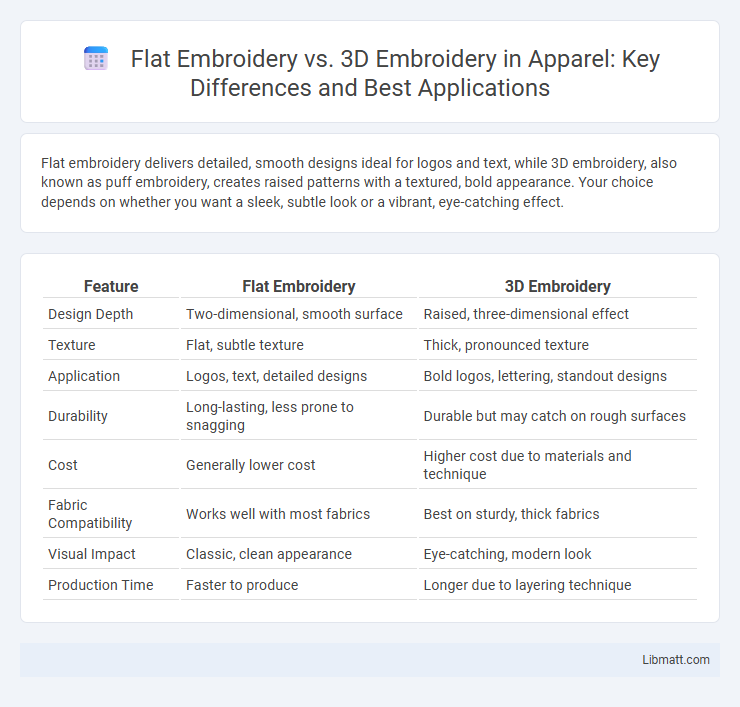

Flat embroidery delivers detailed, smooth designs ideal for logos and text, while 3D embroidery, also known as puff embroidery, creates raised patterns with a textured, bold appearance. Your choice depends on whether you want a sleek, subtle look or a vibrant, eye-catching effect.

Table of Comparison

| Feature | Flat Embroidery | 3D Embroidery |

|---|---|---|

| Design Depth | Two-dimensional, smooth surface | Raised, three-dimensional effect |

| Texture | Flat, subtle texture | Thick, pronounced texture |

| Application | Logos, text, detailed designs | Bold logos, lettering, standout designs |

| Durability | Long-lasting, less prone to snagging | Durable but may catch on rough surfaces |

| Cost | Generally lower cost | Higher cost due to materials and technique |

| Fabric Compatibility | Works well with most fabrics | Best on sturdy, thick fabrics |

| Visual Impact | Classic, clean appearance | Eye-catching, modern look |

| Production Time | Faster to produce | Longer due to layering technique |

Understanding Flat Embroidery

Flat embroidery involves stitching designs directly onto fabric, creating a smooth and detailed texture ideal for logos and intricate patterns. This method uses tightly stitched threads that lay flat against the garment, ensuring durability and visual clarity without adding bulk. Your choice of flat embroidery ensures a classic, professional look that enhances the precision and color vibrancy of your custom designs.

What is 3D Embroidery?

3D embroidery, also known as puff embroidery, creates a raised, three-dimensional effect by using foam under the stitching to add height and texture to your design. Unlike flat embroidery, which lies flush against the fabric, 3D embroidery enhances logos or text with a bold, eye-catching appearance. Your custom apparel benefits from this technique by standing out with a tactile and visually striking finish.

Key Differences Between Flat and 3D Embroidery

Flat embroidery offers a smooth, classic design with threads stitched directly onto the fabric, creating detailed and precise patterns ideal for logos and intricate artwork. In contrast, 3D embroidery, also known as puff embroidery, uses foam under the stitching to elevate and add dimension, giving your designs a bold, raised texture that stands out visually and tactilely. Your choice between flat and 3D embroidery depends on the desired style, fabric type, and the prominence of the embroidered design.

Design Possibilities with Flat Embroidery

Flat embroidery offers extensive design possibilities with its ability to create intricate details and smooth gradients, ideal for logos and text on various fabrics. Its precision enables the reproduction of fine lines and subtle color changes, making it perfect for complex, multi-color designs. Flat embroidery suits lightweight and thinner materials due to its low-profile finish, enhancing comfort and wearability.

Design Capabilities of 3D Embroidery

3D embroidery offers enhanced design capabilities by creating raised, textured patterns that add depth and dimension to any fabric, making logos and motifs more visually striking. Unlike flat embroidery, 3D embroidery uses foam backing to elevate stitches, allowing for intricate designs with a bold, tactile effect that stands out on caps, jackets, and promotional apparel. This technique supports complex layering and shading, delivering a premium, high-impact aesthetic that is highly customizable for branding and fashion statements.

Material Requirements for Each Embroidery Method

Flat embroidery typically requires lightweight stabilizers and standard embroidery threads, making it suitable for thin fabrics like cotton or polyester blends. In contrast, 3D embroidery demands thicker foam backing to create the raised effect, along with high-quality polyester threads that withstand foam compression without losing shape. Proper material selection ensures durability and visual appeal, with 3D embroidery generally necessitating more robust materials to maintain its dimensional structure.

Durability and Maintenance Comparison

Flat embroidery offers moderate durability with its smooth, tightly stitched surface that withstands regular washing and everyday wear, making it low-maintenance for your garments. In contrast, 3D embroidery features raised foam underlay that provides a bold, textured look but may be more prone to wear and deformation over time, requiring gentler care and occasional reshaping. Choosing between the two depends on your preference for longevity versus visual impact and how much maintenance you're willing to invest.

Cost Factors: Flat vs 3D Embroidery

Flat embroidery generally incurs lower costs due to simpler stitch patterns and reduced thread usage, making it ideal for bulk orders and budget-conscious projects. 3D embroidery demands specialized foam backing and additional thread layering, increasing production time and material expenses, which drives up the overall price. Businesses often choose flat embroidery for cost-efficiency, while 3D embroidery is favored for premium, high-impact designs despite the higher investment.

Best Applications for Flat Embroidery

Flat embroidery excels in detailed designs on lightweight fabrics such as cotton and polyester, making it ideal for logos, text, and intricate patterns on shirts, hats, and bags. Its smooth finish is perfect for corporate apparel, uniforms, and promotional products where precision and clarity are essential. Flat embroidery is also cost-effective for large orders and designs requiring multiple colors without added bulk.

When to Choose 3D Embroidery

Choose 3D embroidery when you want to create a bold, raised texture that enhances logos or designs on caps, hats, and apparel for maximum visual impact. This technique works best with thicker threads and foam backing to achieve dimensional effects, making it ideal for promotional products aiming to stand out. Use flat embroidery for intricate designs requiring fine detail, while 3D embroidery excels in highlighting simpler, larger motifs.

flat embroidery vs 3D embroidery Infographic

libmatt.com

libmatt.com