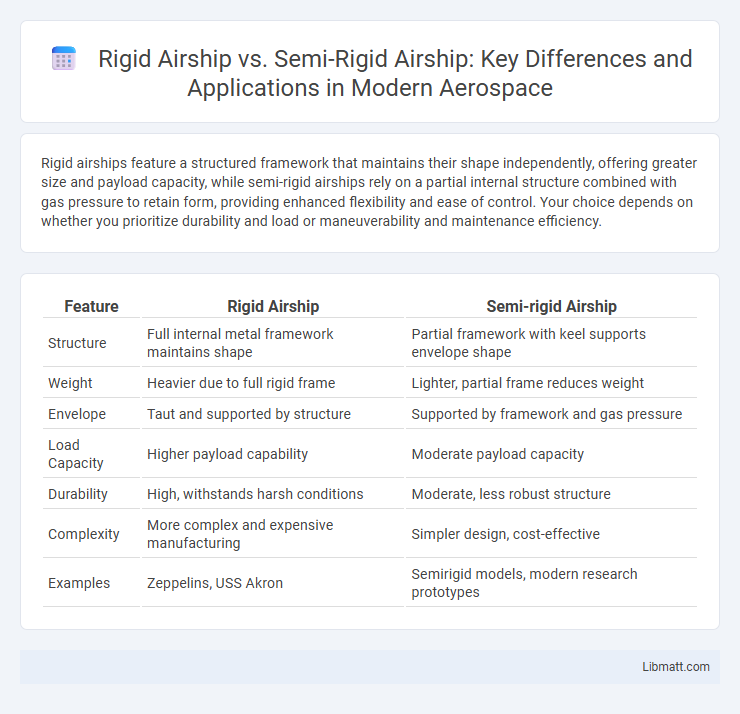

Rigid airships feature a structured framework that maintains their shape independently, offering greater size and payload capacity, while semi-rigid airships rely on a partial internal structure combined with gas pressure to retain form, providing enhanced flexibility and ease of control. Your choice depends on whether you prioritize durability and load or maneuverability and maintenance efficiency.

Table of Comparison

| Feature | Rigid Airship | Semi-rigid Airship |

|---|---|---|

| Structure | Full internal metal framework maintains shape | Partial framework with keel supports envelope shape |

| Weight | Heavier due to full rigid frame | Lighter, partial frame reduces weight |

| Envelope | Taut and supported by structure | Supported by framework and gas pressure |

| Load Capacity | Higher payload capability | Moderate payload capacity |

| Durability | High, withstands harsh conditions | Moderate, less robust structure |

| Complexity | More complex and expensive manufacturing | Simpler design, cost-effective |

| Examples | Zeppelins, USS Akron | Semirigid models, modern research prototypes |

Introduction to Airships: Rigid vs Semi-rigid

Rigid airships feature a framework made from lightweight materials such as aluminum or duralumin, providing a fixed structure that maintains the shape of the airship independently of the lifting gas. In contrast, semi-rigid airships combine a partial internal frame with an inflatable envelope, relying on the balance between internal gas pressure and structural support to maintain form and stability. Understanding these structural differences helps you appreciate the varying design principles, operational capabilities, and historical applications of rigid and semi-rigid airships.

Structural Design Differences

Rigid airships feature a solid framework made of lightweight materials such as aluminum or duralumin that maintains the shape of the envelope independently of internal gas pressure, allowing for larger size and multiple internal gas cells. Semi-rigid airships combine a partial rigid structure, typically a keel or lower frame, with a flexible envelope that relies on internal gas pressure to maintain shape, providing a balance between structural support and weight savings. The rigid framework supports structural loads and equipment, whereas semi-rigid designs reduce complexity by using the gas pressure for shape, resulting in different operational capabilities and maintenance requirements.

