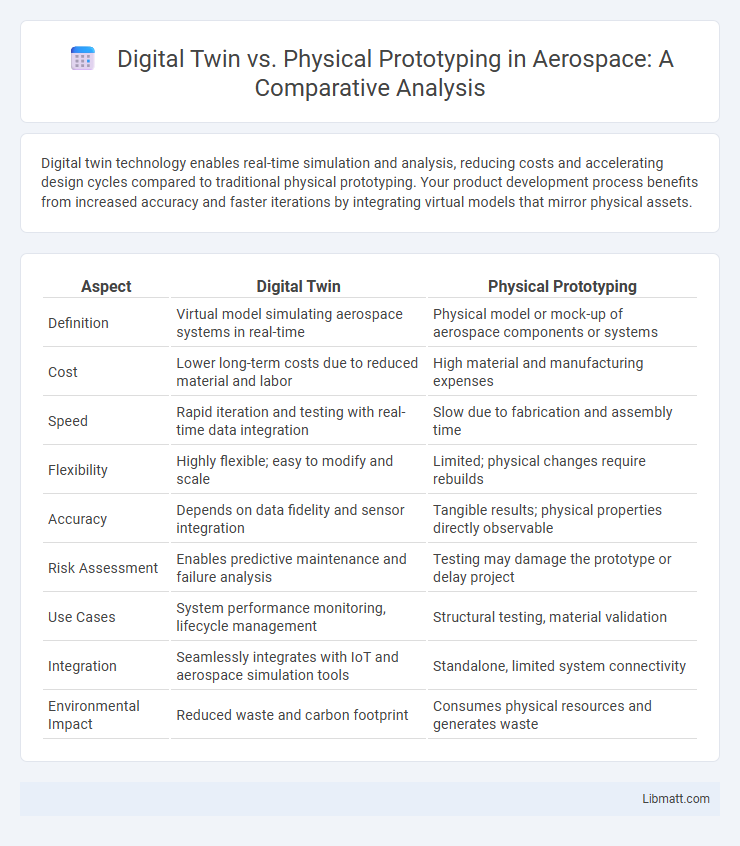

Digital twin technology enables real-time simulation and analysis, reducing costs and accelerating design cycles compared to traditional physical prototyping. Your product development process benefits from increased accuracy and faster iterations by integrating virtual models that mirror physical assets.

Table of Comparison

| Aspect | Digital Twin | Physical Prototyping |

|---|---|---|

| Definition | Virtual model simulating aerospace systems in real-time | Physical model or mock-up of aerospace components or systems |

| Cost | Lower long-term costs due to reduced material and labor | High material and manufacturing expenses |

| Speed | Rapid iteration and testing with real-time data integration | Slow due to fabrication and assembly time |

| Flexibility | Highly flexible; easy to modify and scale | Limited; physical changes require rebuilds |

| Accuracy | Depends on data fidelity and sensor integration | Tangible results; physical properties directly observable |

| Risk Assessment | Enables predictive maintenance and failure analysis | Testing may damage the prototype or delay project |

| Use Cases | System performance monitoring, lifecycle management | Structural testing, material validation |

| Integration | Seamlessly integrates with IoT and aerospace simulation tools | Standalone, limited system connectivity |

| Environmental Impact | Reduced waste and carbon footprint | Consumes physical resources and generates waste |

Introduction to Digital Twins and Physical Prototyping

Digital twins create virtual replicas of physical assets, enabling real-time simulation and performance analysis through IoT sensor data integration. Physical prototyping involves building tangible models to test functionality, design, and ergonomics before mass production. Digital twins accelerate development cycles and reduce costs, while physical prototypes provide hands-on validation critical for tactile evaluation and final adjustments.

Key Differences Between Digital Twins and Physical Prototypes

Digital twins provide real-time data and simulations reflecting actual performance, whereas physical prototypes offer tangible models for hands-on testing and validation. Digital twins enable rapid iteration and predictive analysis without the costs and time associated with manufacturing physical units. Your development process benefits from enhanced accuracy and efficiency by integrating both digital twin simulations and physical prototyping when appropriate.

Cost Implications: Digital vs Physical Prototyping

Digital twin technology significantly reduces cost implications compared to physical prototyping by minimizing material waste, labor, and production time. You can simulate multiple design iterations and identify potential issues virtually, avoiding expensive physical trial-and-error processes. Physical prototyping requires investment in raw materials and manufacturing resources, often leading to higher expenses and delayed feedback cycles.

Speed and Time Efficiency Comparison

Digital twin technology accelerates product development by enabling real-time simulations and iterative testing without physical constraints, reducing design cycle times significantly. Physical prototyping requires manufacturing and assembly, which prolongs development phases and increases time consumption due to manual adjustments and physical testing. The use of digital twins can cut time-to-market by up to 50% compared to traditional physical prototyping methods.

Accuracy and Realism: Virtual vs Physical Models

Digital twin technology offers high accuracy and realism by creating dynamic, real-time virtual models that replicate the behavior and conditions of physical assets through sensor data integration. Physical prototyping provides tangible, real-world validation of design, capturing nuanced material properties and unforeseen interactions that virtual models may overlook. While digital twins excel in iterative testing and predictive analysis, physical prototypes remain essential for validating tactile feedback and manufacturing feasibility.

Scalability of Testing and Iteration

Digital twin technology enables scalable testing and rapid iteration by simulating multiple scenarios simultaneously in a virtual environment, reducing time and costs compared to physical prototyping. Physical prototyping requires constructing and modifying tangible models, which limits scalability due to material constraints and longer lead times. Digital twins facilitate continuous updates and real-time data integration, enhancing iterative design processes across diverse conditions without extensive physical resource consumption.

Integration with Industry 4.0 Technologies

Digital twins offer seamless integration with Industry 4.0 technologies by providing real-time data analytics, IoT connectivity, and AI-driven insights that enhance predictive maintenance and process optimization. Physical prototyping lacks the continuous feedback loop and digital adaptability necessary for fully leveraging smart manufacturing systems and cyber-physical processes. Your ability to accelerate innovation and reduce time-to-market improves significantly when utilizing digital twins within the Industry 4.0 framework.

Environmental Impact and Sustainability Considerations

Digital twin technology significantly reduces environmental impact by minimizing the need for physical prototypes, which decreases material waste and energy consumption during manufacturing processes. Physical prototyping often involves resource-intensive production cycles and disposal challenges, while digital twins enable virtual testing and iteration, promoting sustainable design practices. Your product development can become more eco-friendly and cost-effective by leveraging digital twins for continuous optimization without the environmental footprint of traditional prototyping.

Case Studies: Success Stories and Practical Applications

Digital twin technology has revolutionized industries by enabling real-time simulation and performance analysis, as demonstrated in General Electric's jet engine maintenance program which reduced downtime by 20%. Siemens implemented digital twins in manufacturing processes, achieving a 30% increase in production efficiency and faster time-to-market compared to traditional physical prototyping. Automotive giant Ford leveraged digital twin models to optimize vehicle design, cutting prototype costs by 40% while accelerating development cycles.

Choosing the Right Approach: Factors to Consider

Selecting between digital twin technology and physical prototyping depends on factors such as project complexity, cost constraints, and turnaround time. Digital twins excel in providing real-time data integration and iterative design optimization, ideal for dynamic and complex systems. Physical prototyping remains crucial for tangible, hands-on validation and testing where material properties and user interaction are critical.

Digital twin vs Physical prototyping Infographic

libmatt.com

libmatt.com