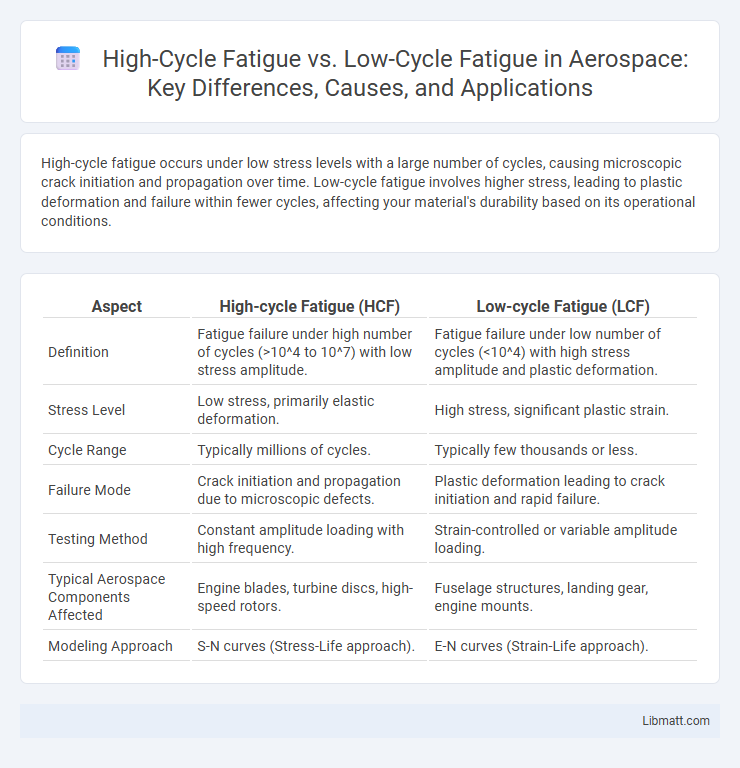

High-cycle fatigue occurs under low stress levels with a large number of cycles, causing microscopic crack initiation and propagation over time. Low-cycle fatigue involves higher stress, leading to plastic deformation and failure within fewer cycles, affecting your material's durability based on its operational conditions.

Table of Comparison

| Aspect | High-cycle Fatigue (HCF) | Low-cycle Fatigue (LCF) |

|---|---|---|

| Definition | Fatigue failure under high number of cycles (>10^4 to 10^7) with low stress amplitude. | Fatigue failure under low number of cycles (<10^4) with high stress amplitude and plastic deformation. |

| Stress Level | Low stress, primarily elastic deformation. | High stress, significant plastic strain. |

| Cycle Range | Typically millions of cycles. | Typically few thousands or less. |

| Failure Mode | Crack initiation and propagation due to microscopic defects. | Plastic deformation leading to crack initiation and rapid failure. |

| Testing Method | Constant amplitude loading with high frequency. | Strain-controlled or variable amplitude loading. |

| Typical Aerospace Components Affected | Engine blades, turbine discs, high-speed rotors. | Fuselage structures, landing gear, engine mounts. |

| Modeling Approach | S-N curves (Stress-Life approach). | E-N curves (Strain-Life approach). |

Introduction to Fatigue in Materials

Fatigue in materials refers to the progressive and localized structural damage that occurs when a material undergoes cyclic loading. High-cycle fatigue (HCF) typically involves a large number of stress cycles, often exceeding 10^4 cycles, where stresses are below the material's yield strength and failure results from crack initiation and propagation over time. Low-cycle fatigue (LCF) occurs under fewer cycles, usually less than 10^4, with higher stress amplitudes causing plastic deformation and rapid accumulation of damage leading to failure.

Defining High-cycle Fatigue (HCF)

High-cycle fatigue (HCF) refers to the failure of materials subjected to a high number of stress cycles, typically exceeding 10^4 to 10^6 cycles, where the stress levels remain below the material's yield strength. This fatigue type predominantly occurs under elastic deformation, involving microscopic crack initiation and propagation over extended periods. In engineering applications, HCF is critical for predicting the lifespan of components like aircraft structures, automotive parts, and rotating machinery operating under repetitive loading conditions.

