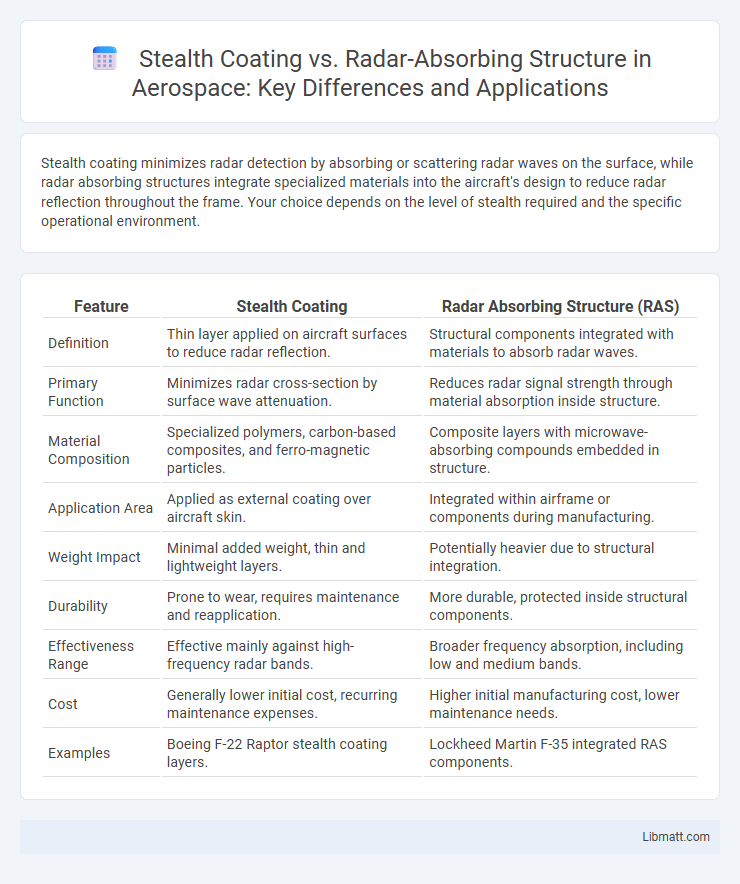

Stealth coating minimizes radar detection by absorbing or scattering radar waves on the surface, while radar absorbing structures integrate specialized materials into the aircraft's design to reduce radar reflection throughout the frame. Your choice depends on the level of stealth required and the specific operational environment.

Table of Comparison

| Feature | Stealth Coating | Radar Absorbing Structure (RAS) |

|---|---|---|

| Definition | Thin layer applied on aircraft surfaces to reduce radar reflection. | Structural components integrated with materials to absorb radar waves. |

| Primary Function | Minimizes radar cross-section by surface wave attenuation. | Reduces radar signal strength through material absorption inside structure. |

| Material Composition | Specialized polymers, carbon-based composites, and ferro-magnetic particles. | Composite layers with microwave-absorbing compounds embedded in structure. |

| Application Area | Applied as external coating over aircraft skin. | Integrated within airframe or components during manufacturing. |

| Weight Impact | Minimal added weight, thin and lightweight layers. | Potentially heavier due to structural integration. |

| Durability | Prone to wear, requires maintenance and reapplication. | More durable, protected inside structural components. |

| Effectiveness Range | Effective mainly against high-frequency radar bands. | Broader frequency absorption, including low and medium bands. |

| Cost | Generally lower initial cost, recurring maintenance expenses. | Higher initial manufacturing cost, lower maintenance needs. |

| Examples | Boeing F-22 Raptor stealth coating layers. | Lockheed Martin F-35 integrated RAS components. |

Introduction to Stealth Technology

Stealth technology enhances the survivability of aircraft by reducing their radar cross-section using methods such as stealth coating and radar absorbing structures (RAS). Stealth coating involves specialized materials applied to surfaces to absorb or scatter radar waves, while radar absorbing structures integrate radar-elusive design directly into the aircraft's form. Understanding the differences in these technologies helps improve your knowledge of how modern military aircraft achieve low observability.

What is Stealth Coating?

