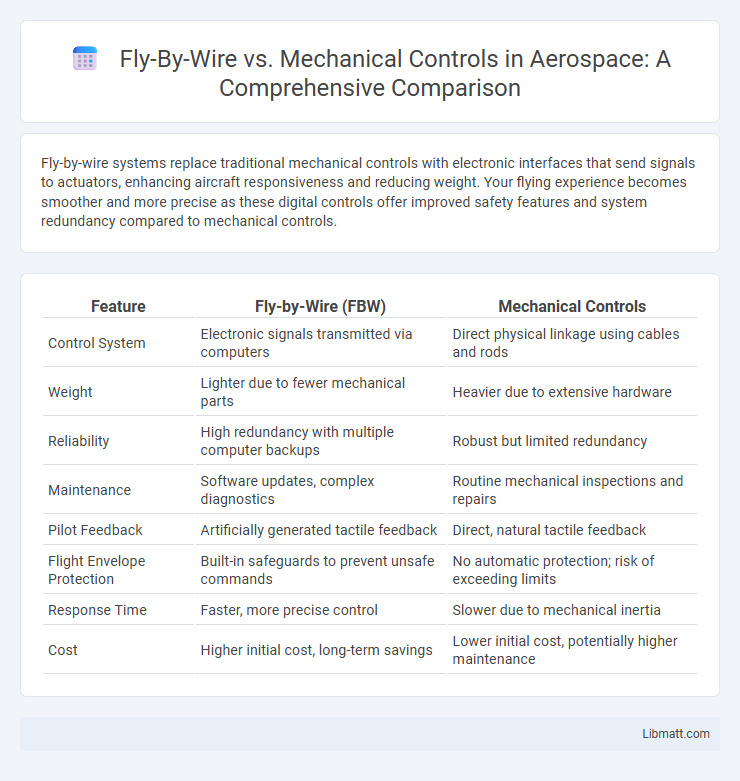

Fly-by-wire systems replace traditional mechanical controls with electronic interfaces that send signals to actuators, enhancing aircraft responsiveness and reducing weight. Your flying experience becomes smoother and more precise as these digital controls offer improved safety features and system redundancy compared to mechanical controls.

Table of Comparison

| Feature | Fly-by-Wire (FBW) | Mechanical Controls |

|---|---|---|

| Control System | Electronic signals transmitted via computers | Direct physical linkage using cables and rods |

| Weight | Lighter due to fewer mechanical parts | Heavier due to extensive hardware |

| Reliability | High redundancy with multiple computer backups | Robust but limited redundancy |

| Maintenance | Software updates, complex diagnostics | Routine mechanical inspections and repairs |

| Pilot Feedback | Artificially generated tactile feedback | Direct, natural tactile feedback |

| Flight Envelope Protection | Built-in safeguards to prevent unsafe commands | No automatic protection; risk of exceeding limits |

| Response Time | Faster, more precise control | Slower due to mechanical inertia |

| Cost | Higher initial cost, long-term savings | Lower initial cost, potentially higher maintenance |

Introduction to Aircraft Control Systems

Aircraft control systems consist of mechanical controls, which use direct physical linkages like cables and pulleys to manipulate control surfaces, and fly-by-wire systems, which replace these with electronic signals transmitted to actuators. Fly-by-wire technology enhances precision, reduces pilot workload, and improves safety by incorporating computer-assisted stability and control functions. Understanding the differences between these systems helps you evaluate modern aircraft designs in terms of reliability, maintainability, and performance.

What Is Fly-By-Wire?

Fly-by-wire is an advanced flight control system that replaces traditional mechanical linkages with electronic signals to operate an aircraft's control surfaces, enhancing precision and reducing weight. This system uses sensors, computers, and actuators to interpret pilot inputs and automatically adjust control surfaces for optimal performance and safety. Fly-by-wire systems improve your aircraft's responsiveness and allow for sophisticated automation that mechanical controls cannot achieve.

