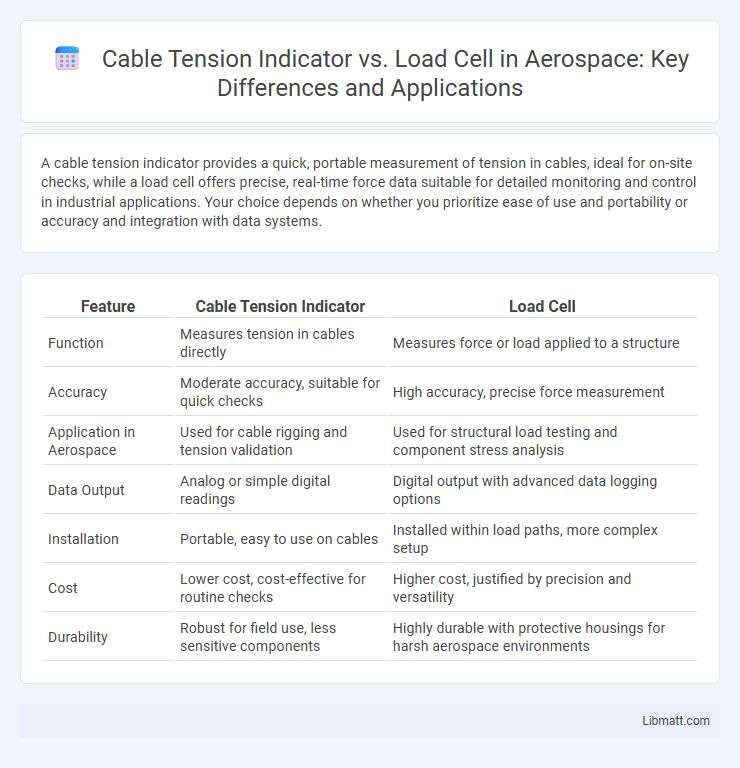

A cable tension indicator provides a quick, portable measurement of tension in cables, ideal for on-site checks, while a load cell offers precise, real-time force data suitable for detailed monitoring and control in industrial applications. Your choice depends on whether you prioritize ease of use and portability or accuracy and integration with data systems.

Table of Comparison

| Feature | Cable Tension Indicator | Load Cell |

|---|---|---|

| Function | Measures tension in cables directly | Measures force or load applied to a structure |

| Accuracy | Moderate accuracy, suitable for quick checks | High accuracy, precise force measurement |

| Application in Aerospace | Used for cable rigging and tension validation | Used for structural load testing and component stress analysis |

| Data Output | Analog or simple digital readings | Digital output with advanced data logging options |

| Installation | Portable, easy to use on cables | Installed within load paths, more complex setup |

| Cost | Lower cost, cost-effective for routine checks | Higher cost, justified by precision and versatility |

| Durability | Robust for field use, less sensitive components | Highly durable with protective housings for harsh aerospace environments |

Introduction: Cable Tension Indicators vs Load Cells

Cable tension indicators measure the tension in cables using visual or mechanical means, offering quick and cost-effective assessments critical for construction, suspension bridges, and rigging applications. Load cells provide precise electronic measurements by converting force into an electrical signal, essential for detailed monitoring and data logging in industries such as aerospace, manufacturing, and structural health monitoring. Compared to load cells, cable tension indicators generally have lower accuracy but are preferred for their simplicity and portability in field inspections.

Understanding Cable Tension Indicators

Cable tension indicators provide a straightforward, cost-effective solution for measuring tension by visually displaying the force applied to a cable, ideal for quick assessments and routine inspections. Unlike load cells, which offer precise digital measurements with high accuracy and the ability to integrate with monitoring systems, cable tension indicators prioritize ease of use and immediate feedback without complex setup. Your choice depends on whether you need real-time data logging and detailed analysis from load cells or rapid, on-site tension checks using cable tension indicators.

What is a Load Cell?

A load cell is an advanced sensor designed to measure force or weight with high precision by converting mechanical load into an electrical signal. Unlike a cable tension indicator, which provides a basic estimate of tension, a load cell offers accurate, real-time data essential for critical applications like structural monitoring and industrial weighing. Your choice of equipment impacts measurement accuracy, making load cells the preferred option for precise and reliable tension analysis.

Key Differences Between Cable Tension Indicators and Load Cells

Cable tension indicators provide direct measurement of tension in cables using mechanical or digital gauges, often offering quick, on-site readings without complex setup. Load cells measure force with high precision by converting mechanical force into electrical signals, making them ideal for detailed, real-time monitoring and integration with data systems. Key differences include accuracy, application complexity, and the method of force measurement--cable tension indicators are generally simpler and portable, while load cells deliver more precise and continuous data suitable for industrial automation.

Applications of Cable Tension Indicators

Cable tension indicators are extensively used in construction, bridge maintenance, and elevator installations to ensure optimal cable tension and structural integrity. These devices provide quick, reliable measurements for on-site adjustments, preventing cable failure and enhancing safety during critical load applications. Unlike load cells, cable tension indicators offer a cost-effective solution for real-time tension monitoring without requiring complex instrumentation.

Applications of Load Cells

Load cells are widely applied in industrial weighing systems, material testing machines, and structural health monitoring due to their high accuracy in measuring force or load. Unlike cable tension indicators that primarily assess tension in cables or wires, load cells convert mechanical force into an electrical signal for precise measurement, crucial in sectors like manufacturing, aerospace, and construction. Your choice of a load cell enables enhanced control and safety in processes requiring accurate load monitoring and data-driven decision-making.

Accuracy and Reliability Comparison

Load cells offer superior accuracy and reliability by directly measuring force with high precision sensors, minimizing errors caused by environmental factors or cable dynamics. Cable tension indicators provide quick, approximate measurements but are more susceptible to inaccuracies due to cable vibration and operator variability. For critical applications requiring precise load monitoring, load cells are the preferred choice due to their consistent and repeatable performance.

Installation and Maintenance Requirements

Cable tension indicators require minimal installation as they clamp directly onto the cable, providing quick, on-the-spot tension readings without complex setup. Load cells demand more extensive installation, involving precise mounting and integration into the system for accurate load measurement, which may require specialized tools and calibration. Your choice depends on whether ease of installation and low maintenance is prioritized or if precise, continuous load monitoring is essential.

Cost Considerations

Cable tension indicators generally offer a lower-cost solution compared to load cells, making them suitable for basic tension measurement needs without extensive accuracy requirements. Load cells, while more expensive due to advanced technology and higher precision, provide detailed, real-time data critical for applications demanding stringent load monitoring. Budget constraints often guide the choice between economical cable tension indicators and the investment in load cells' enhanced performance and durability.

Choosing the Right Solution for Your Needs

Selecting the right solution for your needs depends on the specific application and measurement accuracy required. Cable tension indicators provide a straightforward, cost-effective method for quick tension assessments, ideal for routine maintenance and field inspections. Load cells offer higher precision and data integration capabilities, making them suitable for detailed analysis and automated systems where accuracy is critical.

cable tension indicator vs load cell Infographic

libmatt.com

libmatt.com