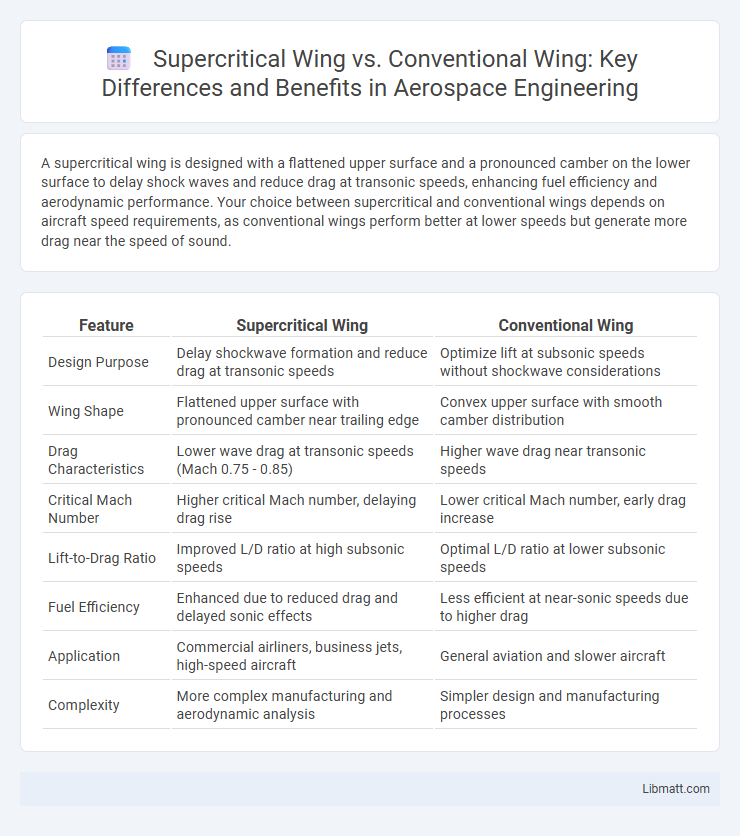

A supercritical wing is designed with a flattened upper surface and a pronounced camber on the lower surface to delay shock waves and reduce drag at transonic speeds, enhancing fuel efficiency and aerodynamic performance. Your choice between supercritical and conventional wings depends on aircraft speed requirements, as conventional wings perform better at lower speeds but generate more drag near the speed of sound.

Table of Comparison

| Feature | Supercritical Wing | Conventional Wing |

|---|---|---|

| Design Purpose | Delay shockwave formation and reduce drag at transonic speeds | Optimize lift at subsonic speeds without shockwave considerations |

| Wing Shape | Flattened upper surface with pronounced camber near trailing edge | Convex upper surface with smooth camber distribution |

| Drag Characteristics | Lower wave drag at transonic speeds (Mach 0.75 - 0.85) | Higher wave drag near transonic speeds |

| Critical Mach Number | Higher critical Mach number, delaying drag rise | Lower critical Mach number, early drag increase |

| Lift-to-Drag Ratio | Improved L/D ratio at high subsonic speeds | Optimal L/D ratio at lower subsonic speeds |

| Fuel Efficiency | Enhanced due to reduced drag and delayed sonic effects | Less efficient at near-sonic speeds due to higher drag |

| Application | Commercial airliners, business jets, high-speed aircraft | General aviation and slower aircraft |

| Complexity | More complex manufacturing and aerodynamic analysis | Simpler design and manufacturing processes |

Introduction to Wing Design Concepts

Supercritical wings feature a flattened upper surface and a pronounced aft camber, designed to delay shockwave formation and reduce drag at transonic speeds, enhancing fuel efficiency and cruise performance. Conventional wings typically have a more curved upper surface with early shockwave onset, resulting in higher drag and less favorable performance near the speed of sound. Advanced computational fluid dynamics and wind tunnel testing have proven supercritical wings optimize pressure distribution, improving lift-to-drag ratio compared to traditional airfoil sections.

What is a Supercritical Wing?

