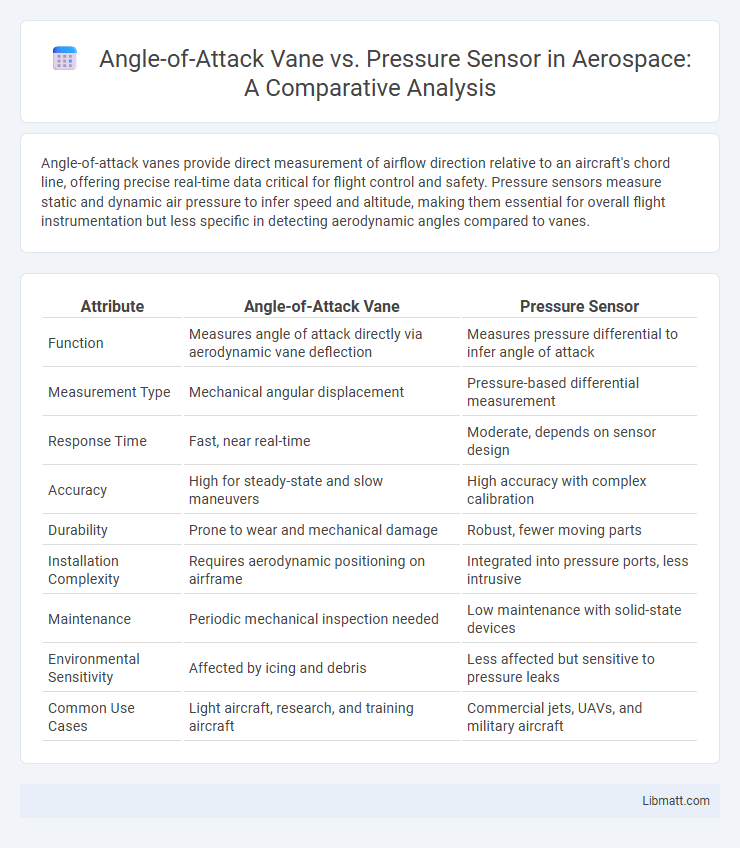

Angle-of-attack vanes provide direct measurement of airflow direction relative to an aircraft's chord line, offering precise real-time data critical for flight control and safety. Pressure sensors measure static and dynamic air pressure to infer speed and altitude, making them essential for overall flight instrumentation but less specific in detecting aerodynamic angles compared to vanes.

Table of Comparison

| Attribute | Angle-of-Attack Vane | Pressure Sensor |

|---|---|---|

| Function | Measures angle of attack directly via aerodynamic vane deflection | Measures pressure differential to infer angle of attack |

| Measurement Type | Mechanical angular displacement | Pressure-based differential measurement |

| Response Time | Fast, near real-time | Moderate, depends on sensor design |

| Accuracy | High for steady-state and slow maneuvers | High accuracy with complex calibration |

| Durability | Prone to wear and mechanical damage | Robust, fewer moving parts |

| Installation Complexity | Requires aerodynamic positioning on airframe | Integrated into pressure ports, less intrusive |

| Maintenance | Periodic mechanical inspection needed | Low maintenance with solid-state devices |

| Environmental Sensitivity | Affected by icing and debris | Less affected but sensitive to pressure leaks |

| Common Use Cases | Light aircraft, research, and training aircraft | Commercial jets, UAVs, and military aircraft |

Introduction: Understanding Angle-of-Attack Measurement

Angle-of-attack vanes provide direct mechanical measurement by physically detecting airflow direction relative to the aircraft's chord line, offering high accuracy in dynamic conditions. Pressure sensors measure differential air pressure on the aircraft surface to infer angle-of-attack, enabling integration with existing pitot-static systems and reducing mechanical complexity. Each method impacts system responsiveness and maintenance, with vanes excelling in precision and pressure sensors favoring durability and integration.

What is an Angle-of-Attack Vane?

An angle-of-attack vane is a sensor device that measures the angle between the relative airflow and a reference line on an aircraft wing or control surface, providing critical data for aerodynamic performance and stability. Unlike pressure sensors that detect static and dynamic air pressure to infer flight conditions, the vane directly captures the angle of attack, offering real-time accuracy essential for flight control systems. Your aircraft's safety and efficiency depend on precise angle-of-attack measurements, making the vane a key component in preventing stalls and optimizing maneuverability.

