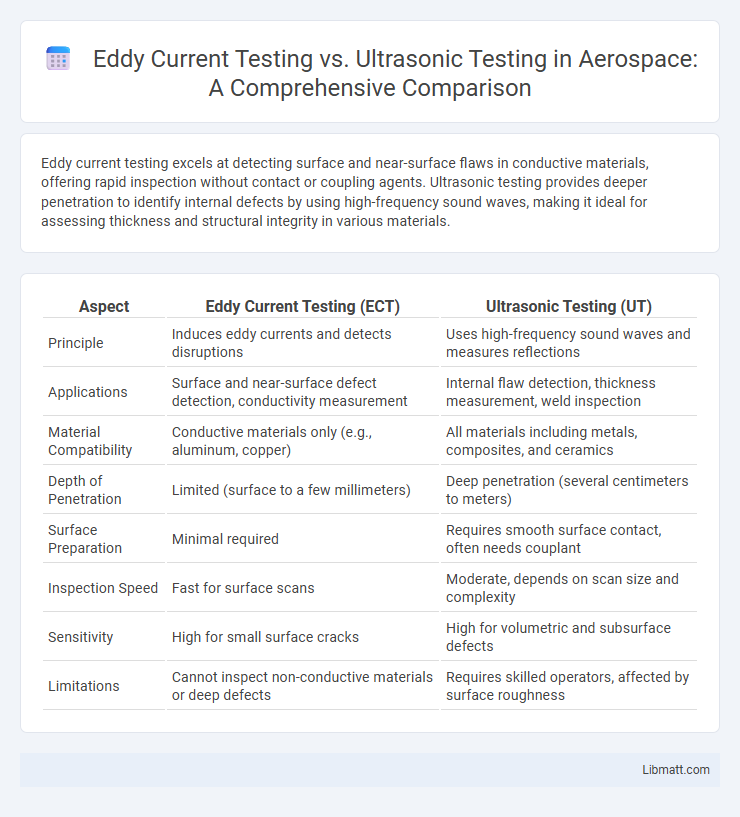

Eddy current testing excels at detecting surface and near-surface flaws in conductive materials, offering rapid inspection without contact or coupling agents. Ultrasonic testing provides deeper penetration to identify internal defects by using high-frequency sound waves, making it ideal for assessing thickness and structural integrity in various materials.

Table of Comparison

| Aspect | Eddy Current Testing (ECT) | Ultrasonic Testing (UT) |

|---|---|---|

| Principle | Induces eddy currents and detects disruptions | Uses high-frequency sound waves and measures reflections |

| Applications | Surface and near-surface defect detection, conductivity measurement | Internal flaw detection, thickness measurement, weld inspection |

| Material Compatibility | Conductive materials only (e.g., aluminum, copper) | All materials including metals, composites, and ceramics |

| Depth of Penetration | Limited (surface to a few millimeters) | Deep penetration (several centimeters to meters) |

| Surface Preparation | Minimal required | Requires smooth surface contact, often needs couplant |

| Inspection Speed | Fast for surface scans | Moderate, depends on scan size and complexity |

| Sensitivity | High for small surface cracks | High for volumetric and subsurface defects |

| Limitations | Cannot inspect non-conductive materials or deep defects | Requires skilled operators, affected by surface roughness |

Introduction to Non-Destructive Testing Methods

Eddy current testing and ultrasonic testing are essential non-destructive testing (NDT) methods used to inspect the integrity of materials without causing damage. Eddy current testing utilizes electromagnetic induction to detect surface and near-surface flaws, making it ideal for conductive materials, while ultrasonic testing employs high-frequency sound waves to reveal internal defects and measure thickness. Choosing the right method depends on your specific inspection needs, including material type, defect location, and required sensitivity.

What is Eddy Current Testing?

