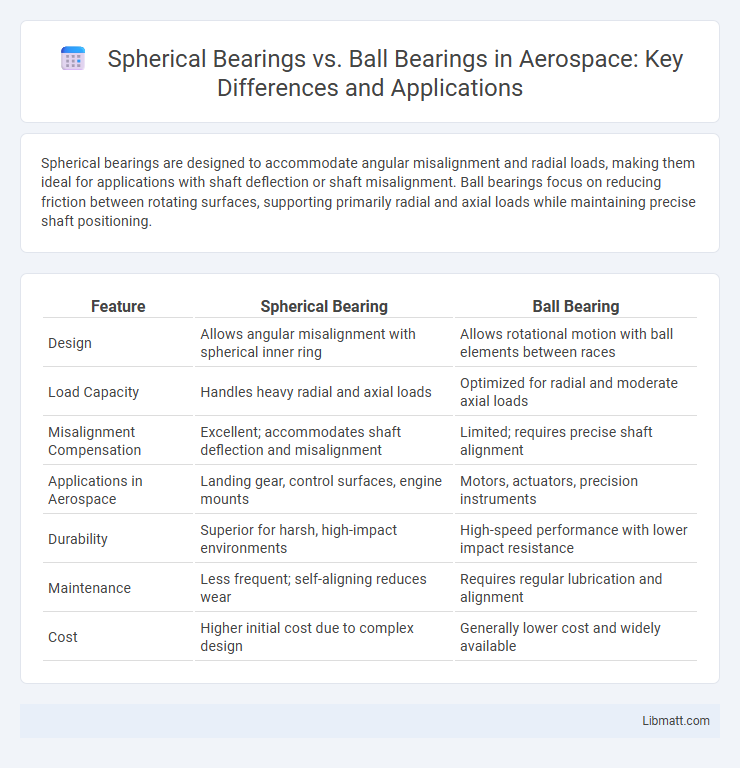

Spherical bearings are designed to accommodate angular misalignment and radial loads, making them ideal for applications with shaft deflection or shaft misalignment. Ball bearings focus on reducing friction between rotating surfaces, supporting primarily radial and axial loads while maintaining precise shaft positioning.

Table of Comparison

| Feature | Spherical Bearing | Ball Bearing |

|---|---|---|

| Design | Allows angular misalignment with spherical inner ring | Allows rotational motion with ball elements between races |

| Load Capacity | Handles heavy radial and axial loads | Optimized for radial and moderate axial loads |

| Misalignment Compensation | Excellent; accommodates shaft deflection and misalignment | Limited; requires precise shaft alignment |

| Applications in Aerospace | Landing gear, control surfaces, engine mounts | Motors, actuators, precision instruments |

| Durability | Superior for harsh, high-impact environments | High-speed performance with lower impact resistance |

| Maintenance | Less frequent; self-aligning reduces wear | Requires regular lubrication and alignment |

| Cost | Higher initial cost due to complex design | Generally lower cost and widely available |

Understanding Spherical Bearings

Spherical bearings are designed to accommodate angular misalignment and rotational motion, making them ideal for applications where shaft deflection or misalignment occurs. Unlike ball bearings, which primarily support radial and axial loads with limited tolerance for misalignment, spherical bearings consist of an inner ring with a convex outer surface that fits into a concave outer ring, enabling self-alignment. Your machinery benefits from spherical bearings when flexibility and durability under varying load angles are crucial for optimal performance.

What Is a Ball Bearing?

A ball bearing is a type of rolling-element bearing that uses spherical balls to maintain the separation between the bearing races, reducing friction and supporting radial and axial loads in machinery. Unlike spherical bearings, which accommodate angular misalignment, ball bearings are designed primarily for smooth rotational motion with minimal play. Your choice depends on the specific application's load direction and alignment requirements.

Key Design Differences

Spherical bearings feature a self-aligning design with an inner ring that rotates within a spherical outer ring, allowing for angular misalignment and enhanced adaptability in dynamic loads. Ball bearings consist of a series of balls contained between inner and outer races, optimized for rotational precision and low friction under radial and axial loads. The key design difference lies in the spherical bearing's ability to accommodate shaft misalignment, whereas ball bearings provide superior speed and efficiency in applications with minimal shaft deflection.

Load Handling Capabilities

Spherical bearings excel in handling heavy radial and axial loads while accommodating misalignment and shaft deflections, making them ideal for applications with varying load directions. Ball bearings primarily manage lower radial and axial loads with precision at higher speeds but offer limited misalignment correction. The choice between spherical and ball bearings depends on load magnitude, direction, and angular displacement requirements.

Misalignment Accommodation

Spherical bearings are specifically designed to accommodate angular misalignment between shaft and housing, making them ideal for applications where shaft deflection or installation errors occur. Ball bearings, while capable of handling some misalignment, have limited tolerance and are better suited for precise alignment conditions. Your choice depends on the level of misalignment anticipated in the mechanical system.

Durability and Maintenance

Spherical bearings excel in durability due to their ability to accommodate misalignment and reduce stress, making them ideal for heavy-duty applications where shaft deflection occurs. Ball bearings, while offering smooth rotation and lower friction, may require more frequent maintenance to address wear and lubrication needs under high-load or misalignment conditions. Choosing spherical bearings for your equipment can minimize downtime and maintenance costs by enhancing load distribution and extending service life.

Common Applications

Spherical bearings are commonly used in heavy machinery, automotive suspensions, and industrial equipment where accommodation of angular misalignment and high load capacity are crucial. Ball bearings are widely applied in electric motors, household appliances, and precision instruments due to their ability to support radial and axial loads with low friction and high-speed capability. Selecting between spherical and ball bearings depends on the specific application's need for load type, misalignment tolerance, and operational speed.

Cost Comparison

Spherical bearings generally have a higher initial cost compared to ball bearings due to their complex design and ability to accommodate misalignment and heavy loads. Ball bearings are more cost-effective for applications with lighter loads and minimal misalignment, making them ideal for budget-sensitive projects. For industries requiring durability and maintenance of alignment under dynamic conditions, investing in spherical bearings offers long-term savings despite the upfront expense.

Performance in Extreme Conditions

Spherical bearings excel in extreme conditions due to their self-aligning capability, allowing them to accommodate misalignment and heavy loads without compromising performance. Ball bearings, while efficient under moderate conditions, tend to suffer from stress and faster wear when exposed to high loads or misalignment. Your choice should prioritize spherical bearings for durability and reliability in harsh environments requiring superior alignment tolerance.

Choosing the Right Bearing for Your Needs

Selecting between spherical bearings and ball bearings depends on application demands, load types, and misalignment tolerance; spherical bearings excel in handling heavy radial loads and accommodating angular misalignment, making them ideal for industrial machinery and automotive suspensions. Ball bearings, optimized for high-speed rotation and lower friction, are preferred in precision instruments, electric motors, and household appliances where smooth motion is crucial. Evaluating factors such as load capacity, operating speed, alignment requirements, and environmental conditions ensures the right bearing choice for optimal performance and longevity.

Spherical Bearing vs Ball Bearing Infographic

libmatt.com

libmatt.com