jack Actuators

Screw jack actuators are commonly used in heavy-duty applications such as lifting, lowering, and positioning heavy machinery or structural components. Their robust design and high load capacity make them ideal for industrial automation, material handling, and construction projects. You can rely on screw jack actuators for reliable mechanical advantage in applications requiring precise linear motion and heavy load support.

Choosing the Right Actuator for Your Application

Ball nut actuators offer high efficiency and precision due to their rolling element design, making them ideal for applications requiring smooth, repetitive motion and high load capacity with minimal backlash. Screw jack actuators excel in heavy-duty lifting scenarios with robust construction and simplicity, providing reliable vertical load movement and manual override options for safety and control. Selecting the right actuator depends on factors such as load requirements, motion precision, installation environment, and maintenance considerations specific to your application.

ball nut actuator vs screw jack actuator Infographic

libmatt.com

libmatt.com