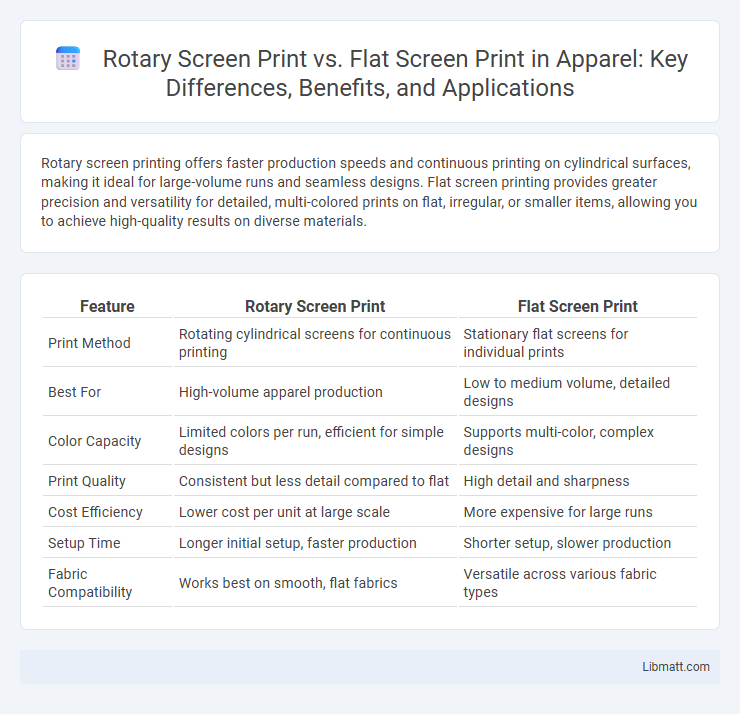

Rotary screen printing offers faster production speeds and continuous printing on cylindrical surfaces, making it ideal for large-volume runs and seamless designs. Flat screen printing provides greater precision and versatility for detailed, multi-colored prints on flat, irregular, or smaller items, allowing you to achieve high-quality results on diverse materials.

Table of Comparison

| Feature | Rotary Screen Print | Flat Screen Print |

|---|---|---|

| Print Method | Rotating cylindrical screens for continuous printing | Stationary flat screens for individual prints |

| Best For | High-volume apparel production | Low to medium volume, detailed designs |

| Color Capacity | Limited colors per run, efficient for simple designs | Supports multi-color, complex designs |

| Print Quality | Consistent but less detail compared to flat | High detail and sharpness |

| Cost Efficiency | Lower cost per unit at large scale | More expensive for large runs |

| Setup Time | Longer initial setup, faster production | Shorter setup, slower production |

| Fabric Compatibility | Works best on smooth, flat fabrics | Versatile across various fabric types |

Introduction to Rotary and Flat Screen Printing

Rotary screen printing utilizes a cylindrical mesh screen that continuously rotates, allowing for high-speed, efficient printing on fabrics and other materials. Flat screen printing employs a flat mesh screen where ink is applied manually or mechanically through a stencil, ideal for detailed designs and lower production volumes. Both techniques serve distinct industrial needs, with rotary screens excelling in rapid, large-scale output and flat screens offering precision and versatility.

How Rotary Screen Printing Works

Rotary screen printing works by using a cylindrical mesh screen that rotates continuously as your substrate moves through the press, allowing for high-speed and efficient printing on fabrics or other materials. Ink is forced through the rotating screen onto the material, enabling consistent, vibrant patterns with fine detail over large production runs. This method is ideal for printing long, continuous designs with precise color registration and minimal downtime.

How Flat Screen Printing Works

Flat screen printing involves using a stencil or mesh screen with open areas that allow ink to pass through onto the printing surface, creating the desired image. In this process, the screen is held stationary while a squeegee pushes ink across the screen, forcing ink through the mesh openings in specific shapes. Your designs benefit from precise ink application and vibrant colors, making flat screen printing ideal for detailed images on flat materials.

Key Differences Between Rotary and Flat Screen Printing

Rotary screen printing uses a cylindrical mesh screen that rotates continuously, enabling high-speed production ideal for large-volume textile printing. Flat screen printing employs a stationary flat mesh screen, suitable for detailed designs and smaller print runs due to slower processing speeds. The key differences lie in speed, production volume, and design complexity, with rotary excelling in efficiency and flat screen offering greater precision.

Print Quality: Rotary vs Flat Screen Printing

Rotary screen printing offers faster production speeds with consistent quality, making it ideal for long runs and patterns requiring seamless repetition. Flat screen printing provides higher precision and detail, producing sharper images and better color vibrancy, especially suitable for intricate designs and short runs. The choice between rotary and flat screen printing depends on balancing speed and print quality based on project requirements.

Speed and Efficiency Comparison

Rotary screen printing offers significantly higher speed and efficiency, producing continuous patterns at rates exceeding 150 meters per minute, ideal for large-volume textile production. In contrast, flat screen printing operates at slower speeds, around 20-30 meters per minute, due to its step-by-step process and manual screen changes, making it better suited for shorter runs and intricate designs. The continuous motion of rotary screens minimizes downtime and labor, enhancing overall production efficiency compared to the intermittent process of flat screen printing.

Cost Analysis: Rotary vs Flat Screen

Rotary screen printing typically incurs higher initial setup costs due to specialized cylindrical screens but offers lower per-unit costs in large production runs, making it cost-effective for high-volume printing. Flat screen printing has lower setup expenses and is suitable for small to medium batches, resulting in higher per-unit costs as volume increases. Choosing between rotary and flat screen printing depends on the production scale, with rotary preferred for mass production and flat screen optimal for smaller quantities to minimize overall costs.

Design Flexibility and Limitations

Rotary screen printing offers high-speed production and is ideal for continuous patterns but limits design flexibility to simpler, repetitive motifs due to its cylindrical screen structure. Flat screen printing enables greater design complexity with precise, multi-layered images and diverse color options, accommodating intricate details and variations. Your choice depends on whether you prioritize efficiency and volume or detailed customization in your print designs.

Applications and Best Uses for Each Method

Rotary screen printing excels in high-volume textile production, making it ideal for continuous patterns on fabrics like t-shirts, upholstery, and home textiles due to its speed and efficiency. Flat screen printing is better suited for small to medium runs with complex or multi-colored designs, often used in promotional products, custom apparel, and detailed graphic prints where precision and versatility are critical. Selecting between these methods depends on production scale, design complexity, and fabric type to achieve optimal quality and cost-effectiveness.

Choosing the Right Screen Printing Technique

Rotary screen printing excels in high-volume production with continuous patterns, offering faster throughput and efficient ink usage, making it ideal for fabrics and long runs. Flat screen printing provides superior precision and versatility on various substrates, perfect for detailed designs and smaller batches requiring sharp image quality. Selecting between rotary and flat screen printing depends on project scale, design intricacy, and fabric type to ensure optimal results and cost-effectiveness.

Rotary Screen Print vs Flat Screen Print Infographic

libmatt.com

libmatt.com