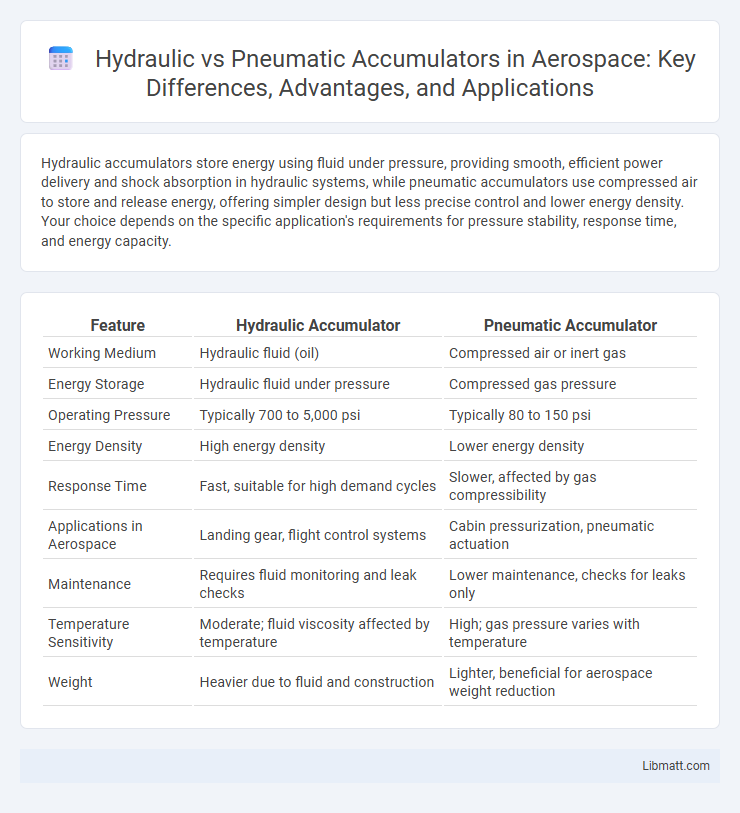

Hydraulic accumulators store energy using fluid under pressure, providing smooth, efficient power delivery and shock absorption in hydraulic systems, while pneumatic accumulators use compressed air to store and release energy, offering simpler design but less precise control and lower energy density. Your choice depends on the specific application's requirements for pressure stability, response time, and energy capacity.

Table of Comparison

| Feature | Hydraulic Accumulator | Pneumatic Accumulator |

|---|---|---|

| Working Medium | Hydraulic fluid (oil) | Compressed air or inert gas |

| Energy Storage | Hydraulic fluid under pressure | Compressed gas pressure |

| Operating Pressure | Typically 700 to 5,000 psi | Typically 80 to 150 psi |

| Energy Density | High energy density | Lower energy density |

| Response Time | Fast, suitable for high demand cycles | Slower, affected by gas compressibility |

| Applications in Aerospace | Landing gear, flight control systems | Cabin pressurization, pneumatic actuation |

| Maintenance | Requires fluid monitoring and leak checks | Lower maintenance, checks for leaks only |

| Temperature Sensitivity | Moderate; fluid viscosity affected by temperature | High; gas pressure varies with temperature |

| Weight | Heavier due to fluid and construction | Lighter, beneficial for aerospace weight reduction |

Introduction to Hydraulic and Pneumatic Accumulators

Hydraulic accumulators store energy by compressing fluid within a pressure vessel, providing smooth operation and shock absorption in hydraulic systems. Pneumatic accumulators use compressed air or gas to store energy, offering flexibility and cushioning in pneumatic applications. Both types optimize system efficiency by maintaining pressure stability and compensating for fluid or gas volume fluctuations.

Basic Working Principles

Hydraulic accumulators store energy by compressing hydraulic fluid within a gas-charged chamber, using the fluid's incompressibility to maintain pressure and absorb shocks. Pneumatic accumulators operate by compressing air or gas in a chamber, utilizing the gas's compressibility to store and release energy for system pressure stabilization. Both types serve to enhance system performance, but hydraulic accumulators focus on fluid dynamics, while pneumatic accumulators rely on gas compression principles.