Materials and Construction Techniques

Rigid airships utilize a fixed internal framework made of lightweight materials such as duralumin, providing a solid skeleton that maintains shape regardless of internal gas pressure. Semi-rigid airships combine a partial internal structure with a flexible outer envelope, often constructed from reinforced fabrics like polyester or nylon coated with materials such as polyurethane for durability and gas retention. Your choice between these types depends on the desired balance of structural integrity, weight, and operational flexibility.

Historical Development and Usage

Rigid airships, pioneered by Count Ferdinand von Zeppelin in the early 20th century, featured a solid internal framework that allowed for massive sizes and longer flights, playing crucial roles in World War I reconnaissance and transatlantic travel. Semi-rigid airships, developed later, combined a partial internal structure with flexible envelopes, offering improved maneuverability and reduced weight while still maintaining structural integrity, making them popular for passenger transport and advertising in the mid-1900s. If your interest lies in aeronautical history, understanding these distinctions highlights the evolution of lighter-than-air technology and its impact on military and commercial aviation.

Aerodynamic Performance Comparison

Rigid airships maintain a fixed internal framework that provides consistent aerodynamic stability, resulting in smoother airflow and more efficient lift generation during flight. Semi-rigid airships rely on a partial internal structure combined with gas pressure, which can cause slight deformation under load, potentially increasing drag and reducing aerodynamic efficiency. Your choice between these types affects performance, with rigid airships generally offering superior aerodynamic characteristics for stable, high-speed operations.

Payload Capacity and Cargo Handling

Rigid airships offer higher payload capacity due to their strong internal framework that supports a larger volume of lifting gas and heavier cargo, making them ideal for transporting substantial loads. Semi-rigid airships, featuring a partial framework combined with flexible gas envelopes, provide moderate payload capacities but allow for more adaptable cargo handling and easier structural maintenance. Your choice depends on whether maximizing payload capacity or optimizing cargo handling versatility is the priority.

Safety Features and Risks

Rigid airships feature a strong internal framework that maintains their shape, enhancing structural integrity and reducing the risk of collapse during flight, whereas semi-rigid airships rely on a partial frame combined with pressure to maintain form, which can present vulnerabilities under certain stress conditions. Both types incorporate safety mechanisms such as multiple gas cells to prevent total deflation and advanced ballast systems for stability, but rigid airships generally offer higher resistance to damage from turbulence and weather due to their robust construction. However, rigid airships are more complex and heavier, potentially increasing the risk during emergency landings, while semi-rigid airships, being lighter, provide more maneuverability but may be more susceptible to structural failure under extreme conditions.

Operational Costs and Maintenance

Rigid airships incur higher operational costs due to their complex internal framework requiring extensive inspections and maintenance to ensure structural integrity. Semi-rigid airships benefit from simpler designs with a partial internal frame, leading to reduced maintenance efforts and lower operational expenses. Both types demand regular gas replenishment, but rigid airships' structural components increase overall upkeep costs compared to semi-rigid models.

Modern Applications and Innovations

Rigid airships maintain an internal framework that supports their shape, enabling larger payload capacities and enhanced stability for applications such as surveillance, cargo transport, and luxury tourism. Semi-rigid airships combine a partial internal structure with pressure-stabilized envelopes, offering improved maneuverability and cost-efficiency, making them ideal for environmental monitoring, advertising, and rapid deployment scenarios. Recent innovations include advanced composite materials and hybrid propulsion systems, which increase fuel efficiency and operational range for both airship types in modern aerospace industries.

Future Prospects in Airship Technology

Rigid airships feature a strong frame that maintains their shape independently, offering increased payload capacity and structural resilience, which supports long-range commercial and military applications. Semi-rigid airships combine a partial frame with internal gas pressure for shape retention, ensuring lighter weight and greater flexibility, ideal for cargo transport and surveillance missions in evolving markets. Emerging advances in lightweight materials, electrification, and autonomous navigation are driving innovation in both airship types, enhancing efficiency and expanding their roles in sustainable aviation and remote area connectivity.

Rigid Airship vs Semi-rigid Airship Infographic

libmatt.com

libmatt.com