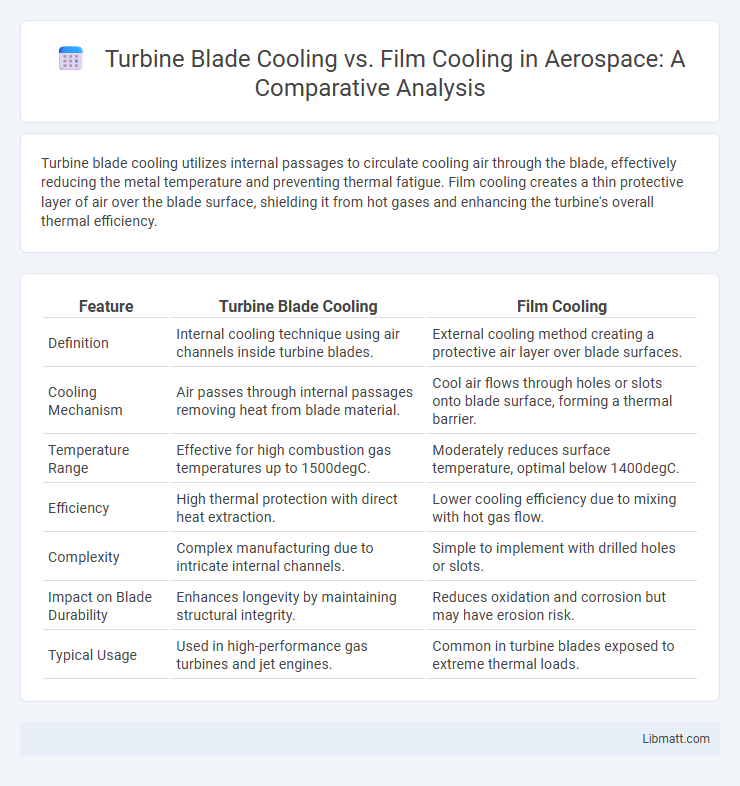

Turbine blade cooling utilizes internal passages to circulate cooling air through the blade, effectively reducing the metal temperature and preventing thermal fatigue. Film cooling creates a thin protective layer of air over the blade surface, shielding it from hot gases and enhancing the turbine's overall thermal efficiency.

Table of Comparison

| Feature | Turbine Blade Cooling | Film Cooling |

|---|---|---|

| Definition | Internal cooling technique using air channels inside turbine blades. | External cooling method creating a protective air layer over blade surfaces. |

| Cooling Mechanism | Air passes through internal passages removing heat from blade material. | Cool air flows through holes or slots onto blade surface, forming a thermal barrier. |

| Temperature Range | Effective for high combustion gas temperatures up to 1500degC. | Moderately reduces surface temperature, optimal below 1400degC. |

| Efficiency | High thermal protection with direct heat extraction. | Lower cooling efficiency due to mixing with hot gas flow. |

| Complexity | Complex manufacturing due to intricate internal channels. | Simple to implement with drilled holes or slots. |

| Impact on Blade Durability | Enhances longevity by maintaining structural integrity. | Reduces oxidation and corrosion but may have erosion risk. |

| Typical Usage | Used in high-performance gas turbines and jet engines. | Common in turbine blades exposed to extreme thermal loads. |

Introduction to Turbine Blade Cooling Technologies

Turbine blade cooling technologies are critical for enhancing the durability and efficiency of gas turbine engines operating under extreme temperatures. Internal cooling methods, such as convective and impingement cooling, circulate air through intricate channels within the blade, while film cooling creates a protective layer of cooler air over the blade surface to shield it from hot gases. Advanced materials combined with these cooling techniques enable turbines to withstand temperatures exceeding the melting point of blade materials, improving performance and longevity.

Importance of Cooling in Gas Turbines

Effective cooling in gas turbines is essential to maintain blade integrity and prevent thermal fatigue caused by extreme operating temperatures exceeding 1,500degC. Turbine blade cooling methods, such as internal convective cooling and film cooling, provide critical temperature management to enhance blade durability and improve overall engine efficiency. Proper cooling extends component life, reduces maintenance costs, and allows turbines to achieve higher performance levels by operating safely under increased thermal loads.

