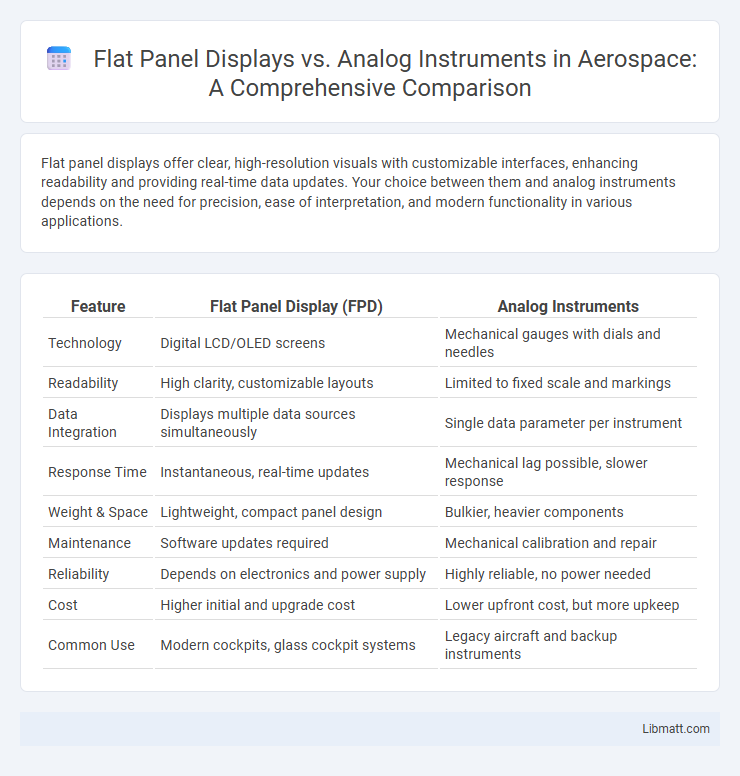

Flat panel displays offer clear, high-resolution visuals with customizable interfaces, enhancing readability and providing real-time data updates. Your choice between them and analog instruments depends on the need for precision, ease of interpretation, and modern functionality in various applications.

Table of Comparison

| Feature | Flat Panel Display (FPD) | Analog Instruments |

|---|---|---|

| Technology | Digital LCD/OLED screens | Mechanical gauges with dials and needles |

| Readability | High clarity, customizable layouts | Limited to fixed scale and markings |

| Data Integration | Displays multiple data sources simultaneously | Single data parameter per instrument |

| Response Time | Instantaneous, real-time updates | Mechanical lag possible, slower response |

| Weight & Space | Lightweight, compact panel design | Bulkier, heavier components |

| Maintenance | Software updates required | Mechanical calibration and repair |

| Reliability | Depends on electronics and power supply | Highly reliable, no power needed |

| Cost | Higher initial and upgrade cost | Lower upfront cost, but more upkeep |

| Common Use | Modern cockpits, glass cockpit systems | Legacy aircraft and backup instruments |

Introduction to Flat Panel Displays and Analog Instruments

Flat panel displays utilize advanced digital technology to provide high-resolution visual information with enhanced clarity and compact form factors, making them ideal for modern instrumentation. Analog instruments rely on mechanical or electromechanical components to display measurements through physical indicators like needles or dials, offering intuitive real-time readings but limited scalability. The shift from analog to flat panel displays enhances data integration, precision, and versatility in various applications such as aerospace, automotive, and industrial monitoring.

Evolution of Display Technologies

Flat panel display technology evolved from analog instruments by transitioning from bulky, mechanical gauges to sleek, digital screens that offer higher resolution and dynamic visualizations. The shift incorporates advanced materials like LCD, OLED, and LED, enhancing brightness, contrast, and energy efficiency compared to traditional analog dials. Modern flat panel displays enable real-time data integration and customizable interfaces, significantly improving user interaction and information accuracy over static analog instruments.

Key Components and Operating Principles

Flat panel displays utilize thin-film transistor (TFT) or organic light-emitting diode (OLED) technology to control pixel illumination electronically, enabling high-resolution digital visualization. Analog instruments rely on mechanical components such as needles, springs, and dials to translate physical phenomena into readable analog signals through continuous movement. The digital operation of flat panel displays allows precise and customizable data representation, while analog instruments depend on direct physical manipulation for real-time measurement feedback.

Accuracy and Precision Comparison

Flat panel displays offer higher accuracy and precision due to digital signal processing and pixel-based resolution, minimizing human error and parallax issues inherent in analog instruments. Analog instruments rely on mechanical components and pointer movements, which can cause reading inaccuracies and reduced repeatability, especially under vibrations or varying environmental conditions. The digital nature of flat panel displays ensures consistent, quantifiable measurements, making them superior for applications demanding exact data interpretation.

Visual Clarity and Readability

Flat panel displays offer superior visual clarity and readability through high-resolution screens with vibrant colors and adjustable brightness, enabling clear visibility even in low-light conditions. Analog instruments rely on physical dials and needles, which can be harder to read quickly and accurately, especially in complex or low-contrast environments. Enhanced pixel density and anti-glare technology in flat panels significantly reduce eye strain compared to the static, often reflective surfaces of analog gauges.

User Interface and Customization

Flat panel displays offer advanced user interfaces with touchscreens, intuitive menus, and real-time data visualization, allowing for greater customization to suit your specific monitoring needs. Analog instruments rely on fixed dials and gauges, providing limited interaction and customization options. The enhanced flexibility of flat panel displays improves usability and efficiency in dynamic environments.

Durability and Environmental Suitability

Flat panel displays offer enhanced durability with resistance to shock and vibration, making them suitable for harsh industrial environments, whereas analog instruments often have mechanical components prone to wear and damage. Flat panels function reliably across a wider range of temperatures and humidity levels, benefiting from sealed designs that minimize exposure to dust and moisture. Analog instruments may suffer from calibration drift and mechanical failure in extreme environmental conditions, limiting their operational lifespan compared to rugged flat panel solutions.

Maintenance and Longevity

Flat panel displays require less maintenance due to fewer moving parts and advanced self-diagnostic features, enhancing their operational reliability. Analog instruments, while robust, often demand regular calibration and mechanical upkeep to maintain accuracy over time. Your choice between flat panel displays and analog instruments impacts long-term maintenance costs and device lifespan significantly.

Cost Considerations and ROI

Flat panel displays generally involve higher initial costs compared to analog instruments due to advanced technology and integration features. However, their long-term ROI is enhanced by lower maintenance expenses, improved accuracy, and enhanced data visualization, which reduce operational errors and downtime. Your investment in flat panel displays can lead to significant cost savings and efficiency gains over analog counterparts in industrial and commercial applications.

Future Trends in Instrumentation

Flat panel displays in instrumentation are increasingly integrating high-resolution touchscreens and advanced graphical user interfaces, enabling more intuitive data visualization and remote monitoring capabilities. Analog instruments, while still valued for their reliability and simplicity, are gradually being replaced or supplemented by digital counterparts that support IoT connectivity and real-time data analytics. The future trends emphasize smart instrumentation systems featuring enhanced precision, predictive maintenance, and seamless integration with Industry 4.0 technologies.

flat panel display vs analog instruments Infographic

libmatt.com

libmatt.com