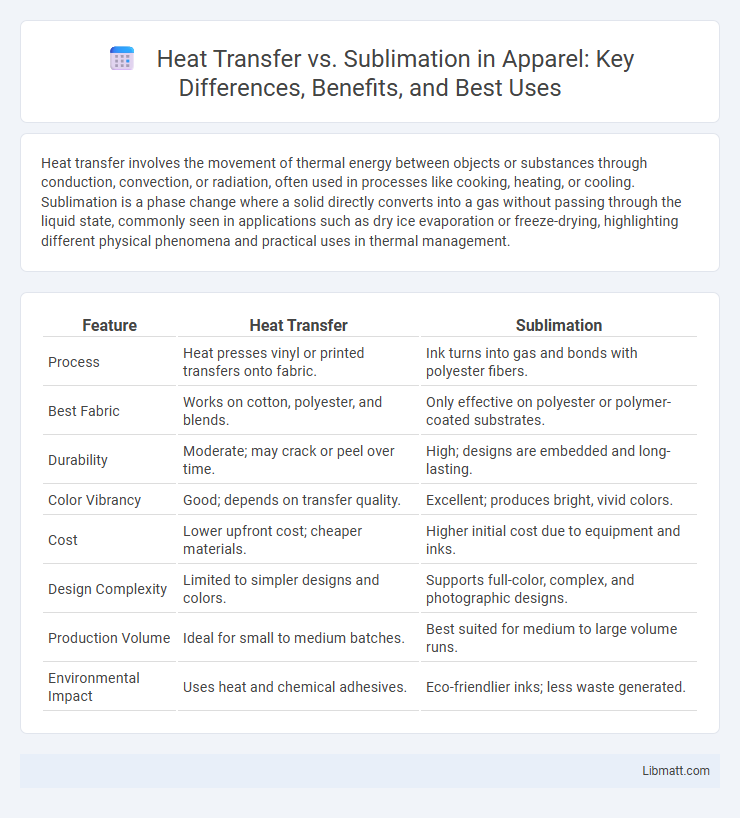

Heat transfer involves the movement of thermal energy between objects or substances through conduction, convection, or radiation, often used in processes like cooking, heating, or cooling. Sublimation is a phase change where a solid directly converts into a gas without passing through the liquid state, commonly seen in applications such as dry ice evaporation or freeze-drying, highlighting different physical phenomena and practical uses in thermal management.

Table of Comparison

| Feature | Heat Transfer | Sublimation |

|---|---|---|

| Process | Heat presses vinyl or printed transfers onto fabric. | Ink turns into gas and bonds with polyester fibers. |

| Best Fabric | Works on cotton, polyester, and blends. | Only effective on polyester or polymer-coated substrates. |

| Durability | Moderate; may crack or peel over time. | High; designs are embedded and long-lasting. |

| Color Vibrancy | Good; depends on transfer quality. | Excellent; produces bright, vivid colors. |

| Cost | Lower upfront cost; cheaper materials. | Higher initial cost due to equipment and inks. |

| Design Complexity | Limited to simpler designs and colors. | Supports full-color, complex, and photographic designs. |

| Production Volume | Ideal for small to medium batches. | Best suited for medium to large volume runs. |

| Environmental Impact | Uses heat and chemical adhesives. | Eco-friendlier inks; less waste generated. |

Introduction to Heat Transfer and Sublimation

Heat transfer and sublimation are distinct methods used for applying designs onto fabrics, each with unique processes and results. Heat transfer involves using heat and pressure to transfer a design from a carrier film to your garment, providing vibrant and durable prints. Sublimation uses heat to convert dye into gas, embedding the design directly into polyester fibers for a smooth, long-lasting finish without altering fabric texture.

What is Heat Transfer?

Heat transfer is a printing technique that uses heat and pressure to transfer dye or vinyl from a carrier film onto a substrate, such as fabric or paper. This method allows for vibrant, durable designs with excellent color accuracy and is widely used in garment decoration and promotional products. The process involves a heat press machine that activates the adhesive on the transfer material, bonding it securely to the target surface.

What is Sublimation Printing?

Sublimation printing is a process where heat transfers dye directly onto materials like fabric or plastic, turning the dye into gas without passing through a liquid state. This technique allows for vibrant, durable images that become part of the material itself, ideal for personalized apparel and promotional products. Your designs benefit from high-resolution, long-lasting colors that don't peel or fade over time.

Key Differences Between Heat Transfer and Sublimation

Heat transfer uses heat and pressure to apply vinyl or other materials onto a surface, resulting in a textured, layered finish, while sublimation involves converting solid dye into gas to permanently bond with polyester fabrics, producing vibrant, embedded designs. Heat transfer works well on various materials like cotton, polyester, and blends, but sublimation is limited to light-colored, polyester-based fabrics for optimal color vibrancy and durability. Understanding these key differences ensures your project matches the method that best suits the fabric type and desired visual effect.

Materials Compatible with Heat Transfer

Heat transfer is compatible with a wide range of materials including cotton, polyester, nylon, and blends, making it ideal for customizing garments, accessories, and home textiles. Unlike sublimation, which works best on polyester or polymer-coated surfaces, heat transfer vinyl (HTV) adheres well to natural fibers and synthetic fabrics, providing vibrant, durable designs. This versatility allows heat transfer to be used on diverse products such as t-shirts, tote bags, and caps without compromising color quality or material integrity.

Materials Compatible with Sublimation

Sublimation works best on materials coated with polyester or those made entirely of polyester, enabling vibrant, long-lasting prints due to the dye's ability to bond with polyester fibers at the molecular level. Materials such as ceramics, metals, and specially coated plastics can also be compatible with sublimation, making it ideal for customizing mugs, phone cases, and promotional products. You should avoid cotton or natural fabrics for sublimation, as they lack the necessary synthetic fibers to hold the dye effectively.

Durability and Quality Comparison

Heat transfer offers superior durability, with vibrant designs resistant to cracking and fading after multiple washes. Sublimation, while producing high-quality, detailed prints with excellent color vibrancy, is limited to polyester fabrics and may lose intensity on lower-quality materials. Both methods maintain good overall quality, but heat transfer provides enhanced longevity on diverse fabric types.

Cost and Equipment Considerations

Heat transfer typically requires lower initial investment with affordable equipment like heat presses, making it suitable for small businesses and startups. Sublimation demands specialized printers and high-quality sublimation inks, resulting in higher upfront costs but offers superior color vibrancy and durability for polyester or coated substrates. Evaluating production volume and substrate compatibility is crucial when balancing the cost-efficiency and equipment requirements of each method.

Common Applications of Each Method

Heat transfer is commonly used for applying designs onto fabrics, promotional products, and sportswear due to its cost-efficiency and durability. Sublimation excels in producing vibrant, high-resolution prints on polyester garments, ceramic mugs, and metal photo panels, offering exceptional color depth and fade resistance. Both methods serve unique niches in custom printing, with heat transfer favored for versatility and sublimation for color brilliance.

Which Printing Method is Right for You?

Heat transfer printing offers vibrant colors and works well on a variety of fabrics, making it ideal for custom designs with moderate durability, while sublimation provides long-lasting, high-resolution prints perfect for polyester materials and all-over designs. Your choice depends on the fabric type, design complexity, and intended use; heat transfer suits cotton and blends, whereas sublimation excels on polyester and synthetic fabrics. Consider the desired print durability and color vibrancy to determine which printing method aligns with your project needs.

Heat Transfer vs Sublimation Infographic

libmatt.com

libmatt.com