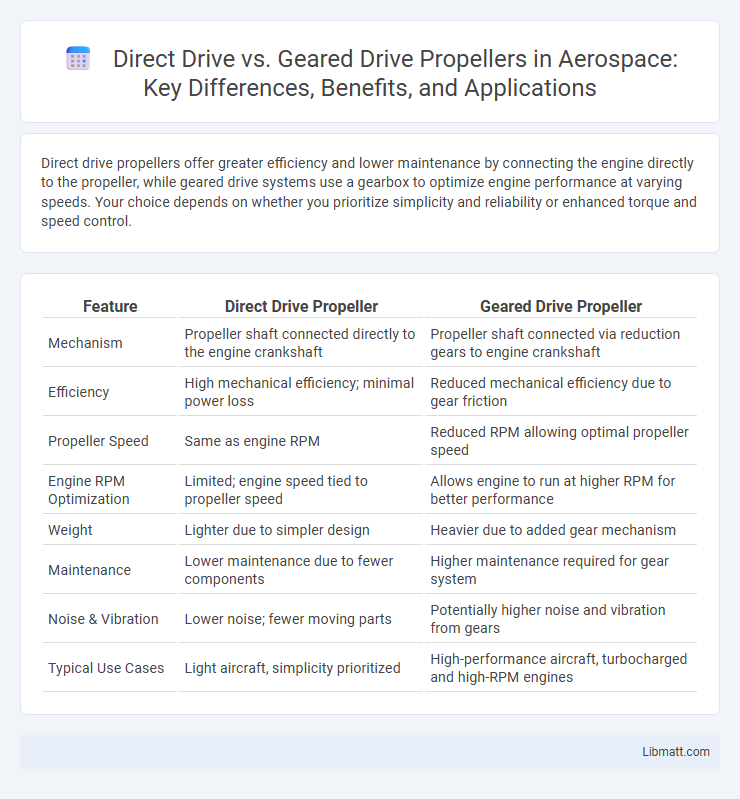

Direct drive propellers offer greater efficiency and lower maintenance by connecting the engine directly to the propeller, while geared drive systems use a gearbox to optimize engine performance at varying speeds. Your choice depends on whether you prioritize simplicity and reliability or enhanced torque and speed control.

Table of Comparison

| Feature | Direct Drive Propeller | Geared Drive Propeller |

|---|---|---|

| Mechanism | Propeller shaft connected directly to the engine crankshaft | Propeller shaft connected via reduction gears to engine crankshaft |

| Efficiency | High mechanical efficiency; minimal power loss | Reduced mechanical efficiency due to gear friction |

| Propeller Speed | Same as engine RPM | Reduced RPM allowing optimal propeller speed |

| Engine RPM Optimization | Limited; engine speed tied to propeller speed | Allows engine to run at higher RPM for better performance |

| Weight | Lighter due to simpler design | Heavier due to added gear mechanism |

| Maintenance | Lower maintenance due to fewer components | Higher maintenance required for gear system |

| Noise & Vibration | Lower noise; fewer moving parts | Potentially higher noise and vibration from gears |

| Typical Use Cases | Light aircraft, simplicity prioritized | High-performance aircraft, turbocharged and high-RPM engines |

Introduction to Propeller Drive Systems

Propeller drive systems in marine vessels primarily consist of direct drive and geared drive configurations, each influencing performance and efficiency. Direct drive systems connect the engine directly to the propeller shaft, offering simplicity and reduced maintenance, ideal for lower power applications and higher rotational speeds. Geared drive systems use reduction gears to optimize propeller RPM relative to engine speed, enhancing fuel efficiency and torque for larger vessels or those requiring precise speed control.

What is Direct Drive?

Direct drive refers to a propulsion system where the engine or motor is connected directly to the propeller shaft, eliminating the need for gears or transmission components. This setup improves efficiency by reducing mechanical losses and simplifying maintenance, making it ideal for applications requiring reliable, smooth power delivery. Your choice of direct drive can enhance performance in boats, generators, and industrial machinery by providing consistent torque and lower noise levels.

What is Geared Drive?

Geared drive is a propulsion system where the engine's output is transmitted to the propeller through a set of gears, allowing the engine to operate at an optimal speed while the propeller spins at a different, more efficient speed. This arrangement improves fuel efficiency, reduces engine wear, and enhances overall performance, especially in marine and aviation applications. Understanding geared drive helps you choose a propulsion setup that balances power delivery with mechanical durability.

Key Differences Between Direct Drive and Geared Drive

Direct drive systems connect the motor shaft directly to the propeller, offering higher efficiency and reduced maintenance due to fewer moving parts. Geared drive systems use a gear reduction mechanism to lower the propeller speed while allowing the engine to run at optimal RPM, enhancing torque and improving fuel efficiency in varying load conditions. Your choice depends on whether you prioritize simplicity and efficiency (direct drive) or torque and adaptability (geared drive) for your marine propulsion needs.

Advantages of Direct Drive Propellers

Direct drive propellers offer enhanced mechanical efficiency by eliminating the need for a gearbox, resulting in reduced power loss and improved fuel economy. They provide smoother operation with fewer moving parts, which lowers maintenance requirements and increases system reliability. Direct drive systems also tend to be lighter and more compact, contributing to overall vessel performance and handling.

Advantages of Geared Drive Propellers

Geared drive propellers offer enhanced fuel efficiency by allowing the engine to operate at optimal RPM while the propeller turns at a slower, more efficient speed. This reduction in propeller speed minimizes noise and vibration, contributing to a smoother and quieter vessel operation. The gearing system also permits the use of larger, more effective propellers that improve thrust and overall performance in various marine conditions.

Performance Comparison: Efficiency and Power

Direct drive propellers offer higher efficiency at lower RPMs by eliminating gear losses, resulting in smoother power transfer and improved fuel economy. Geared drive systems allow the engine to run at optimal higher RPMs while reducing propeller speed, which can increase overall power output and reduce vibration but may introduce some mechanical inefficiencies. Your choice between direct drive and geared drive depends on balancing efficiency needs with desired power performance for specific maritime applications.

Maintenance and Durability Factors

Direct drive systems require less maintenance due to fewer moving parts and lack of gears, enhancing overall durability and reducing long-term repair costs. Geared drive propellers experience higher wear and tear on gears, necessitating regular inspections and lubrication to prevent failure and extend lifespan. Your choice between these propulsion types should consider maintenance frequency and expected durability based on operational demands and vessel usage.

Applications: When to Choose Direct vs Geared Drive

Direct drive propulsion suits electric vehicles requiring high efficiency and reduced maintenance, ideal for applications such as electric cars, scooters, and industrial machinery with consistent speed demands. Geared drive systems excel in scenarios demanding high torque and variable speeds, making them preferred for heavy-duty equipment, off-road vehicles, and marine propeller systems. Choosing direct drive is optimal for quieter, smoother operation and increased reliability, while geared drives offer versatility and power amplification in demanding load conditions.

Conclusion: Selecting the Right Propeller Drive System

Choosing the right propeller drive system depends on your vessel's performance requirements and maintenance preferences. Direct drive offers simplicity, higher efficiency, and lower maintenance, making it ideal for smaller boats or those prioritizing reliability. Geared drives provide better torque and flexibility for larger vessels or demanding conditions, so assess your operational needs to determine the best fit for your watercraft.

Direct drive vs Geared drive (propeller) Infographic

libmatt.com

libmatt.com