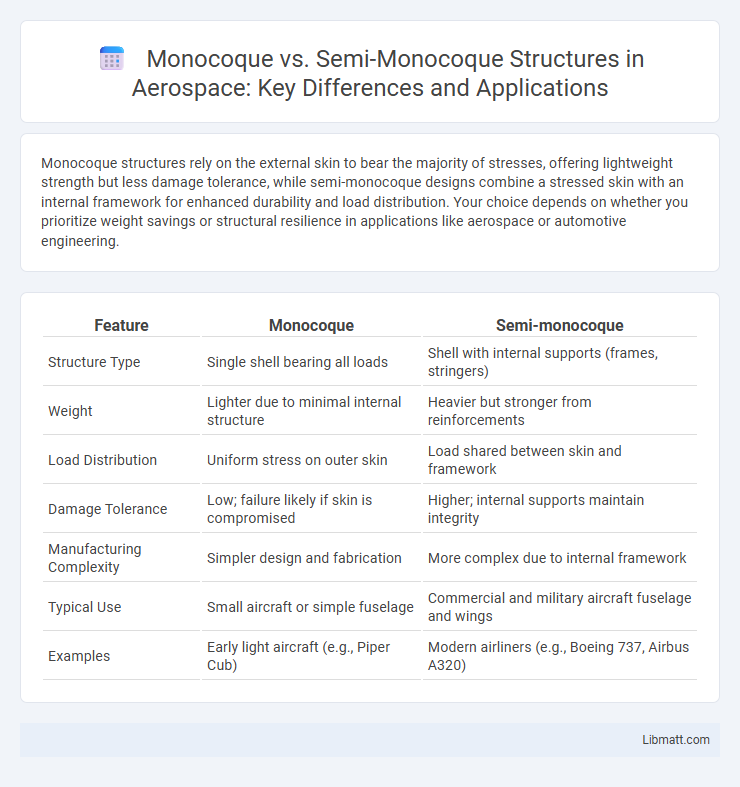

Monocoque structures rely on the external skin to bear the majority of stresses, offering lightweight strength but less damage tolerance, while semi-monocoque designs combine a stressed skin with an internal framework for enhanced durability and load distribution. Your choice depends on whether you prioritize weight savings or structural resilience in applications like aerospace or automotive engineering.

Table of Comparison

| Feature | Monocoque | Semi-monocoque |

|---|---|---|

| Structure Type | Single shell bearing all loads | Shell with internal supports (frames, stringers) |

| Weight | Lighter due to minimal internal structure | Heavier but stronger from reinforcements |

| Load Distribution | Uniform stress on outer skin | Load shared between skin and framework |

| Damage Tolerance | Low; failure likely if skin is compromised | Higher; internal supports maintain integrity |

| Manufacturing Complexity | Simpler design and fabrication | More complex due to internal framework |

| Typical Use | Small aircraft or simple fuselage | Commercial and military aircraft fuselage and wings |

| Examples | Early light aircraft (e.g., Piper Cub) | Modern airliners (e.g., Boeing 737, Airbus A320) |

Introduction to Monocoque and Semi-Monocoque Structures

Monocoque and semi-monocoque structures are key design approaches in aerospace and automotive engineering, where the shell or skin of the vehicle supports most or all of the load. Monocoque structures rely entirely on the external skin for strength, offering lightweight efficiency but limited damage tolerance. Semi-monocoque constructions combine a load-bearing skin with an internal framework of stringers and frames, enhancing durability and structural integrity without significant weight increase, which can optimize your vehicle's performance and safety.

Historical Evolution of Structural Design

The historical evolution of aircraft structural design saw the transition from monocoque to semi-monocoque systems to enhance strength and durability while minimizing weight. Early aircraft relied on monocoque construction, where the outer skin bore most of the structural load, but this design lacked redundancy and was susceptible to damage. Semi-monocoque structures introduced an internal framework of ribs and longerons that supported the skin, distributing stress more efficiently and becoming the industry standard for modern aircraft fuselages.