Understanding Low-cycle Fatigue (LCF)

Low-cycle fatigue (LCF) occurs under high strain levels and results in failure after a relatively low number of cycles, typically less than 10,000 cycles. Unlike high-cycle fatigue, which involves stress levels below the material's yield strength, LCF involves plastic deformation and significant material damage per cycle. Your engineering designs must account for LCF when components are subjected to heavy loads or frequent start-stop operations to ensure durability and safety.

Key Differences: High-cycle vs Low-cycle Fatigue

High-cycle fatigue occurs under high number of stress cycles, typically over 10^4 to 10^6 cycles, with low stress amplitude causing elastic strain, while low-cycle fatigue involves fewer cycles, usually less than 10^4, with higher stress levels leading to plastic deformation. The mechanisms differ as high-cycle fatigue is dominated by crack initiation and propagation under elastic loading, whereas low-cycle fatigue is influenced by cyclic plasticity and strain accumulation. Material fatigue life prediction models like S-N curves apply to high-cycle fatigue, whereas strain-life curves (e-N) are used for low-cycle fatigue analysis.

Stress and Strain Characteristics in HCF and LCF

High-cycle fatigue (HCF) involves low stress levels with elastic strain, resulting in failure after a large number of cycles, typically above 10^4 to 10^5 cycles. Low-cycle fatigue (LCF) undergoes higher stress and plastic strain, causing failure within fewer cycles, generally below 10^4 cycles. Understanding these stress and strain characteristics helps you select materials and design components for appropriate fatigue life in engineering applications.

Fatigue Life Prediction Methods

High-cycle fatigue (HCF) and low-cycle fatigue (LCF) differ primarily in their stress levels and the number of cycles to failure, influencing fatigue life prediction methods. HCF fatigue life prediction often relies on stress-life (S-N) curves derived from cyclic stress amplitude and empirical data, suitable for high-cycle ranges above 10^4 to 10^7 cycles. LCF prediction methods involve strain-life (e-N) approaches incorporating plastic strain effects and Coffin-Manson relations, capturing material behavior under high-stress, low-cycle conditions typically below 10^4 cycles.

Material Behavior Under Cyclic Loading

High-cycle fatigue occurs under low stress levels and typically involves more than 10^4 to 10^6 cycles, where material behavior remains mostly elastic with minor microstructural changes. Low-cycle fatigue happens at higher stress or strain levels, usually below 10^4 cycles, causing significant plastic deformation and accelerated damage accumulation in the material. Understanding these differences helps you predict material life and design components that withstand specific cyclic loading conditions effectively.

Applications and Real-World Examples

High-cycle fatigue (HCF) typically occurs in components subjected to millions of stress cycles at low stress levels, such as aircraft wings and automotive engine parts, where long service life is critical. Low-cycle fatigue (LCF) happens under high stress and fewer cycles, commonly seen in structures like bridges and turbines undergoing frequent start-stop operations or seismic activity. Understanding these fatigue types allows you to select proper materials and design strategies for durability in real-world engineering applications.

Factors Influencing Fatigue Performance

High-cycle fatigue performance is primarily influenced by stress amplitude, surface finish, and environmental conditions such as corrosion and temperature, where microscopic cracks initiate and propagate over millions of cycles under low stress. Low-cycle fatigue is dominated by plastic strain, strain range, and material ductility, with deformation mechanisms and microstructural changes playing crucial roles under high stress and plastic strain for fewer cycles. Both fatigue types are affected by material composition, grain size, and residual stresses, which can enhance or degrade the fatigue life depending on processing and service conditions.

Testing and Standards for HCF and LCF

High-cycle fatigue (HCF) testing typically follows ASTM E466 standards, emphasizing endurance limits under stress amplitudes below the material's yield strength, often employing servo-hydraulic testing machines for millions of stress cycles. Low-cycle fatigue (LCF) testing, guided by standards like ASTM E606, measures plastic strain-controlled fatigue behavior under high strain levels causing failure in a fewer number of cycles, frequently using strain gauges to capture cyclic plastic deformation. Your understanding of these testing methodologies ensures accurate fatigue life prediction by aligning material response with relevant cyclic loading conditions and industry standards.

High-cycle Fatigue vs Low-cycle Fatigue Infographic

libmatt.com

libmatt.com