Certified aircraft undergo rigorous testing and meet strict regulatory standards to ensure safety and reliability, making them suitable for commercial and private use. Experimental aircraft offer greater design flexibility and cost savings for hobbyists or developers but require your careful attention to operational limitations and maintenance requirements.

Table of Comparison

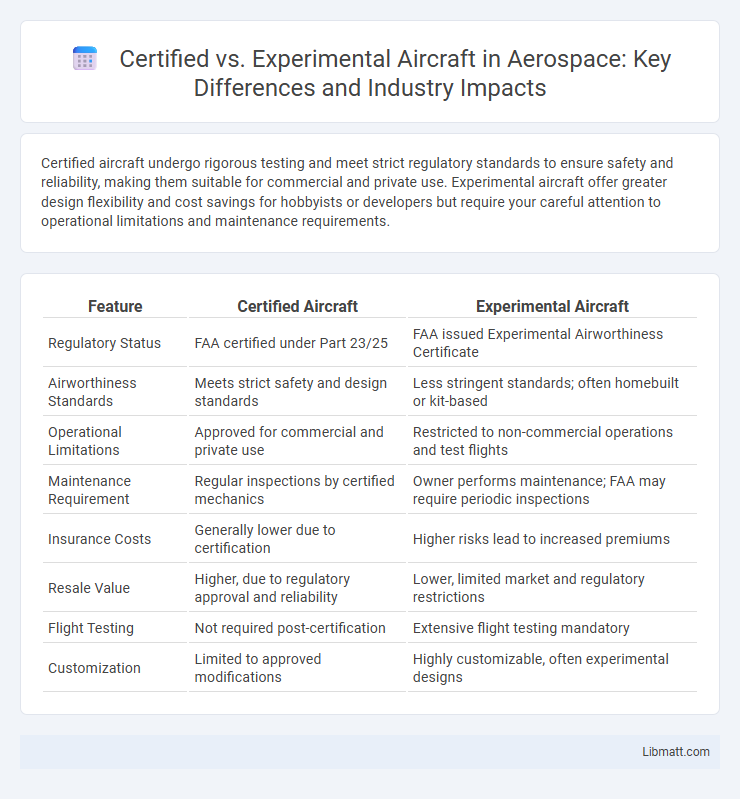

| Feature | Certified Aircraft | Experimental Aircraft |

|---|---|---|

| Regulatory Status | FAA certified under Part 23/25 | FAA issued Experimental Airworthiness Certificate |

| Airworthiness Standards | Meets strict safety and design standards | Less stringent standards; often homebuilt or kit-based |

| Operational Limitations | Approved for commercial and private use | Restricted to non-commercial operations and test flights |

| Maintenance Requirement | Regular inspections by certified mechanics | Owner performs maintenance; FAA may require periodic inspections |

| Insurance Costs | Generally lower due to certification | Higher risks lead to increased premiums |

| Resale Value | Higher, due to regulatory approval and reliability | Lower, limited market and regulatory restrictions |

| Flight Testing | Not required post-certification | Extensive flight testing mandatory |

| Customization | Limited to approved modifications | Highly customizable, often experimental designs |

Introduction to Certified and Experimental Aircraft

Certified aircraft undergo rigorous testing and meet strict regulatory standards set by aviation authorities like the FAA, ensuring safety, reliability, and conformity to established airworthiness criteria. Experimental aircraft do not conform to these certification standards and are primarily used for research, development, or personal projects, often allowing for innovative designs and modifications but with operating limitations. The distinction between certified and experimental aircraft significantly impacts maintenance requirements, pilot qualifications, and operational permissions under aviation regulations.

Understanding Aircraft Certification Categories

Certified aircraft undergo rigorous testing and meet strict Federal Aviation Administration (FAA) standards to ensure safety and reliability for general use. Experimental aircraft, often used for research, development, or amateur-built projects, operate under less stringent regulations but require careful adherence to operating limitations. Understanding these certification categories is crucial for your decisions related to aircraft ownership, usage, and maintenance compliance.