Overview of Pressure-Based Sensors

Pressure-based sensors measure angle of attack by detecting differential pressure across strategically placed ports on an aircraft's surface, providing real-time aerodynamic data critical for flight control systems. These sensors are highly reliable due to their direct measurement of airflow pressure variations, enabling precise calculation of the angle of attack without moving parts. Their compact design and ability to integrate seamlessly with avionics systems make them a preferred choice for modern aircraft performance monitoring and safety enhancements.

Principles of Operation: Vane vs Pressure Sensor

An angle-of-attack vane measures the airflow direction by physically aligning with the relative wind, providing direct mechanical deflection data correlated to the angle of attack. Pressure sensors determine the angle of attack indirectly by comparing differential pressures between ports strategically placed on the aircraft's surface, translating pressure differences into aerodynamic angle measurements. The vane's principle relies on physical displacement, while pressure sensors use pneumatic pressure variations to infer the angle of attack.

Accuracy and Reliability Comparison

Angle-of-attack vanes provide direct measurement of airflow angle, offering high accuracy under stable conditions but are susceptible to mechanical wear and environmental contamination, which can affect long-term reliability. Pressure sensors infer angle-of-attack by measuring differential pressure, delivering consistent performance with fewer moving parts and greater resistance to environmental factors, enhancing reliability in varied flight scenarios. Your choice depends on the required precision and operational environment, where pressure sensors often excel in reliability, and vanes may offer superior instantaneous accuracy.

Response Time and Sensitivity

Angle-of-attack vanes offer rapid response times as they directly measure the airflow angle through mechanical deflection, enabling immediate aerodynamic data critical for flight control systems. Pressure sensors detect angle-of-attack indirectly by measuring differential pressure across surfaces, resulting in slightly slower response times due to fluid dynamics effects but enhanced sensitivity to subtle airflow variations. Sensitivity in vanes depends on mechanical precision and alignment, while pressure sensors provide higher sensitivity in low-speed regimes where pressure differences are minimal, making each technology optimal for specific operational contexts.

Installation and Maintenance Requirements

An angle-of-attack vane requires precise mechanical alignment during installation to ensure accurate measurements, often demanding specialized tools and expert calibration. In contrast, pressure sensors are typically easier to install with fewer mechanical constraints, relying on proper placement within the airflow path and secure electrical connections. Your maintenance routine for angle-of-attack vanes involves regular inspection for physical damage and lubrication of moving parts, whereas pressure sensors primarily need periodic checks for contamination and calibration verification.

Impact on Aircraft Performance and Safety

Angle-of-attack vanes provide direct measurement of airflow angle, enabling precise control of lift and stall prevention, thus enhancing aircraft performance and safety. Pressure sensors infer angle-of-attack indirectly through pressure differences, offering redundancy but sometimes less accuracy in turbulent conditions, potentially impacting reliability. Integrating both systems improves situational awareness, reducing stall risk and optimizing aerodynamic efficiency for safer flight operations.

Cost Analysis and Practical Considerations

Angle-of-attack vanes generally offer lower upfront costs compared to pressure sensors due to simpler mechanical design and fewer electronic components. Maintenance expenses tend to be higher for vanes because moving parts are prone to wear, while pressure sensors benefit from solid-state durability, reducing long-term servicing. Practical considerations include sensitivity to environmental factors: vanes can be affected by ice and debris, whereas pressure sensors require careful installation for accurate differential pressure measurement.

Choosing the Right System for Your Application

Selecting the appropriate angle-of-attack measurement system depends on your application's specific accuracy, response time, and environmental conditions. Angle-of-attack vanes provide direct, real-time airflow angle data with high precision, ideal for aerodynamic testing and aircraft control systems. Pressure sensors, while generally more robust and less prone to mechanical failure, infer angle indirectly through differential pressure measurements and are better suited for applications requiring durability and low maintenance.

angle-of-attack vane vs pressure sensor Infographic

libmatt.com

libmatt.com