COTS aerospace parts offer cost-effective, ready-made solutions that reduce lead times and simplify supply chain management compared to custom aerospace parts, which provide tailored designs optimized for specific performance requirements and regulatory compliance. Choosing between COTS and custom parts depends on your project's complexity, budget constraints, and the need for specialized functionality.

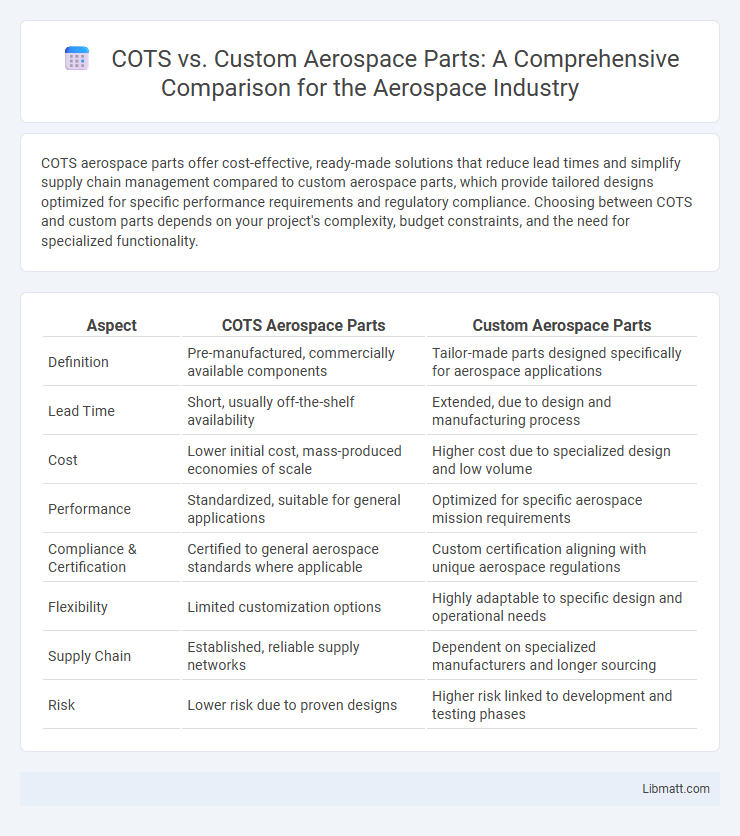

Table of Comparison

| Aspect | COTS Aerospace Parts | Custom Aerospace Parts |

|---|---|---|

| Definition | Pre-manufactured, commercially available components | Tailor-made parts designed specifically for aerospace applications |

| Lead Time | Short, usually off-the-shelf availability | Extended, due to design and manufacturing process |

| Cost | Lower initial cost, mass-produced economies of scale | Higher cost due to specialized design and low volume |

| Performance | Standardized, suitable for general applications | Optimized for specific aerospace mission requirements |

| Compliance & Certification | Certified to general aerospace standards where applicable | Custom certification aligning with unique aerospace regulations |

| Flexibility | Limited customization options | Highly adaptable to specific design and operational needs |

| Supply Chain | Established, reliable supply networks | Dependent on specialized manufacturers and longer sourcing |

| Risk | Lower risk due to proven designs | Higher risk linked to development and testing phases |

Introduction to COTS and Custom Aerospace Parts

COTS (Commercial Off The Shelf) aerospace parts are pre-manufactured components readily available for purchase, offering cost-efficiency and shorter lead times compared to custom aerospace parts, which are specifically engineered to meet unique design and performance requirements. Your choice between COTS and custom parts depends on factors such as aircraft mission profiles, regulatory compliance, and integration complexity. Custom aerospace parts provide tailored solutions with enhanced reliability and optimized performance, whereas COTS parts benefit from established industry standards and mass production economies.