Key Components Comparison

Hydraulic accumulators feature key components such as a pressure vessel, bladder or piston, and a hydraulic fluid chamber designed to store energy under fluid pressure. Pneumatic accumulators consist mainly of a compressed gas chamber, a separator like a bladder or piston, and an air reservoir to store energy via compressed air. Understanding these essential parts helps you choose the right accumulator type to match your system's pressure and energy storage requirements effectively.

Energy Storage Capabilities

Hydraulic accumulators store energy by compressing fluid, typically oil, under pressure in a sealed chamber, offering high energy density and immediate energy release for industrial and automotive applications. Pneumatic accumulators use compressed gas, usually air or nitrogen, to store energy, providing lower energy density but greater elasticity and smoother energy delivery in systems requiring flexible pressure management. Your choice between these accumulators depends on the required energy capacity, response time, and system pressure characteristics.

Pressure and Flow Characteristics

Hydraulic accumulators maintain high pressure consistently, typically ranging from 1,000 to 5,000 psi, enabling efficient energy storage and release for precise flow control in hydraulic systems. Pneumatic accumulators operate at significantly lower pressures, generally between 80 to 120 psi, resulting in less stable flow rates but faster pressure response due to gas compressibility. The incompressible nature of hydraulic fluid ensures smoother, more predictable flow delivery compared to the variable flow output influenced by gas expansion in pneumatic accumulators.

Application Areas and Use Cases

Hydraulic accumulators are commonly used in heavy machinery, industrial equipment, and automotive braking systems due to their ability to store significant amounts of liquid energy under high pressure, making them ideal for shock absorption, energy storage, and maintaining system pressure. Pneumatic accumulators find applications in air compression systems, pneumatic tools, and HVAC systems, where compressible gas storage provides cushioning, pressure stabilization, and energy release in lighter, lower-pressure environments. When choosing between these accumulators, consider your system's pressure requirements, fluid type, and application environment to ensure optimal performance and longevity.

Advantages of Hydraulic Accumulators

Hydraulic accumulators offer superior energy density compared to pneumatic accumulators, enabling more compact system designs and efficient energy storage. They provide precise pressure control and smoother fluid delivery, which improves system performance and reduces wear on hydraulic components. Their ability to handle higher pressures and deliver stable fluid flow makes hydraulic accumulators ideal for industrial machinery and heavy-duty applications.

Advantages of Pneumatic Accumulators

Pneumatic accumulators offer advantages such as faster response times and lighter weight compared to hydraulic accumulators, making them ideal for applications requiring quick actuation and reduced system mass. They operate effectively with compressible gases like air or nitrogen, providing excellent energy storage flexibility and improved safety due to lower fluid leak risks. Their simpler design and lower maintenance costs contribute to enhanced reliability in various industrial and automotive systems.

Limitations and Challenges

Hydraulic accumulators face limitations such as potential fluid leakage, pressure loss over time, and sensitivity to temperature variations affecting fluid viscosity. Pneumatic accumulators encounter challenges including gas compressibility causing less precise energy storage and pressure fluctuations influenced by ambient temperature changes. Both systems require careful maintenance to address seal wear and ensure consistent performance under varying operational conditions.

Choosing the Right Accumulator for Your System

Hydraulic accumulators store energy using incompressible fluid, providing high pressure and precise control, ideal for heavy-duty applications requiring consistent force. Pneumatic accumulators use compressed air or gas, offering lighter weight and quicker response, suited for systems where flexibility and shock absorption are prioritized. Choosing the right accumulator depends on Your system's pressure requirements, response time, and the type of energy storage best aligned with operational demands.

Hydraulic accumulator vs Pneumatic accumulator Infographic

libmatt.com

libmatt.com