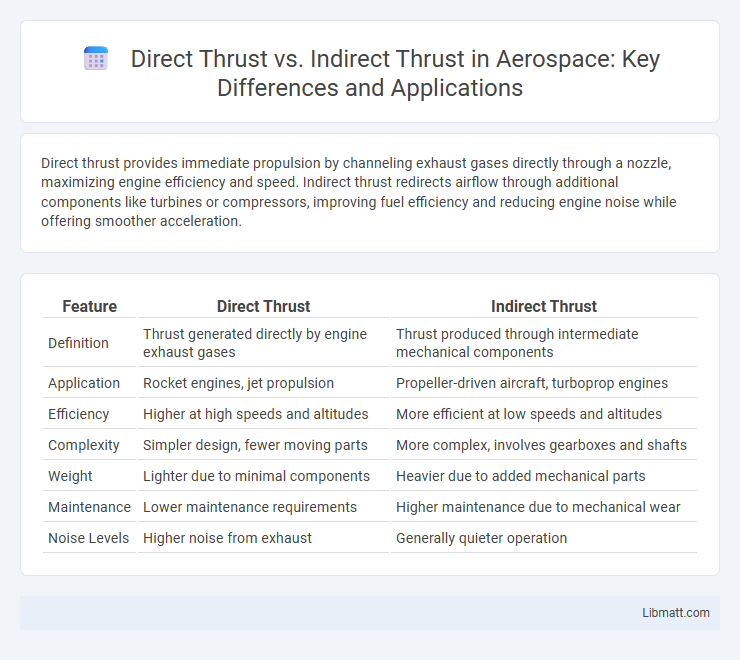

Direct thrust provides immediate propulsion by channeling exhaust gases directly through a nozzle, maximizing engine efficiency and speed. Indirect thrust redirects airflow through additional components like turbines or compressors, improving fuel efficiency and reducing engine noise while offering smoother acceleration.

Table of Comparison

| Feature | Direct Thrust | Indirect Thrust |

|---|---|---|

| Definition | Thrust generated directly by engine exhaust gases | Thrust produced through intermediate mechanical components |

| Application | Rocket engines, jet propulsion | Propeller-driven aircraft, turboprop engines |

| Efficiency | Higher at high speeds and altitudes | More efficient at low speeds and altitudes |

| Complexity | Simpler design, fewer moving parts | More complex, involves gearboxes and shafts |

| Weight | Lighter due to minimal components | Heavier due to added mechanical parts |

| Maintenance | Lower maintenance requirements | Higher maintenance due to mechanical wear |

| Noise Levels | Higher noise from exhaust | Generally quieter operation |

Introduction to Thrust Mechanisms

Direct thrust mechanisms generate force by expelling mass directly through propulsion systems such as rocket engines or jet turbines, converting fuel energy into kinetic energy. Indirect thrust involves utilizing external mediums like air or water, where the propulsion system imparts energy to the surrounding fluid, creating a reaction force that propels the vehicle forward. Understanding the fundamental differences between direct and indirect thrust is essential for optimizing performance in aerospace and marine propulsion technologies.

Defining Direct Thrust

Direct thrust refers to the propulsion force generated by the engine expelling exhaust gases straight backward, resulting in immediate forward motion of the vehicle or aircraft. This method maximizes efficiency by converting the engine's energy directly into linear momentum without intermediate mechanical components. It contrasts with indirect thrust systems, where force is transmitted through additional mechanisms before propelling the vehicle.

Understanding Indirect Thrust

Indirect thrust occurs when engine exhaust gases interact with external surfaces such as wings or nozzle contours to generate additional thrust, enhancing overall propulsion efficiency. This phenomenon significantly contributes to the total thrust in turbofan engines, where bypass air creates momentum differently from direct jet exhaust. Understanding indirect thrust allows aerospace engineers to optimize engine designs for improved fuel efficiency and reduced noise emissions.

Key Differences Between Direct and Indirect Thrust

Direct thrust generates propulsion by expelling mass directly in the opposite direction to movement, often seen in rocket engines where fuel combustion produces high-speed exhaust. Indirect thrust involves intermediaries such as air or fluids being accelerated by the engine to create force, typical in jet engines where air is compressed, mixed with fuel, and expelled. The key difference lies in the method of momentum transfer: direct thrust expels propellant mass directly, while indirect thrust accelerates surrounding medium to produce motion.

Advantages of Direct Thrust Systems

Direct thrust systems offer higher efficiency by minimizing energy losses through fewer mechanical components, resulting in improved propulsion performance. These systems provide quicker response times and greater control precision, essential for applications requiring rapid adjustments. You benefit from reduced maintenance costs and enhanced reliability due to the simpler design and fewer wear-prone parts.

Benefits of Indirect Thrust Approaches

Indirect thrust approaches offer enhanced fuel efficiency by optimizing engine performance through controlled airflow redirection, reducing overall operational costs. These methods increase safety margins by minimizing direct exposure to high-temperature exhaust gases, thereby preserving engine integrity and extending maintenance intervals. Your aircraft benefits from improved noise reduction and environmental compliance due to the smoother, less turbulent thrust distribution typical of indirect thrust systems.

Applications of Direct Thrust in Industry

Direct Thrust is widely applied in industry for precise control of fluid flow, particularly in aerospace propulsion and industrial compressors where quick response and high efficiency are critical. Its ability to generate force without intermediate mechanisms makes it ideal for applications in jet engines, rocket propulsion, and advanced manufacturing processes requiring rapid directional changes. The use of Direct Thrust enhances system reliability, reduces maintenance requirements, and improves overall energy efficiency in heavy-duty industrial equipment.

Uses of Indirect Thrust in Modern Technology

Indirect thrust is commonly utilized in turbofan engines of commercial airliners, where bypass air generates additional thrust without burning extra fuel, enhancing fuel efficiency and reducing noise. This technology is critical in modern jet propulsion, improving environmental performance by lowering emissions and conserving fuel resources. Indirect thrust mechanisms also find applications in hybrid propulsion systems, balancing power output and operational economy in aerospace engineering.

Efficiency Comparison: Direct vs Indirect Thrust

Direct thrust systems deliver propulsion by converting fuel energy directly into mechanical force, resulting in higher overall efficiency due to minimal energy loss. Indirect thrust mechanisms involve intermediate steps such as turbines or compressors, which introduce energy conversion inefficiencies and reduce the net thrust output. Consequently, direct thrust engines typically achieve better fuel economy and performance metrics, especially in high-speed and aerospace applications.

Future Developments in Thrust Technologies

Future developments in direct thrust technology emphasize increased efficiency and reduced emissions through novel propellant compositions and advanced ion propulsion systems. Indirect thrust advancements focus on optimizing exhaust flow dynamics and incorporating hybrid electric systems to enhance fuel economy and thrust control. Both technologies leverage artificial intelligence for precision thrust modulation and real-time system diagnostics.

Direct Thrust vs Indirect Thrust Infographic

libmatt.com

libmatt.com