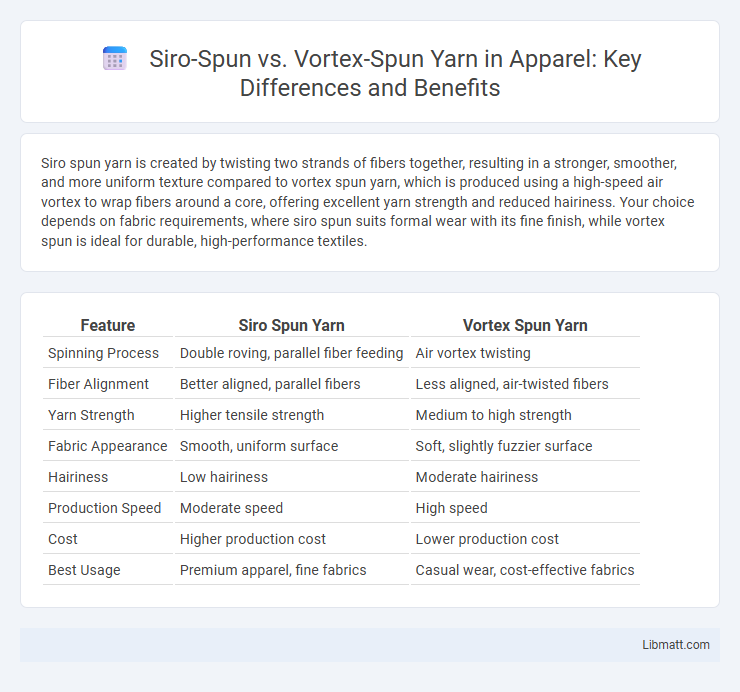

Siro spun yarn is created by twisting two strands of fibers together, resulting in a stronger, smoother, and more uniform texture compared to vortex spun yarn, which is produced using a high-speed air vortex to wrap fibers around a core, offering excellent yarn strength and reduced hairiness. Your choice depends on fabric requirements, where siro spun suits formal wear with its fine finish, while vortex spun is ideal for durable, high-performance textiles.

Table of Comparison

| Feature | Siro Spun Yarn | Vortex Spun Yarn |

|---|---|---|

| Spinning Process | Double roving, parallel fiber feeding | Air vortex twisting |

| Fiber Alignment | Better aligned, parallel fibers | Less aligned, air-twisted fibers |

| Yarn Strength | Higher tensile strength | Medium to high strength |

| Fabric Appearance | Smooth, uniform surface | Soft, slightly fuzzier surface |

| Hairiness | Low hairiness | Moderate hairiness |

| Production Speed | Moderate speed | High speed |

| Cost | Higher production cost | Lower production cost |

| Best Usage | Premium apparel, fine fabrics | Casual wear, cost-effective fabrics |

Introduction to Yarn Spinning Technologies

Siro spun yarn utilizes a twin-roller spinning process that twists two rovings simultaneously, producing stronger and smoother yarn with reduced hairiness compared to vortex spun yarn. Vortex spun yarn is created using high-velocity air currents to wrap fibers around a core, resulting in bulky, bulky soft yarn with excellent abrasion resistance and low hairiness. Both technologies offer distinct advantages for textile manufacturers seeking enhanced yarn quality and performance in various fabric applications.

What is Siro Spun Yarn?

Siro spun yarn is a type of cotton yarn produced by simultaneously feeding two rovings into the spinning frame, resulting in a stronger and smoother yarn with reduced hairiness compared to conventional ring-spun yarns. This process combines the advantages of rotor spun and ring spun yarn, offering enhanced fabric strength, softness, and better pilling resistance, making it ideal for high-quality apparel and textiles. Your choice of Siro spun yarn ensures improved fabric durability and a refined hand feel compared to vortex spun yarn, which uses a different spinning mechanism focused on air vortex to twist fibers.

What is Vortex Spun Yarn?

Vortex spun yarn is produced using an air-jet spinning technology that twists fibers by high-velocity air streams, resulting in strong, uniform yarn with low hairiness and enhanced durability. This method combines the advantages of ring and open-end spinning, delivering smooth yarn ideal for high-quality textiles and reducing production time. Vortex spinning creates yarn with superior abrasion resistance and consistent strength, making it preferred for applications requiring both comfort and durability.

Key Differences Between Siro Spun and Vortex Spun

Siro spun yarn is created by simultaneously twisting two rovings, resulting in a smoother, stronger, and more uniform fabric with reduced hairiness, ideal for fine cotton products. Vortex spun yarn uses high-speed air to twist fibers, producing yarns with excellent strength, high evenness, and minimal pilling, suitable for uniform and durable textiles. The key differences lie in the twisting technique, with Siro spun emphasizing fiber alignment for softness and Vortex spun focusing on aerodynamic twisting for robustness and durability.

Production Process: Siro vs. Vortex Spinning

Siro spun yarn is produced by simultaneously feeding two rovings into the drafting system, twisting them together to create a strong, uniform yarn with minimal hairiness. Vortex spinning, on the other hand, uses high-speed air jets to twist and wrap fibers around a core, resulting in a smoother, more compact yarn ideal for high-quality fabrics. Both methods enhance yarn strength and appearance but differ significantly in fiber separation and twisting techniques.

Fiber Compatibility and Raw Materials

Siro spun yarn offers enhanced fiber compatibility, allowing a broader range of raw materials such as cotton, wool, and polyester blends to be efficiently processed with minimal fiber breakage. Vortex spun yarn, on the other hand, is optimized for synthetic fibers and blends but may struggle with natural fibers due to the high-speed air vortex spinning process. Your choice between Siro spun and vortex spun yarn should consider the raw material type to ensure optimal strength, uniformity, and fabric performance.

Yarn Properties: Strength, Evenness, and Hairiness

Siro spun yarn exhibits higher strength and better evenness compared to vortex spun yarn due to its unique twin-fiber drafting system, which aligns fibers more parallelly and reduces hairiness. Vortex spun yarn is characterized by lower hairiness and improved abrasion resistance because of its air vortex spinning method, resulting in a smoother surface and higher durability. The choice between Siro spun and vortex spun yarns depends on the required balance of yarn strength, evenness, and hairiness for specific textile applications.

Applications of Siro Spun Yarn

Siro spun yarn is widely used in high-quality textiles such as shirting, dresses, and bed linens due to its enhanced strength and smoothness compared to conventional ring-spun yarns. Its even fiber distribution minimizes pilling and enhances fabric durability, making it ideal for garments requiring a soft hand feel and long-term wear. The fine and uniform structure of Siro yarn is particularly favored in applications demanding lightweight, breathable fabrics with superior appearance and performance.

Applications of Vortex Spun Yarn

Vortex spun yarn is widely used in denim, shirting, and home textiles due to its smooth surface, high strength, and excellent pilling resistance. Its superior uniformity and durability make it ideal for activewear and industrial fabrics that demand robust performance. The yarn's cost-effectiveness and high productivity drive its adoption in large-scale textile manufacturing.

Choosing Between Siro Spun and Vortex Spun Yarns

Choosing between Siro spun and vortex spun yarns depends on the desired fabric characteristics and end-use applications. Siro spun yarns offer superior softness and strength due to their unique double drafting process, making them ideal for high-quality textiles and apparel, while vortex spun yarns provide excellent uniformity, abrasion resistance, and reduced hairiness, suitable for performance fabrics and industrial uses. Your choice should align with specific product requirements, balancing comfort, durability, and production efficiency.

Siro spun vs vortex spun Infographic

libmatt.com

libmatt.com