Understanding Mechanical Flight Controls

Mechanical flight controls rely on direct physical linkages such as cables, rods, and pulleys connecting the pilot's controls to the aircraft's control surfaces, ensuring immediate and tactile feedback during operation. These systems, used extensively in early aviation, require manual force to move control surfaces and provide pilots with intuitive control through mechanical advantage and aerodynamic loads. Understanding mechanical flight controls is essential for grasping the evolution of cockpit ergonomics and the transition towards digital fly-by-wire systems.

Key Differences Between Fly-By-Wire and Mechanical Controls

Fly-by-wire systems replace traditional mechanical linkages with electronic signals to control aircraft surfaces, enhancing precision and reducing weight. Mechanical controls rely on physical connections like cables and rods, offering direct pilot input but increased maintenance and slower response times. Fly-by-wire also integrates advanced computer algorithms for stability augmentation and safety features, which are absent in mechanical control systems.

Advantages of Fly-By-Wire Systems

Fly-by-wire systems enhance aircraft performance by replacing traditional mechanical controls with electronic signals, reducing weight and maintenance complexity. These systems improve safety through advanced flight envelope protection and automated error correction, minimizing pilot workload and increasing operational precision. Integration with modern avionics allows for adaptive control strategies, resulting in smoother handling and fuel efficiency enhancements.

Benefits of Mechanical Controls

Mechanical controls in aircraft provide direct tactile feedback, allowing pilots to feel aerodynamic forces and control surface resistance, which enhances situational awareness and precision during flight. These systems are inherently simple and reliable, reducing dependency on electrical power sources and minimizing the risk of system failure due to electronic malfunctions. Maintenance and troubleshooting are often more straightforward, making mechanical controls a durable and cost-effective choice in various aviation applications.

Limitations and Challenges of Each System

Mechanical control systems in aircraft face limitations such as increased weight, wear and tear from moving parts, and reduced responsiveness at high speeds due to aerodynamic forces on control surfaces. Fly-by-wire systems encounter challenges including reliance on complex software algorithms, vulnerability to electronic failures or cyber threats, and the need for redundant systems to ensure safety and reliability. Both systems must address maintenance demands and pilot adaptation to varying control feedback and behaviors.

Safety Considerations in Modern Aircraft

Fly-by-wire systems enhance aircraft safety by replacing mechanical linkages with electronic controls, allowing for real-time flight envelope protection and automated response to pilot inputs that reduce the risk of human error. These systems incorporate multiple redundant sensors and computers to ensure continuous operation even if one component fails, increasing overall reliability compared to traditional mechanical controls. Mechanical controls, while simpler and more intuitive, lack the advanced safety features and fail-safe mechanisms integral to fly-by-wire technology in modern commercial and military aircraft.

Industry Adoption and Notable Aircraft Examples

Fly-by-wire systems have seen widespread adoption in modern commercial and military aviation due to their enhanced safety, weight reduction, and improved aircraft handling capabilities. Notable aircraft featuring fly-by-wire include the Airbus A320, Boeing 777, and the F-16 Fighting Falcon, whereas older models like the Cessna 172 and Boeing 737 Classic maintain traditional mechanical control systems. Your choice between these systems impacts maintenance complexity and pilot interface, with fly-by-wire offering advanced automation and control precision.

Future Trends in Aircraft Control Technology

Fly-by-wire systems are increasingly integrated with advanced sensors and artificial intelligence to enhance aircraft responsiveness and safety while reducing pilot workload. Mechanical controls are gradually being replaced due to their higher weight and maintenance demands, as fly-by-wire enables more efficient and precise control through electronic signal transmission. Emerging trends include adaptive flight control systems and fault-tolerant architectures, which promise greater operational reliability and optimized flight performance in next-generation aircraft.

fly-by-wire vs mechanical controls Infographic

libmatt.com

libmatt.com