Key Definitions: COTS vs Custom Solutions

COTS (Commercial Off The Shelf) aerospace parts refer to standardized, mass-produced components readily available for purchase, offering cost efficiency and faster procurement. Custom aerospace parts are specifically designed and manufactured to meet unique technical specifications and performance requirements, ensuring optimal integration and reliability for specialized applications. The decision between COTS and custom solutions hinges on balancing factors like lead time, cost, certification needs, and mission-critical performance.

Regulatory Standards and Compliance

COTS aerospace parts must meet general industry standards such as AS9100 and FAA regulations for airworthiness but often lack the rigorous, application-specific certifications required for critical flight components. Custom aerospace parts are designed and manufactured to comply with stringent regulatory standards, including EASA and DO-178C, ensuring full traceability and certification for mission-critical applications. Compliance with these regulations directly impacts safety, reliability, and certification processes within aerospace manufacturing and maintenance.

Cost Analysis: Initial Investment & Lifecycle Expenses

COTS aerospace parts offer lower initial investment due to mass production and standardized specifications, reducing upfront procurement costs. Custom aerospace components involve higher initial expenses from specialized design, testing, and certification tailored to unique requirements. Lifecycle expenses for COTS parts are generally more predictable and lower, benefiting from established maintenance protocols, while custom parts may incur increased costs over time related to specialized repairs, updates, and limited vendor support.

Lead Times and Availability

COTS aerospace parts offer significantly shorter lead times due to their mass production and wide availability from multiple suppliers, making them ideal for urgent project needs. Custom aerospace parts, however, require longer lead times because of specialized design, engineering, and manufacturing processes tailored to specific requirements. You must balance availability and speed against the unique performance demands of your aerospace application when choosing between COTS and custom components.

Performance and Reliability Considerations

COTS aerospace parts offer standardized performance and cost efficiency but may lack precise customization needed for specific mission-critical applications, impacting reliability in extreme conditions. Custom aerospace parts are designed to meet exact operational requirements, enhancing performance and reliability through tailored materials and engineering, albeit with higher development costs and longer lead times. Balancing performance demands and reliability standards is crucial in selecting between COTS and custom parts for aerospace systems.

Integration Challenges and Compatibility

COTS aerospace parts offer faster procurement but often face integration challenges due to limited customization options and variable compatibility with existing systems. Custom aerospace parts are designed specifically for unique aircraft requirements, ensuring higher compatibility and streamlined integration within complex avionics or mechanical systems. Evaluating system architecture and performing rigorous compatibility testing are critical steps when deciding between COTS and custom solutions to minimize integration risks.

Maintenance, Support, and Upgrades

COTS aerospace parts offer streamlined maintenance and readily available support due to standardized designs and widespread industry use, reducing downtime and costs. Custom aerospace components require specialized maintenance expertise and proprietary support, often increasing lead times and expense but allowing tailored upgrades to meet specific mission requirements. Upgrades for COTS parts are typically driven by vendor roadmaps, while custom parts enable bespoke enhancements aligned with unique operational needs.

Case Studies: Successful Applications in Aerospace

Case studies reveal COTS components like Avionics Standard Modules have improved aerospace system reliability and reduced production costs in commercial aircraft like Boeing 787. Custom aerospace parts, exemplified by SpaceX's proprietary rocket engine components, enable tailored performance for unique mission profiles, enhancing overall vehicle efficiency. Both COTS and custom parts contribute significantly to aerospace advancements, depending on application-specific demands and cost-benefit analyses.

Decision-Making Factors for Aerospace Engineers

Aerospace engineers weigh factors such as cost, lead time, and reliability when deciding between COTS and custom aerospace parts. COTS components offer quicker availability and lower initial costs but may lack tailored specifications essential for mission-critical applications. Custom parts provide optimized performance and compliance with stringent aerospace standards, though they involve higher development expenses and longer production cycles.

COTS (Commercial Off The Shelf) vs Custom Aerospace Parts Infographic

libmatt.com

libmatt.com