Truss structures distribute loads through interconnected triangular units, providing high strength and rigidity with minimal material use, ideal for bridges and towers. Monocoque designs rely on the external skin to support loads, offering lightweight efficiency and streamlined aesthetics common in automotive and aerospace engineering.

Table of Comparison

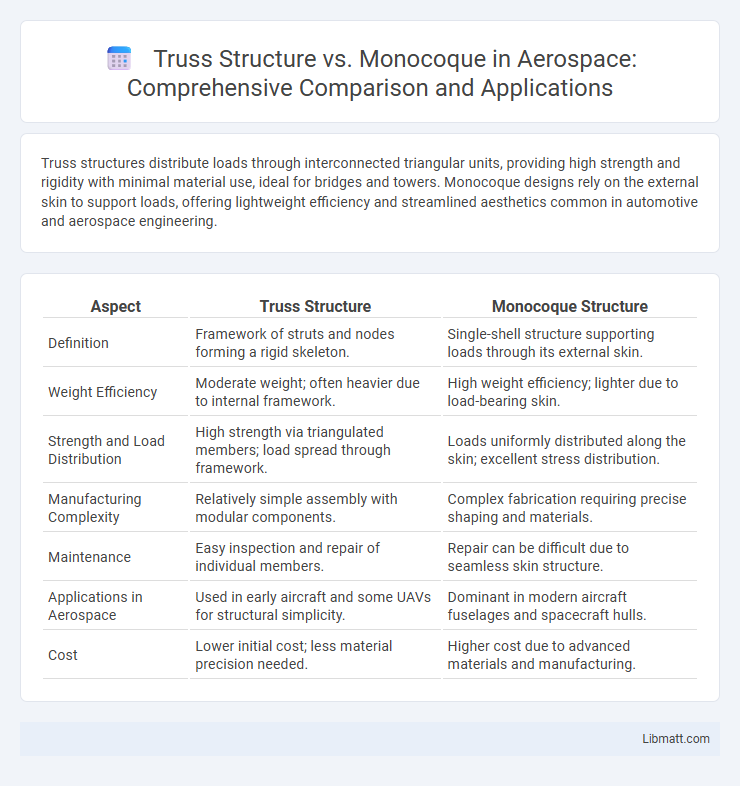

| Aspect | Truss Structure | Monocoque Structure |

|---|---|---|

| Definition | Framework of struts and nodes forming a rigid skeleton. | Single-shell structure supporting loads through its external skin. |

| Weight Efficiency | Moderate weight; often heavier due to internal framework. | High weight efficiency; lighter due to load-bearing skin. |

| Strength and Load Distribution | High strength via triangulated members; load spread through framework. | Loads uniformly distributed along the skin; excellent stress distribution. |

| Manufacturing Complexity | Relatively simple assembly with modular components. | Complex fabrication requiring precise shaping and materials. |

| Maintenance | Easy inspection and repair of individual members. | Repair can be difficult due to seamless skin structure. |

| Applications in Aerospace | Used in early aircraft and some UAVs for structural simplicity. | Dominant in modern aircraft fuselages and spacecraft hulls. |

| Cost | Lower initial cost; less material precision needed. | Higher cost due to advanced materials and manufacturing. |

Introduction to Structural Engineering Systems

Truss structures utilize interconnected triangular units to efficiently distribute loads and provide strong resistance to bending and twisting, making them ideal for bridges, towers, and roofs. Monocoque systems rely on a single shell or skin to bear structural stresses, offering lightweight durability commonly used in aerospace and automotive design. Your choice between these engineering systems depends on factors like load requirements, material efficiency, and application context.

Overview of Truss Structures

Truss structures consist of interconnected triangular units that efficiently distribute loads through tension and compression, enhancing stability and strength while minimizing material use. Commonly used in bridges, towers, and roof supports, trusses offer exceptional rigidity and can span large distances without excessive weight. Their geometric design enables easy customization and prefabrication, making them ideal for construction projects requiring durability and cost-effectiveness.

Overview of Monocoque Structures

Monocoque structures rely on the external skin to bear most of the stresses, eliminating the need for an internal frame, which results in lightweight and aerodynamic designs common in aerospace and automotive industries. These structures offer excellent strength-to-weight ratios by distributing loads across the surface, enhancing efficiency and performance in aircraft fuselages and racing car bodies. Compared to truss structures, monocoques provide smoother surfaces and reduced drag, but require advanced materials and precise manufacturing techniques to maintain structural integrity.

Key Differences Between Truss and Monocoque Designs

Truss structures rely on interconnected triangular units for strength and load distribution, offering high rigidity with minimal material use, while monocoque designs utilize the external skin to bear loads, providing a lightweight yet aerodynamic shape. Truss systems are easier to repair and modify, making them ideal for applications requiring strong frameworks, whereas monocoques excel in reducing weight and improving performance in automotive and aerospace industries. Understanding these key differences helps you choose the optimal design approach based on structural needs and efficiency goals.

Structural Efficiency and Weight Considerations

Truss structures offer high structural efficiency through a network of interconnected elements that distribute loads evenly, enabling lightweight construction without sacrificing strength. In contrast, monocoque designs rely on the external skin to bear stresses, which can reduce overall weight by eliminating internal frameworks but may require thicker materials to maintain rigidity. Your choice between the two should consider the specific balance you need between weight savings and load distribution efficiency for optimal performance.

Material Usage in Truss vs Monocoque

Truss structures use interconnected elements to efficiently distribute loads, typically requiring less material by optimizing the placement of steel or aluminum members. Monocoque designs integrate the skin and frame into a single shell, often demanding higher-quality materials like carbon fiber composites to achieve strength without additional weight. Material usage in truss structures is generally more economical for straightforward applications, while monocoque construction excels in weight reduction and aerodynamic performance through advanced material technology.

Typical Applications in Industry

Truss structures are commonly used in bridges, towers, and aircraft frameworks due to their high strength-to-weight ratio and efficient load distribution. Monocoque designs dominate the automotive and aerospace industries where aerodynamic shape and lightweight construction enhance performance and fuel efficiency. Your choice depends on whether structural rigidity or streamlined aesthetics and weight savings are the priority.

Manufacturing and Maintenance Factors

Truss structures are generally easier and more cost-effective to manufacture due to their assembly from standardized components, allowing for straightforward repairs and part replacements during maintenance. Monocoque designs, while offering superior aerodynamic efficiency and weight savings, require advanced manufacturing techniques such as composite layups or metal forming, which can increase production complexity and cost. Maintenance of monocoque structures often involves specialized skills and equipment to address damage, making repairs more time-consuming and expensive compared to the modular nature of truss frameworks.

Cost Implications of Each Structure Type

Truss structures typically offer lower initial manufacturing costs due to simpler fabrication and common materials such as steel or aluminum. Monocoque structures, while more expensive upfront, provide enhanced material efficiency and weight savings that can reduce long-term operational costs. Your choice between these architectures impacts both the immediate budgeting and lifecycle expenses of the project.

Choosing the Right Structure for Your Project

Choosing the right structure for your project depends on factors like weight, strength, and manufacturing complexity. Truss structures offer high strength-to-weight ratios and easier repairs, ideal for projects prioritizing durability and cost-efficiency. Monocoque designs provide lightweight, seamless aerodynamic advantages suitable for high-performance applications where structural efficiency is critical for Your success.

truss structure vs monocoque Infographic

libmatt.com

libmatt.com