Overview of Turbine Blade Cooling Methods

Turbine blade cooling methods primarily include internal cooling and film cooling techniques to manage extreme temperatures in gas turbines. Internal cooling circulates air through intricate channels inside the blade, enhancing heat dissipation by convection, while film cooling involves ejecting coolant through small holes to create a protective, insulating layer on the blade surface. Both methods are engineered to significantly extend blade life and improve turbine efficiency by reducing thermal stress and preventing material degradation.

What is Film Cooling?

Film cooling is a thermal protection technique used in gas turbine engines where a thin layer of coolant, usually air, is injected through small holes on the turbine blade surface to form a protective barrier between the hot gases and the blade metal. This cooling film reduces the blade temperature by insulating it from the high-temperature combustion gases, prolonging blade life and improving engine efficiency. Your turbine's performance benefits from film cooling by maintaining structural integrity under extreme operating conditions without compromising aerodynamic efficiency.

Working Principle of Turbine Blade Internal Cooling

Turbine blade internal cooling works by channeling cooler air through intricate internal passages within the blade, reducing its temperature and preventing thermal fatigue. This airflow absorbs heat from the blade material, maintaining structural integrity and enhancing engine efficiency. Your turbine's lifespan and performance depend heavily on the effectiveness of this internal cooling method compared to external film cooling techniques.

Comparative Thermal Performance: Turbine Blade Cooling vs Film Cooling

Turbine blade cooling techniques, including internal convective cooling, demonstrate higher thermal performance by maintaining blade material temperatures below critical limits through enhanced heat transfer inside cooling channels. Film cooling forms a protective coolant layer on the blade surface, reducing heat flux but often resulting in less efficient heat removal due to coolant mixing and surface temperature gradients. Comparative studies reveal turbine blade internal cooling achieves superior thermal protection and blade longevity under high thermal loads compared to film cooling, optimizing turbine efficiency and operational reliability.

Durability and Efficiency: Pros and Cons of Each Method

Turbine blade cooling using internal channels offers high durability by maintaining blade structural integrity under extreme temperatures, but often sacrifices some cooling efficiency due to limited heat dissipation. Film cooling enhances thermal efficiency by creating a protective coolant layer over the blade surface, though this can reduce durability as the coolant layer is prone to disruption from high-speed gas flow. Internal cooling systems provide longer blade life with moderate cooling, while film cooling maximizes thermal protection at the cost of potential blade erosion and maintenance challenges.

Recent Innovations in Turbine Blade and Film Cooling

Recent innovations in turbine blade cooling focus on advanced thermal barrier coatings combined with internal serpentine cooling channels that enhance heat dissipation in high-temperature environments. Film cooling improvements utilize multi-hole, angled injection patterns and nanostructured coatings to create more effective insulating air layers on blade surfaces, reducing thermal stress. These cutting-edge technologies optimize your turbine's efficiency and durability by significantly lowering operational temperatures and extending blade life cycles.

Application Areas and Industry Preferences

Turbine blade cooling and film cooling are critical techniques used predominantly in aerospace and power generation industries to manage extreme thermal stresses on turbine components. Turbine blade cooling, involving internal air channels, is preferred in high-performance jet engines for maximizing efficiency and durability under intense combustion temperatures. Film cooling creates a protective air layer on blade surfaces, favored in industrial gas turbines for ease of application and cost-effectiveness, helping you balance performance and maintenance in various operational environments.

Future Trends in Turbine Cooling Technologies

Future trends in turbine cooling technologies emphasize advanced additive manufacturing techniques to create complex internal cooling channels, significantly enhancing heat dissipation and structural integrity. Emerging film cooling methods leverage nanostructured coatings and optimized hole geometries to improve cooling air adherence and reduce thermal mixing with hot gases. Integration of smart sensors and adaptive cooling control systems aims to maximize efficiency while minimizing cooling air usage, crucial for next-generation high-performance gas turbines.

Turbine Blade Cooling vs Film Cooling Infographic

libmatt.com

libmatt.com