A supercritical wing features a flattened upper surface and a highly cambered lower surface designed to delay shockwave formation and reduce drag at transonic speeds, unlike conventional wings with more curved upper surfaces. This advanced aerodynamic design enhances fuel efficiency and improves cruise performance, especially for high-speed aircraft. Your aircraft benefits from smoother airflow and increased lift-to-drag ratio, making supercritical wings ideal for commercial jets and business planes.

Understanding Conventional Wing Characteristics

Conventional wings typically feature a rounded leading edge and a relatively thicker airfoil, generating smooth airflow at lower speeds but suffering from increased drag as speed approaches transonic ranges. These wings produce significant lift through attached turbulent boundary layers, which can lead to early shock wave formation and boundary layer separation near the critical Mach number. Understanding the stall behavior and drag rise characteristics of conventional wings is essential for optimizing aircraft performance in subsonic regimes.

Key Aerodynamic Differences

Supercritical wings feature a flattened upper surface and a pronounced aft camber, designed to delay shock wave formation and reduce wave drag at transonic speeds compared to conventional wings with rounded leading edges and higher camber. The critical Mach number of supercritical wings is significantly higher, allowing for improved fuel efficiency and cruise performance by minimizing drag rise near Mach 0.8 to 0.9. Conventional wings generate stronger shock waves resulting in increased drag and boundary layer separation, whereas supercritical designs maintain smoother airflow, enhancing lift-to-drag ratios at high subsonic speeds.

Performance at High Subsonic Speeds

Supercritical wings exhibit superior performance at high subsonic speeds by delaying shockwave formation and reducing drag compared to conventional wings, which experience increased wave drag near the transonic regime. The flattened upper surface and aft-loaded pressure distribution of supercritical airfoils enhance lift-to-drag ratios and improve fuel efficiency during cruise. Conventional wings, designed primarily for low-speed performance, suffer from early shock-induced boundary layer separation, limiting their effectiveness at speeds approaching Mach 0.8 to 0.9.

Fuel Efficiency Comparison

Supercritical wings enhance fuel efficiency by reducing drag at transonic speeds, which leads to lower fuel consumption compared to conventional wings. Their unique airfoil design delays shock wave formation, improving lift-to-drag ratios and enabling aircraft to cruise with optimal aerodynamic performance. Your choice of wing design directly impacts operational costs and environmental sustainability through improved fuel economy.

Structural Design and Material Considerations

Supercritical wings feature a thicker airfoil and a flattened upper surface to delay shockwave formation and reduce drag, requiring advanced composite materials like carbon fiber for their structural integrity and weight efficiency. Conventional wings rely on thinner profiles and aluminum alloys, prioritizing simplicity and cost-effectiveness but facing limitations in high-speed aerodynamic performance. The structural design of supercritical wings emphasizes load distribution over larger wing chords, influencing material selection to balance stiffness, fatigue resistance, and flexibility, critical for modern jet aircraft at transonic speeds.

Advantages and Disadvantages

Supercritical wings offer improved aerodynamic efficiency by delaying shockwave formation at transonic speeds, resulting in reduced drag and better fuel economy compared to conventional wings. However, supercritical wings have a more complex design and manufacturing process, leading to higher production costs and potential maintenance challenges. Your choice depends on whether performance gains outweigh these economic and operational considerations.

Applications in Modern Aircraft

Supercritical wings enhance fuel efficiency and reduce drag by delaying shock waves at transonic speeds, making them ideal for modern commercial airliners such as the Boeing 747 and Airbus A320 family. Conventional wings remain prevalent in general aviation and smaller aircraft where lower speeds and simpler designs prioritize cost and maneuverability. Your choice between these wing types directly impacts performance, fuel consumption, and operational costs in current aerospace applications.

Future Trends in Wing Technology

Supercritical wings, with their advanced curvature and reduced drag at transonic speeds, are shaping future trends in aerodynamics by enhancing fuel efficiency and extending aircraft range compared to conventional wings. Innovations like adaptive wing structures and smart materials are expected to integrate with supercritical designs, optimizing aerodynamic performance under varying flight conditions. Your aircraft can benefit from these cutting-edge technologies by adopting supercritical wings that pave the way for greener, quieter, and more efficient air travel.

Supercritical wing vs Conventional wing Infographic

libmatt.com

libmatt.com