Key Features of Certified Aircraft

Certified aircraft undergo rigorous regulatory scrutiny to meet stringent safety, design, and performance standards set by aviation authorities like the FAA or EASA. These aircraft feature standardized manufacturing processes, comprehensive maintenance programs, and mandatory compliance with airworthiness directives. Advanced safety systems, proven reliability, and validated operational data are central to the certified aircraft's design, ensuring high levels of pilot and passenger confidence.

Advantages of Owning a Certified Aircraft

Owning a certified aircraft offers significant advantages including adherence to stringent FAA safety standards and comprehensive maintenance documentation, which increase reliability and resale value. Certified aircraft benefit from broader insurance options and access to commercial operations, enhancing versatility for business or charter use. These aircraft typically have standardized parts and manufacturer support, simplifying repairs and ensuring compliance with regulatory requirements.

Exploring the World of Experimental Aircraft

Experimental aircraft offer aviation enthusiasts unique opportunities for customization, innovation, and hands-on building, contrasting with certified aircraft that meet strict regulatory standards set by agencies like the FAA. These experimental planes often feature cutting-edge technologies, lightweight materials, and unconventional designs that push the boundaries of traditional aviation. Pilots flying experimental aircraft must adhere to specific operating limitations and maintenance regimes, ensuring safety despite the less standardized nature of these personalized machines.

Benefits and Drawbacks of Experimental Aircraft

Experimental aircraft offer significant benefits such as lower costs, increased design flexibility, and the ability to innovate with new technologies and materials outside strict certification constraints. However, these aircraft come with drawbacks including limited regulatory oversight, potential safety risks due to less rigorous testing, and restrictions on commercial use or carrying passengers for hire. Owners must assume greater responsibility for maintenance and airworthiness, which can impact insurance and resale value compared to certified aircraft.

Regulatory Requirements for Certified vs Experimental Aircraft

Certified aircraft must comply with stringent Federal Aviation Administration (FAA) regulations involving rigorous design, manufacture, and maintenance standards to ensure safety and airworthiness. Experimental aircraft operate under more flexible FAA rules primarily intended for research, development, or amateur-built projects, often requiring restrictions on flight locations and usage. While certified aircraft can be used commercially, experimental aircraft are typically limited to personal, educational, or testing purposes under specific regulatory conditions.

Safety Considerations and Maintenance Differences

Certified aircraft undergo rigorous safety testing and must comply with strict regulatory standards, ensuring reliability and predictable maintenance procedures. Experimental aircraft, while offering design flexibility, may present higher risks due to less standardized safety requirements and potentially variable build quality. Your maintenance routine will differ significantly, with certified aircraft requiring mandated inspections, whereas experimental aircraft depend more on owner diligence and customized upkeep protocols.

Cost Comparison: Certified Aircraft vs Experimental Aircraft

Certified aircraft typically incur higher costs due to rigorous manufacturing standards, comprehensive inspections, and adherence to Federal Aviation Administration (FAA) regulations, often resulting in expenses exceeding $100,000 for small general aviation planes. Experimental aircraft, built by amateurs or kit manufacturers, generally offer lower acquisition costs, sometimes under $50,000, but may involve additional expenses for builder time, tool investment, and potential modifications to meet airworthiness requirements. Maintenance and operational costs can favor certified aircraft through established support networks, whereas experimental aircraft might have variable costs depending on builder expertise and parts availability.

Which Aircraft Type Is Right for You?

Certified aircraft undergo rigorous FAA testing and meet strict safety and performance standards, making them ideal for pilots prioritizing reliability and resale value. Experimental aircraft provide flexibility for innovation and customization, often appealing to enthusiasts seeking unique designs or cost savings. Choosing the right type depends on your priorities for safety certification, customization freedom, budget, and intended use.

Certified vs Experimental aircraft Infographic

libmatt.com

libmatt.com