Eddy Current Testing (ECT) is a nondestructive testing method that employs electromagnetic induction to detect surface and near-surface defects in conductive materials. By inducing circulating electrical currents called eddy currents in the test object, changes in conductivity and permeability are measured to identify flaws such as cracks, corrosion, or material thickness variations. ECT is widely used in industries like aerospace, manufacturing, and power generation for rapid, precise inspection without requiring direct contact or surface preparation.

What is Ultrasonic Testing?

Ultrasonic Testing (UT) is a nondestructive testing method that uses high-frequency sound waves to detect internal flaws or characterize materials. It sends ultrasonic pulses into a material and measures the reflected signals to identify discontinuities or thickness variations. Your inspection benefits from UT's ability to provide precise depth information and high sensitivity for detecting cracks, corrosion, and other subsurface defects.

Principles and Working Mechanisms

Eddy current testing operates on electromagnetic induction principles, where alternating current in a coil generates a magnetic field that induces eddy currents in conductive materials, detecting flaws by changes in impedance. Ultrasonic testing uses high-frequency sound waves transmitted into a material, reflecting back from internal features to identify defects based on time-of-flight and amplitude changes. Understanding these working mechanisms helps you select the appropriate nondestructive testing technique for material inspection.

Key Differences Between Eddy Current and Ultrasonic Testing

Eddy current testing uses electromagnetic induction to detect surface and near-surface defects in conductive materials, while ultrasonic testing employs high-frequency sound waves to identify internal flaws and measure material thickness. Eddy current testing is ideal for inspecting non-ferrous metals and detecting cracks, corrosion, and other surface irregularities, whereas ultrasonic testing excels at evaluating welds, measuring material thickness, and detecting subsurface defects in a wide range of materials. The penetration depth of ultrasonic testing surpasses that of eddy current testing, making it suitable for thicker components and complex geometries.

Applications in Various Industries

Eddy current testing is widely applied in aerospace, automotive, and manufacturing industries for detecting surface cracks, corrosion, and material thickness variations in conductive materials. Ultrasonic testing excels in oil and gas, power generation, and construction sectors by providing detailed internal flaw detection and thickness measurements in metals, composites, and welds. Your choice between these methods depends on the specific material properties and inspection requirements within your industry.

Advantages of Eddy Current Testing

Eddy Current Testing offers high sensitivity to surface and near-surface defects in conductive materials, making it ideal for detecting cracks, corrosion, and other imperfections without causing damage. Its rapid inspection capability and minimal preparation requirements reduce downtime, allowing efficient evaluation of complex geometries and layered structures. You benefit from precise flaw characterization and real-time results, enhancing maintenance and quality control processes compared to Ultrasonic Testing.

Advantages of Ultrasonic Testing

Ultrasonic testing offers superior depth penetration and accuracy for detecting internal flaws in various materials, including metals, composites, and welds, making it ideal for critical structural inspections. Its ability to generate detailed cross-sectional images allows precise measurement of flaw size and location, which is often unattainable with eddy current testing. Your inspection process benefits from ultrasonic testing's adaptability to different material types and thicknesses, enhancing reliability in safety-critical applications.

Limitations and Challenges

Eddy current testing faces limitations in detecting defects beneath non-conductive coatings and struggles with complex geometries due to its shallow penetration depth. Ultrasonic testing encounters challenges with surface roughness and requires skilled operators to interpret signals accurately, especially in materials with coarse grain structures. Your choice between these methods depends on the material properties and inspection requirements, balancing depth of penetration against sensitivity to surface conditions.

Choosing the Right Method for Your Inspection Needs

Eddy current testing excels in detecting surface and near-surface defects in conductive materials with high sensitivity and rapid results, making it ideal for inspecting complex geometries and thin structures. Ultrasonic testing penetrates deeper into materials, providing precise volumetric defect characterization and thickness measurements, suitable for thick metals and weld inspections. Selecting between these methods depends on the material type, defect location, inspection speed requirements, and the specific sensitivity needed for accurate flaw detection.

eddy current testing vs ultrasonic testing Infographic

libmatt.com

libmatt.com