Stealth coating is a specialized material applied to aircraft, ships, or vehicles designed to absorb or scatter radar waves, significantly reducing their radar cross-section (RCS) and enhancing stealth capabilities. These coatings typically consist of radar-absorbing materials (RAM) that convert electromagnetic energy into heat, minimizing radar signal reflections. Unlike radar absorbing structures that integrate stealth features into the object's shape, stealth coatings provide an external layer optimizing radar evasion without altering the vehicle's design.

Understanding Radar Absorbing Structures (RAS)

Radar Absorbing Structures (RAS) are engineered materials designed to minimize radar wave reflection by absorbing electromagnetic energy, thereby reducing the radar cross-section of an object. Unlike stealth coatings that primarily provide a thin surface layer of absorption, RAS integrates absorbing materials directly into the structural components, enhancing durability and effectiveness across a broader frequency range. This integration improves stealth capabilities in military applications by ensuring consistent radar wave attenuation through the aircraft or vehicle's physical framework.

Key Differences: Coating vs. Structure

Stealth coating uses specialized materials applied as a thin layer on the surface of an aircraft to absorb or deflect radar waves, reducing its radar cross-section (RCS) without altering the structural design. Radar absorbing structures (RAS) are integrated into the aircraft's design, using shape and materials within the airframe to scatter or absorb radar energy more effectively over a wider range of angles and frequencies. Your choice between stealth coating and radar absorbing structure depends on factors like operational requirements, maintenance complexity, and desired stealth performance.

Materials Used in Stealth Coatings

Stealth coatings typically utilize specialized materials such as carbon-based polymers, ferrites, and conductive ceramics designed to absorb radar waves and reduce reflection. These materials work by converting radar energy into heat or dispersing the waves, thereby minimizing the aircraft's radar signature. Your understanding of stealth technology benefits from knowing that these coatings differ fundamentally from radar absorbing structures, which rely on geometric design alongside material properties.

Design Principles of Radar Absorbing Structures

Radar Absorbing Structures (RAS) employ advanced materials engineered to trap and dissipate electromagnetic waves, reducing radar signature by converting radar energy into heat. These structures utilize layered composites with specific dielectric and magnetic properties tailored to target frequencies for optimal absorption. The design integrates impedance matching and surface geometry to minimize reflection and enhance stealth performance in various operational environments.

Effectiveness Against Modern Radar Systems

Stealth Coating uses radar-absorbent materials to reduce radar signal reflections, effectively minimizing aircraft detectability by modern radar systems operating in multiple frequency bands. Radar Absorbing Structures integrate these materials into the aircraft's physical design, enhancing stealth by disrupting electromagnetic wave propagation and scattering radar signals. Modern radars with advanced frequency agility and polarization sensitivity challenge the effectiveness of both methods, requiring continuous innovation in coating compositions and structural designs.

Advantages and Limitations of Stealth Coating

Stealth coating offers significant advantages by absorbing radar waves, reducing the radar cross-section, and enhancing aircraft survivability in hostile environments. However, its limitations include susceptibility to damage from environmental factors and wear, requiring frequent maintenance and reapplication to maintain effectiveness. You should consider that stealth coatings may not fully eliminate radar detection and typically work best when integrated with radar-absorbing structures for comprehensive stealth performance.

Benefits and Challenges of Radar Absorbing Structures

Radar Absorbing Structures (RAS) provide significant benefits such as reducing radar cross-section, enhancing stealth capabilities of military aircraft and naval vessels, and improving survivability in hostile environments. These structures often consist of composite materials designed to absorb and dissipate electromagnetic waves, minimizing detectability. Challenges include the complexity of material engineering, high manufacturing costs, and potential degradation under harsh operational conditions.

Future Trends in Stealth and Radar Evasion Technologies

Future trends in stealth and radar evasion technologies emphasize the integration of advanced stealth coatings with adaptive radar absorbing structures (RAS) to enhance multi-spectrum invisibility. Innovations in metamaterials and nanotechnology enable these materials to dynamically alter their electromagnetic properties, significantly improving radar signature reduction across diverse frequencies. Your ability to incorporate these cutting-edge solutions will define next-generation stealth platforms, offering superior operational advantages in increasingly contested environments.

Stealth Coating vs Radar Absorbing Structure Infographic

libmatt.com

libmatt.com