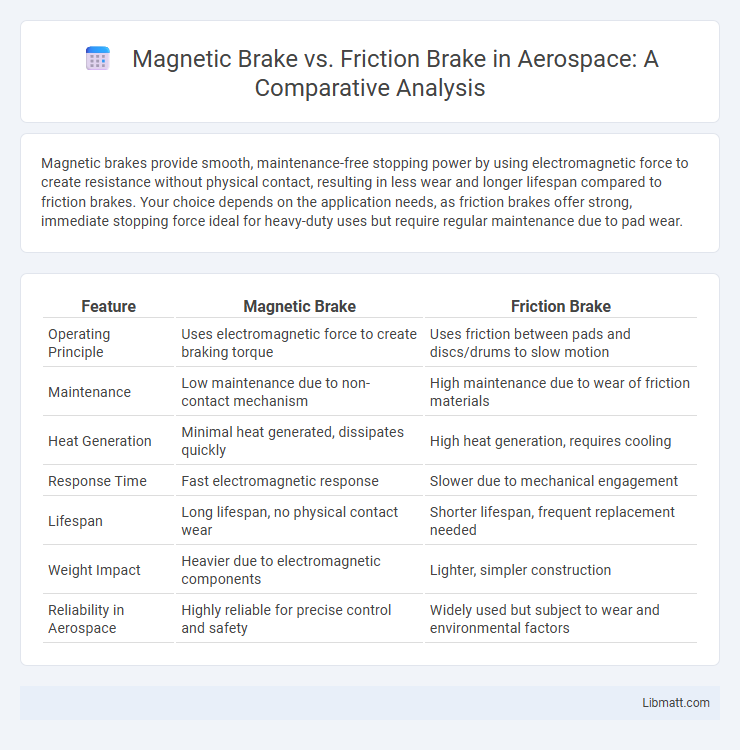

Magnetic brakes provide smooth, maintenance-free stopping power by using electromagnetic force to create resistance without physical contact, resulting in less wear and longer lifespan compared to friction brakes. Your choice depends on the application needs, as friction brakes offer strong, immediate stopping force ideal for heavy-duty uses but require regular maintenance due to pad wear.

Table of Comparison

| Feature | Magnetic Brake | Friction Brake |

|---|---|---|

| Operating Principle | Uses electromagnetic force to create braking torque | Uses friction between pads and discs/drums to slow motion |

| Maintenance | Low maintenance due to non-contact mechanism | High maintenance due to wear of friction materials |

| Heat Generation | Minimal heat generated, dissipates quickly | High heat generation, requires cooling |

| Response Time | Fast electromagnetic response | Slower due to mechanical engagement |

| Lifespan | Long lifespan, no physical contact wear | Shorter lifespan, frequent replacement needed |

| Weight Impact | Heavier due to electromagnetic components | Lighter, simpler construction |

| Reliability in Aerospace | Highly reliable for precise control and safety | Widely used but subject to wear and environmental factors |

Introduction to Magnetic Brakes and Friction Brakes

Magnetic brakes use electromagnetic force to create resistance without physical contact, resulting in less wear and quieter operation. Friction brakes rely on direct contact between brake pads and a rotor or drum, generating heat to slow or stop motion. Your choice depends on application needs, with magnetic brakes offering smoother performance and friction brakes providing robust stopping power.

How Magnetic Brakes Work

Magnetic brakes operate by using electromagnetic force to create resistance without physical contact, generating eddy currents that oppose motion and produce a smooth, wear-free braking effect. Unlike friction brakes, which rely on brake pads pressing against a rotor to create friction, magnetic brakes provide consistent deceleration with minimal maintenance due to the absence of mechanical wear. This system is commonly applied in trains, roller coasters, and industrial machinery where durability and silent operation are critical.

How Friction Brakes Work

Friction brakes operate by applying pressure to a rotating surface using brake pads or shoes, generating friction that slows or stops motion. The brake pads press against a drum or disc connected to the wheel or machinery, converting kinetic energy into heat energy through friction. This mechanical process ensures controlled deceleration and is widely used in automotive and industrial braking systems.

Key Components of Each Brake System

Magnetic brakes utilize key components such as electromagnets, armatures, and conductive discs or rotors to generate eddy currents that provide non-contact braking force. Friction brakes consist primarily of pads or shoes made of high-friction materials, brake rotors or drums, and hydraulic or mechanical actuators that create contact and resistance to slow down motion. Each system's design focuses on either electromagnetic induction for wear-free braking or direct surface contact for effective stopping power.

Performance Comparison: Stopping Power

Magnetic brakes provide consistent stopping power by using electromagnetic force, which generates less wear and offers smoother deceleration compared to friction brakes. Friction brakes rely on physical contact between brake pads and rotors, delivering strong initial stopping power but are prone to heat buildup and performance degradation under heavy use. Magnetic brake systems excel in applications requiring precise control and low maintenance, while friction brakes remain effective for high-force, short-duration stops.

Durability and Maintenance Needs

Magnetic brakes offer superior durability compared to friction brakes due to their non-contact operation, which minimizes wear and tear on components. Friction brakes require frequent maintenance and replacement of brake pads or liners because of consistent material abrasion during use. You can reduce downtime and long-term maintenance costs by choosing magnetic brakes for applications demanding reliable, low-maintenance braking solutions.

Safety Considerations

Magnetic brakes offer enhanced safety by providing consistent, wear-free stopping power that reduces the risk of brake fade under high temperatures. Friction brakes rely on physical contact, which can deteriorate over time and may lead to decreased performance or failure if not properly maintained. Your choice should factor in the operating environment, as magnetic brakes deliver reliable and maintenance-free safety, especially in high-demand applications.

Cost Analysis: Installation and Upkeep

Magnetic brakes generally require a higher initial installation cost due to advanced components and technology, whereas friction brakes are more affordable and widely available. Maintenance expenses for magnetic brakes are lower because they experience less wear and tear, while friction brakes need frequent replacement of pads and discs. Choosing your braking system depends on balancing upfront investment with long-term upkeep efficiency.

Ideal Applications for Each Brake Type

Magnetic brakes excel in applications requiring precise speed control and low maintenance, such as industrial conveyors, electric trains, and robotics, due to their smooth, contactless operation. Friction brakes are ideal for vehicles, heavy machinery, and emergency stopping systems where high force and reliable stopping power are crucial. Your choice depends on whether you prioritize continuous, wear-free braking or high-torque, reliable stopping performance.

Conclusion: Choosing the Right Brake System

Magnetic brakes offer superior durability and low maintenance due to their contactless operation, making them ideal for applications requiring high precision and frequent use. Friction brakes provide strong stopping power and cost-effective installation, suitable for heavy-duty tasks and environments with limited budget constraints. Selecting the right brake system depends on specific requirements such as load capacity, operational frequency, maintenance capabilities, and budget considerations.

magnetic brake vs friction brake Infographic

libmatt.com

libmatt.com