Core Principles of Monocoque Construction

Monocoque construction relies on the external skin of the structure to bear all or most of the stresses, eliminating the need for an internal framework. This design principle maximizes strength-to-weight ratio, making it ideal for lightweight applications like automotive and aerospace engineering. Your choice between monocoque and semi-monocoque depends on the balance needed between structural rigidity and flexibility for maintenance or repair.

Defining Features of Semi-Monocoque Construction

Semi-monocoque construction features a framework of longitudinal stringers and transverse frames covered by a stressed skin, providing enhanced structural strength and damage tolerance compared to pure monocoque designs. This hybrid structure distributes loads more efficiently, combining the skin's load-bearing capacity with the internal support elements to resist bending and torsion. Commonly used in modern aircraft fuselages, semi-monocoque construction balances lightweight design with improved durability and repairability.

Material Selection and Structural Efficiency

Monocoque structures utilize a single shell of material, often advanced composites or aluminum alloys, providing high structural efficiency by evenly distributing stress throughout the skin, resulting in lightweight yet strong designs. Semi-monocoque construction combines an outer skin with internal frames and stringers made typically from aluminum or titanium, balancing material selection between rigidity and damage tolerance to optimize strength-to-weight ratio. The choice between these designs hinges on material properties such as tensile strength, fatigue resistance, and manufacturability, directly impacting the structure's efficiency and durability in aerospace and automotive applications.

Weight and Strength Comparison

Monocoque structures are lighter due to their integrated design, where the outer skin supports most of the load, resulting in reduced material usage. Semi-monocoque constructions combine a load-bearing skin with internal frames and stringers, offering enhanced strength and damage tolerance at the cost of added weight. Your choice depends on balancing the need for lightweight efficiency against structural robustness in aerospace or automotive applications.

Application in Aerospace and Automotive Industries

Monocoque structures, characterized by a single-shell load-bearing design, are widely used in lightweight aerospace applications where minimal weight and maximum strength are critical, such as in small aircraft fuselages and certain high-performance automotive racing chassis. Semi-monocoque designs, combining a load-bearing skin with an internal framework of ribs and stringers, dominate commercial aircraft construction and modern vehicle bodies due to their enhanced durability, damage tolerance, and ease of repair. The aerospace industry benefits from semi-monocoque's ability to distribute stresses efficiently, supporting larger, pressurized cabins, while the automotive sector leverages monocoque and semi-monocoque hybrids in unibody frames to improve crash safety and fuel efficiency.

Durability and Maintenance Considerations

Monocoque structures offer increased durability due to their integrated design, which distributes stress evenly across the shell, reducing weak points prone to failure. Semi-monocoque constructions enhance maintainability by combining a load-bearing frame with a stressed skin, allowing for easier inspection and repair of individual components. The semi-monocoque design is often preferred in aviation and automotive industries where balanced durability and straightforward maintenance are critical.

Cost Implications and Manufacturing Complexity

Monocoque structures typically incur higher manufacturing complexity and cost due to their reliance on a single, integrated shell that demands precise engineering and advanced materials. Semi-monocoque designs offer cost advantages by combining a load-bearing skin with internal supports, reducing material stress and simplifying production processes. The balance between structural efficiency and ease of assembly makes semi-monocoque a preferred choice in industries seeking cost-effective manufacturing without compromising strength.

Choosing the Right Structure: Key Factors to Consider

Choosing between monocoque and semi-monocoque structures depends on factors such as weight, strength, cost, and repairability. Monocoque designs offer lightweight efficiency and streamlined aerodynamics, ideal for high-performance applications, while semi-monocoque structures provide enhanced durability and easier maintenance through reinforced frames. Your choice should align with specific performance requirements and operational environments to balance structural integrity and practicality.

Monocoque vs Semi-monocoque Infographic

libmatt.com

libmatt.com