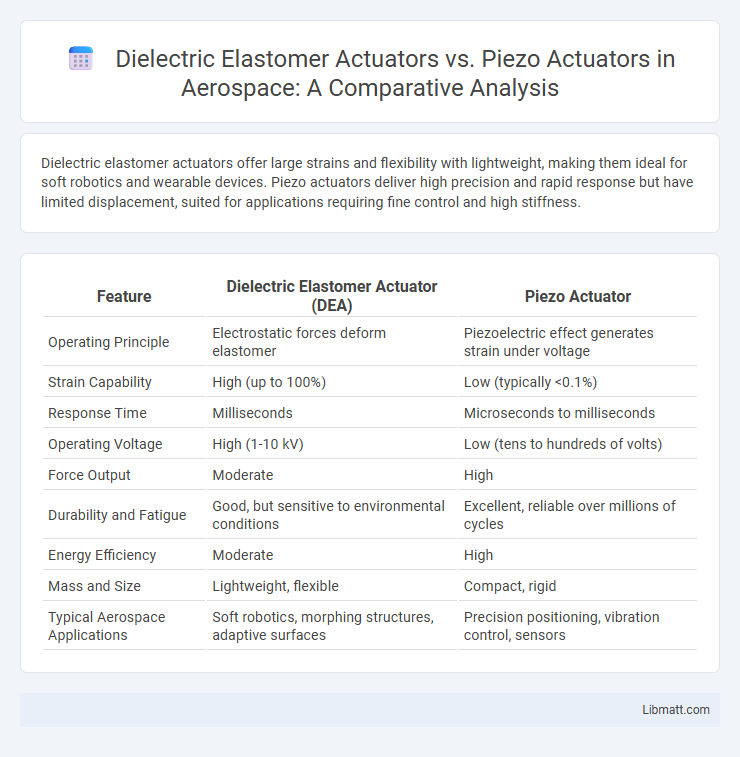

Dielectric elastomer actuators offer large strains and flexibility with lightweight, making them ideal for soft robotics and wearable devices. Piezo actuators deliver high precision and rapid response but have limited displacement, suited for applications requiring fine control and high stiffness.

Table of Comparison

| Feature | Dielectric Elastomer Actuator (DEA) | Piezo Actuator |

|---|---|---|

| Operating Principle | Electrostatic forces deform elastomer | Piezoelectric effect generates strain under voltage |

| Strain Capability | High (up to 100%) | Low (typically <0.1%) |

| Response Time | Milliseconds | Microseconds to milliseconds |

| Operating Voltage | High (1-10 kV) | Low (tens to hundreds of volts) |

| Force Output | Moderate | High |

| Durability and Fatigue | Good, but sensitive to environmental conditions | Excellent, reliable over millions of cycles |

| Energy Efficiency | Moderate | High |

| Mass and Size | Lightweight, flexible | Compact, rigid |

| Typical Aerospace Applications | Soft robotics, morphing structures, adaptive surfaces | Precision positioning, vibration control, sensors |

Introduction to Dielectric Elastomer and Piezo Actuators

Dielectric elastomer actuators (DEAs) are soft, flexible materials that deform in response to an electric field, offering large strain and lightweight performance ideal for soft robotics and adaptive structures. Piezoelectric actuators utilize crystalline materials that generate mechanical displacement under an applied voltage, providing high precision and fast response suitable for micro-positioning and vibration control. Key differences include DEA's low modulus and large actuation strain versus piezo actuators' high stiffness and nanometer-scale displacement accuracy.

Working Principles: Dielectric Elastomer vs. Piezo Actuators

Dielectric elastomer actuators operate by applying an electric field that compresses or stretches a soft elastomer film, causing large, flexible deformations due to electrostatic forces. Piezo actuators rely on the piezoelectric effect, where an applied voltage induces precise mechanical strain in a crystalline material, enabling high-resolution, fast response movements. Your choice between these actuators depends on the required displacement range and flexibility versus precision and stiffness in your application.

