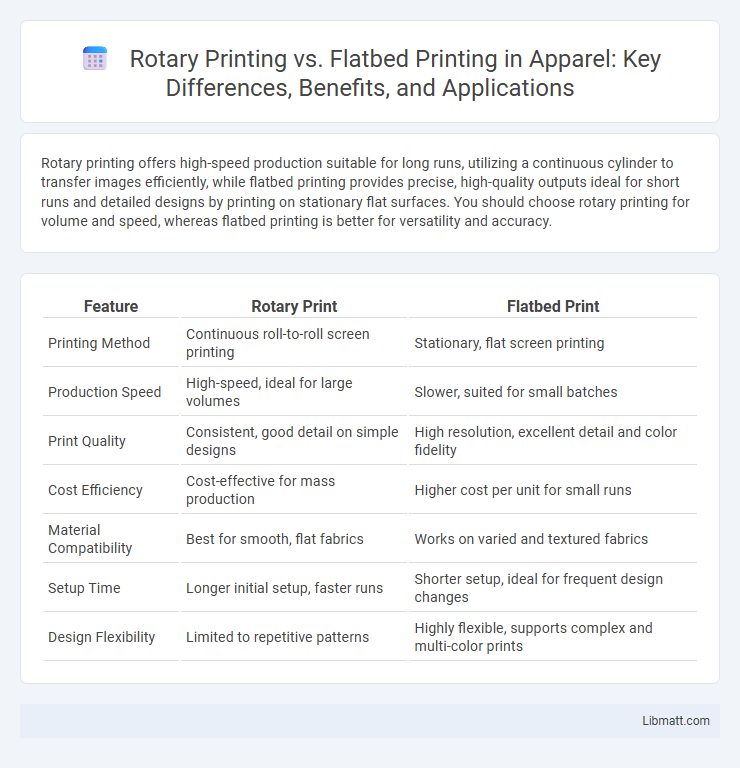

Rotary printing offers high-speed production suitable for long runs, utilizing a continuous cylinder to transfer images efficiently, while flatbed printing provides precise, high-quality outputs ideal for short runs and detailed designs by printing on stationary flat surfaces. You should choose rotary printing for volume and speed, whereas flatbed printing is better for versatility and accuracy.

Table of Comparison

| Feature | Rotary Print | Flatbed Print |

|---|---|---|

| Printing Method | Continuous roll-to-roll screen printing | Stationary, flat screen printing |

| Production Speed | High-speed, ideal for large volumes | Slower, suited for small batches |

| Print Quality | Consistent, good detail on simple designs | High resolution, excellent detail and color fidelity |

| Cost Efficiency | Cost-effective for mass production | Higher cost per unit for small runs |

| Material Compatibility | Best for smooth, flat fabrics | Works on varied and textured fabrics |

| Setup Time | Longer initial setup, faster runs | Shorter setup, ideal for frequent design changes |

| Design Flexibility | Limited to repetitive patterns | Highly flexible, supports complex and multi-color prints |

Introduction to Rotary Print and Flatbed Print

Rotary print utilizes a continuous cylindrical screen that rotates to transfer ink onto fabric or paper, allowing high-speed production with consistent image quality. Flatbed print involves a stationary screen where the substrate moves underneath or the print head moves over a flat surface, ideal for detailed designs and variable print sizes. Both technologies serve distinct industrial applications, with rotary print excelling in large volume runs while flatbed print offers greater precision for specialty prints.

How Rotary Printing Works

Rotary printing works by continuously feeding a substrate through rotating cylinders, where the image is transferred from engraved plates to the material in a high-speed process suitable for long runs. This method allows consistent ink application and fast production, making it ideal for printing on flexible materials like fabric, paper, or plastic films. Your choice of rotary printing ensures efficient, seamless output for large-volume printing jobs compared to flatbed printing's slower, stationary method.

How Flatbed Printing Works

Flatbed printing operates by securing a rigid substrate on a flat surface while a print head moves in a precise pattern to deposit ink directly onto the material. This method enables high-resolution prints on diverse surfaces like wood, metal, glass, and acrylic, offering superior detail and color accuracy compared to rotary printing. The stationary nature of the substrate during flatbed printing reduces distortion and enables precise control over ink application, making it ideal for short runs and complex designs.

Key Differences Between Rotary and Flatbed Printing

Rotary print uses cylindrical screens to continuously transfer images onto curved or flexible surfaces, offering high-speed production ideal for textiles and packaging. Flatbed print employs a flat platen where substrates remain stationary during ink application, providing exceptional detail and precision for rigid materials like glass, wood, or metal. Key differences include production speed, substrate compatibility, and image resolution, with rotary printing excelling in volume and flatbed printing prioritizing versatility and accuracy.

Print Speed and Efficiency Comparison

Rotary printing presses achieve higher print speeds by continuously feeding materials through a cylindrical drum, enabling fast, large-volume production with consistent output. Flatbed printing operates at slower speeds due to its static, step-and-repeat process, which limits throughput but allows for high precision on rigid or irregular surfaces. For industries prioritizing rapid turnaround and bulk printing, rotary printing offers superior efficiency, whereas flatbed printing is preferred when detailed customization outweighs speed.

Quality and Detail: Rotary vs Flatbed Print

Rotary printing offers high-speed production suitable for large runs but may compromise fine detail and subtle color variations compared to flatbed printing, which excels in producing sharp, precise images with intricate detail on various materials. Flatbed printers use advanced UV or solvent inks to achieve superior color fidelity and crispness, making them ideal for projects where quality and intricate design matter most. Your choice depends on whether you prioritize quantity and speed (rotary) or exceptional detail and quality (flatbed).

Cost Analysis: Rotary Print vs Flatbed Print

Rotary print typically offers lower cost per unit for high-volume runs due to faster production speeds and efficient continuous printing, making it ideal for large-scale projects. Flatbed print incurs higher initial setup and maintenance costs but provides superior quality and flexibility for short runs, specialty materials, or complex designs. Your choice depends on balancing quantity, budget constraints, and desired print quality to maximize cost efficiency.

Material Compatibility and Versatility

Rotary print excels in handling flexible, continuous materials like fabrics, plastics, and thin films, enabling high-speed production with consistent quality. Flatbed print offers superior versatility for rigid or thick substrates such as wood, glass, metal, and acrylic, supporting diverse shapes and sizes with precise image placement. Your choice depends on the material type and project requirements, with rotary suited for large runs on pliable materials and flatbed ideal for heavyweight, non-flexible items.

Ideal Applications for Rotary and Flatbed Printing

Rotary printing excels in high-volume production runs such as packaging labels, newspapers, and textiles due to its continuous roll-to-roll process that ensures speed and efficiency. Flatbed printing is ideal for detailed, small-batch jobs involving rigid substrates like wood, glass, and metal, offering precise image quality and versatility for custom designs. Your choice depends on whether you prioritize fast, large-scale output or intricate, durable prints on diverse materials.

Choosing the Right Printing Method for Your Needs

Rotary print excels in high-speed production and continuous patterns, making it ideal for large-volume projects requiring consistent, seamless designs on flexible materials. Flatbed print offers superior precision and versatility for detailed, multi-layered images on rigid or irregular surfaces, suited for smaller runs or customized prints. Evaluating factors such as project scale, substrate type, and design complexity helps determine whether rotary or flatbed printing best meets your specific requirements.

Rotary print vs flatbed print Infographic

libmatt.com

libmatt.com