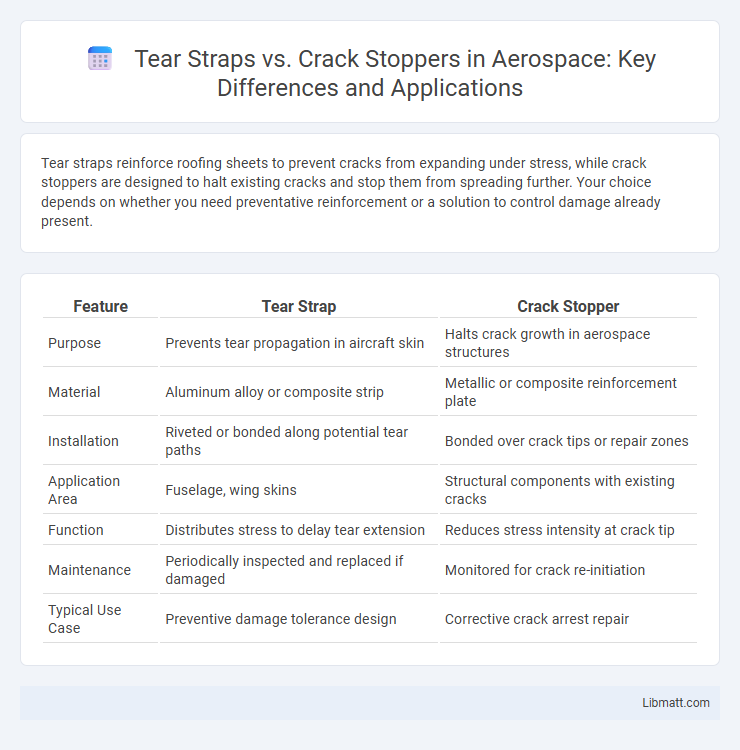

Tear straps reinforce roofing sheets to prevent cracks from expanding under stress, while crack stoppers are designed to halt existing cracks and stop them from spreading further. Your choice depends on whether you need preventative reinforcement or a solution to control damage already present.

Table of Comparison

| Feature | Tear Strap | Crack Stopper |

|---|---|---|

| Purpose | Prevents tear propagation in aircraft skin | Halts crack growth in aerospace structures |

| Material | Aluminum alloy or composite strip | Metallic or composite reinforcement plate |

| Installation | Riveted or bonded along potential tear paths | Bonded over crack tips or repair zones |

| Application Area | Fuselage, wing skins | Structural components with existing cracks |

| Function | Distributes stress to delay tear extension | Reduces stress intensity at crack tip |

| Maintenance | Periodically inspected and replaced if damaged | Monitored for crack re-initiation |

| Typical Use Case | Preventive damage tolerance design | Corrective crack arrest repair |

Introduction to Tear Straps and Crack Stoppers

Tear straps and crack stoppers are essential reinforcement materials used in asphalt pavement to control and prevent cracks. Tear straps are narrow strips embedded within the pavement layers to distribute stresses and limit crack propagation, enhancing durability. Crack stoppers are specialized membranes or fabric layers applied to halt existing cracks from expanding, protecting your pavement investment from further damage.

Definition and Purpose of Tear Straps

Tear straps are reinforced metal plates attached to the hull of a ship to prevent the propagation of cracks caused by structural failure or impact, thereby enhancing the vessel's overall integrity. Their primary purpose is to arrest the spread of cracks in the ship's plating, reducing the risk of catastrophic structural failure during harsh sea conditions or collisions. Unlike crack stoppers that focus on localized crack halting, tear straps provide continuous reinforcement along critical hull sections to maintain hull strength and safety.

Definition and Role of Crack Stoppers

Crack stoppers are specially designed components used in construction to prevent the propagation of cracks in concrete or masonry structures, thereby enhancing durability and structural integrity. Unlike tear straps, which primarily provide tensile reinforcement and resist separation along joints or seams, crack stoppers absorb and distribute stress concentrations to halt crack development. Their role is critical in maintaining long-term stability by mitigating damage caused by environmental stressors and load variations.

Key Differences Between Tear Straps and Crack Stoppers

Tear straps are steel reinforcements installed across pavement cracks to prevent reflective cracking caused by temperature changes or heavy traffic loads. Crack stoppers, typically made of rubberized or polymer materials, serve as flexible barriers that halt existing crack propagation and minimize pavement deterioration. The key difference lies in their function: tear straps provide structural strength to resist new cracks, whereas crack stoppers focus on sealing and controlling the expansion of current cracks.

Applications in Aerospace Structures

Tear straps and crack stoppers are critical reinforcements in aerospace structures designed to manage stress and prevent crack propagation under cyclic loading conditions. Tear straps are often used to enhance the durability of fuselage panels by redistributing stress around damage sites, while crack stoppers serve as barriers that arrest crack growth in wing skins and other critical load-bearing components. Your aerospace engineering projects benefit from integrating these elements to improve structural integrity and extend service life.

Material Selection for Tear Straps and Crack Stoppers

Tear straps are typically made from high-strength, abrasion-resistant steel or synthetic composites designed to reinforce joints and prevent crack propagation in concrete or asphalt surfaces. Crack stoppers use flexible, durable rubber or elastomeric materials that absorb and accommodate movement, controlling crack width and minimizing pavement distress. Selecting the appropriate material depends on your project's load conditions, environmental exposure, and long-term durability requirements.

Installation Techniques and Best Practices

Tear straps require precise alignment along joint edges and are typically installed using mechanical fastening or adhesive bonding for optimal reinforcement. Crack stoppers are embedded in cracks via injection or epoxy filling, sealing and preventing further propagation while maintaining structural integrity. Best practices emphasize surface preparation, moisture control, and adherence to manufacturer specifications to ensure long-lasting performance and durability.

Advantages and Limitations of Tear Straps

Tear straps offer enhanced resistance against crack propagation in asphalt pavements by effectively arresting cracks and reducing maintenance frequency, which extends pavement lifespan and improves road safety. However, their installation can be labor-intensive and costly, requiring precise placement to ensure optimal performance, and they may be less effective in areas with extremely high traffic loads or severe environmental conditions. Despite these limitations, tear straps provide a durable solution that minimizes structural failures and supports overall pavement integrity compared to crack stoppers.

Pros and Cons of Crack Stoppers

Crack stoppers effectively prevent cracks from extending in walls and ceilings by reinforcing vulnerable areas with a flexible material, offering long-term protection against structural damage. They are easy to apply and cost-efficient, but may be less durable in high-impact zones and can sometimes peel or fail if not installed correctly. Your choice should consider the specific nature of the damage and whether flexibility or rigidity is more crucial for the repair.

Choosing Between Tear Straps and Crack Stoppers

Choosing between tear straps and crack stoppers depends on the specific structural needs of your project, as tear straps are designed to reinforce and prevent further tearing in materials subjected to high stress, while crack stoppers halt the propagation of existing cracks to maintain material integrity. Understanding the load requirements and type of damage is crucial; tear straps offer enhanced reinforcement for dynamic stresses, whereas crack stoppers provide localized repair for static or gradually expanding cracks. Selecting the appropriate solution ensures durability and safety in construction or repair applications, optimizing performance based on your project's conditions.

Tear strap vs Crack stopper Infographic

libmatt.com

libmatt.com