Material Properties and Composition

Dielectric elastomer actuators consist of soft, stretchable elastomeric polymers that exhibit high elasticity and large strain capability, enabling flexible and lightweight actuation. Piezo actuators are made from crystalline ceramic materials, such as lead zirconate titanate (PZT), which offer high stiffness, rapid response, and precise displacement control but limited strain range. Your choice between these actuators will depend on the requirement for flexibility and large deformation versus high force and precision.

Response Time and Actuation Speed

Dielectric elastomer actuators offer faster response times and higher actuation speeds compared to piezo actuators due to their low mass and high strain capabilities. While piezo actuators excel in precision and force output, their response speed is generally slower because of the stiffness and limited deformation range. Your choice between these actuators should consider that dielectric elastomers enable rapid, large deformations ideal for dynamic applications.

Energy Efficiency and Power Consumption

Dielectric elastomer actuators (DEAs) exhibit high energy efficiency due to their low mechanical losses and ability to undergo large deformations with minimal input energy, resulting in reduced power consumption compared to piezoelectric actuators. Piezo actuators typically consume more power because they require continuous electric fields to maintain displacement and generate heat during operation. The inherent low driving voltage and elastic energy storage in DEAs contribute to superior energy-saving performance in applications requiring dynamic actuation.

Displacement Range and Force Output

Dielectric elastomer actuators (DEAs) typically offer a larger displacement range, often exceeding 100% strain, making them ideal for applications requiring significant flexibility and stretchability. In contrast, piezoelectric actuators provide higher force output with precision, capable of generating forces in the Newton range but usually limited to micron-scale displacements. The choice between DEA and piezo actuator depends on the trade-off between displacement amplitude and force requirements in specific applications.

Durability and Operational Lifespan

Dielectric elastomer actuators typically offer longer durability and a more extended operational lifespan compared to piezo actuators due to their flexible polymer structure that withstands repeated mechanical stress without significant degradation. Piezo actuators, while providing high precision and force output, often experience wear and fatigue over time, especially under continuous high-frequency operation, limiting their longevity. Choosing your actuator depends on balancing the need for durability with performance requirements in your specific application.

Application Areas and Industry Uses

Dielectric elastomer actuators excel in soft robotics, wearable devices, and biomedical applications due to their flexibility and high energy density, making them suitable for adaptive and bio-integrated systems. Piezo actuators dominate precision industries such as semiconductor manufacturing, microscopy, and aerospace, offering fast response times and high-resolution control essential for micromanipulation and vibration damping. Your choice between these actuators depends on whether your application prioritizes large, compliant deformations or ultra-precise, high-frequency motions.

Advantages and Limitations Comparison

Dielectric elastomer actuators offer high strain, lightweight construction, and energy efficiency, making them ideal for flexible, soft robotics and wearable devices, while piezo actuators provide superior precision, fast response times, and high force output, suited for applications requiring exact positioning and stability. Limitations of dielectric elastomer actuators include lower force generation and sensitivity to environmental factors like humidity, whereas piezo actuators face challenges such as limited displacement range and potential material brittleness. Your choice depends on whether you prioritize large, flexible movement or precise, high-force actuation in your project.

Future Trends in Soft and Precision Actuation

Dielectric elastomer actuators (DEAs) offer significant advantages in soft, flexible actuation with high strain and low weight, making them ideal for wearable and bio-inspired robotics. Piezo actuators excel in precision applications due to their high response speed, force density, and nanometer-scale positional accuracy, which are critical for microelectromechanical systems (MEMS) and optical devices. Future trends indicate hybrid systems combining DEA's large deformation capabilities with piezo actuators' precision control, driven by advances in material science and nanoscale fabrication technologies.

dielectric elastomer actuator vs piezo actuator Infographic

libmatt.com

libmatt.com