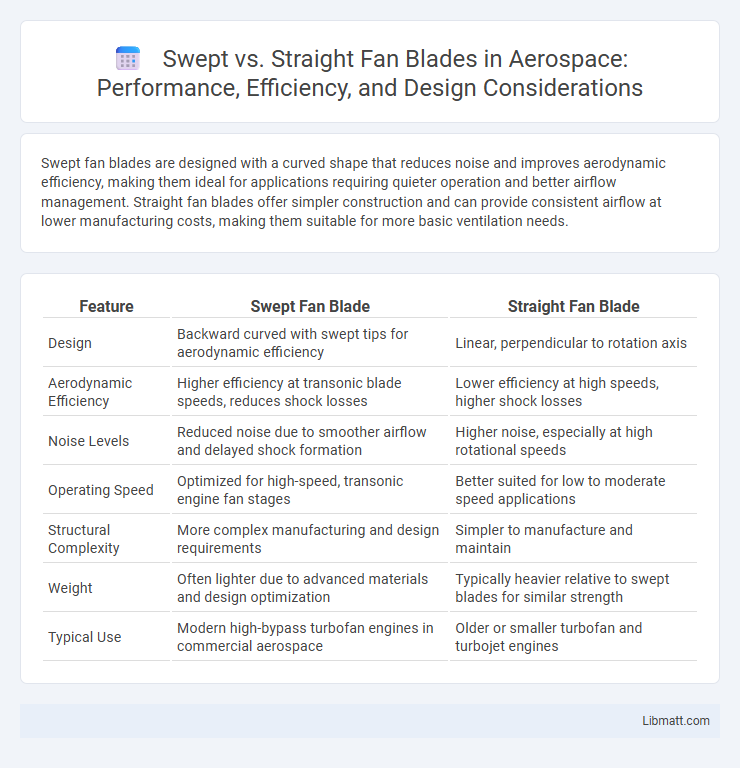

Swept fan blades are designed with a curved shape that reduces noise and improves aerodynamic efficiency, making them ideal for applications requiring quieter operation and better airflow management. Straight fan blades offer simpler construction and can provide consistent airflow at lower manufacturing costs, making them suitable for more basic ventilation needs.

Table of Comparison

| Feature | Swept Fan Blade | Straight Fan Blade |

|---|---|---|

| Design | Backward curved with swept tips for aerodynamic efficiency | Linear, perpendicular to rotation axis |

| Aerodynamic Efficiency | Higher efficiency at transonic blade speeds, reduces shock losses | Lower efficiency at high speeds, higher shock losses |

| Noise Levels | Reduced noise due to smoother airflow and delayed shock formation | Higher noise, especially at high rotational speeds |

| Operating Speed | Optimized for high-speed, transonic engine fan stages | Better suited for low to moderate speed applications |

| Structural Complexity | More complex manufacturing and design requirements | Simpler to manufacture and maintain |

| Weight | Often lighter due to advanced materials and design optimization | Typically heavier relative to swept blades for similar strength |

| Typical Use | Modern high-bypass turbofan engines in commercial aerospace | Older or smaller turbofan and turbojet engines |

Introduction to Fan Blade Designs

Swept fan blades feature a curved, aerodynamic shape that reduces noise and improves efficiency by minimizing shock waves and turbulence. Straight fan blades offer a simpler design with easier manufacturing and consistent airflow but generally generate higher noise levels and less aerodynamic efficiency. The choice between swept and straight fan blades depends on balancing noise reduction, performance demands, and manufacturing complexity in applications such as aviation, HVAC, and industrial fans.

What Are Straight Fan Blades?

Straight fan blades feature a linear design extending directly from the hub without curvature, optimizing airflow efficiency at lower noise levels. These blades are commonly used in HVAC systems and cooling fans where consistent, steady airflow is necessary. Your choice of straight fan blades can improve energy efficiency and reduce operational noise in various applications.

What Are Swept Fan Blades?

Swept fan blades are aerodynamically curved blades designed to reduce noise and improve efficiency by minimizing airflow turbulence and drag. Unlike straight fan blades, which have a simple linear shape, swept blades mimic the swept wing design of aircraft, allowing for smoother air passage and enhanced pressure distribution. Your HVAC system or computer cooling setup can benefit from swept fan blades through quieter operation and increased airflow performance.

Aerodynamic Principles Behind Blade Shapes

Swept fan blades reduce shock waves and delay compressibility effects at high rotational speeds, improving aerodynamic efficiency by minimizing drag and noise compared to straight fan blades. Straight blades generate more uniform airflow but are prone to higher pressure losses and increased turbulence due to abrupt flow changes. Understanding these aerodynamic principles helps optimize your fan blade selection for enhanced performance and energy efficiency in various applications.

Efficiency Comparison: Swept vs Straight

Swept fan blades typically offer higher aerodynamic efficiency than straight fan blades by reducing shock losses at high rotational speeds and improving pressure distribution along the blade surface. The curved geometry of swept blades minimizes flow separation and delays the onset of stall, resulting in smoother airflow and enhanced overall performance. In contrast, straight fan blades generate more turbulence and noise, leading to lower efficiency, especially in high-speed applications.

Noise Levels: Which Design Is Quieter?

Swept fan blades generate less noise compared to straight fan blades due to their aerodynamic shape, which reduces turbulence and airflow separation. The curved design smooths the airflow, resulting in quieter operation, making them ideal for environments where noise reduction is a priority. If you prioritize a quieter fan, selecting a model with swept blades can significantly enhance your comfort by minimizing disruptive sound levels.

Structural Durability and Wear

Swept fan blades exhibit enhanced structural durability due to their aerodynamic design, which reduces stress concentration and minimizes fatigue over extended operation. Their curvature allows for better load distribution, decreasing wear compared to straight fan blades that experience higher localized stresses and increased vibration. Consequently, swept blades typically achieve longer service life and lower maintenance requirements in high-performance environments.

Applications in Industry and Everyday Appliances

Swept fan blades are commonly used in aerospace and HVAC systems due to their higher aerodynamic efficiency, reduced noise, and improved performance at high speeds. Straight fan blades are prevalent in household appliances like ceiling fans, exhaust fans, and cooling devices because of their simple design, ease of manufacturing, and effectiveness at lower rotational speeds. Industrial applications benefit from swept blades in turbines and compressors where energy efficiency and noise reduction are critical, while straight blades dominate applications requiring durability and straightforward maintenance.

Cost Implications and Manufacturing Complexity

Swept fan blades generally incur higher manufacturing costs compared to straight fan blades due to their complex aerodynamic design requiring precise curvature and advanced materials, which increases machining time and tooling expenses. Straight fan blades have simpler geometry, enabling easier mass production with lower tooling costs and reduced labor, making them more cost-effective for standard applications. The increased manufacturing complexity of swept blades can drive up initial investment but offers improved performance in fuel efficiency, potentially offsetting costs over time.

Choosing the Right Fan Blade for Your Needs

Swept fan blades offer enhanced aerodynamic efficiency by reducing noise and improving airflow, making them ideal for environments requiring quiet and energy-efficient performance. Straight fan blades provide robust airflow and are typically easier to manufacture, making them cost-effective for applications where noise is less of a concern. Selecting the right fan blade depends on balancing noise reduction, airflow requirements, and budget constraints to optimize performance for your specific needs.

swept fan blade vs straight fan blade Infographic

libmatt.com

libmatt.com