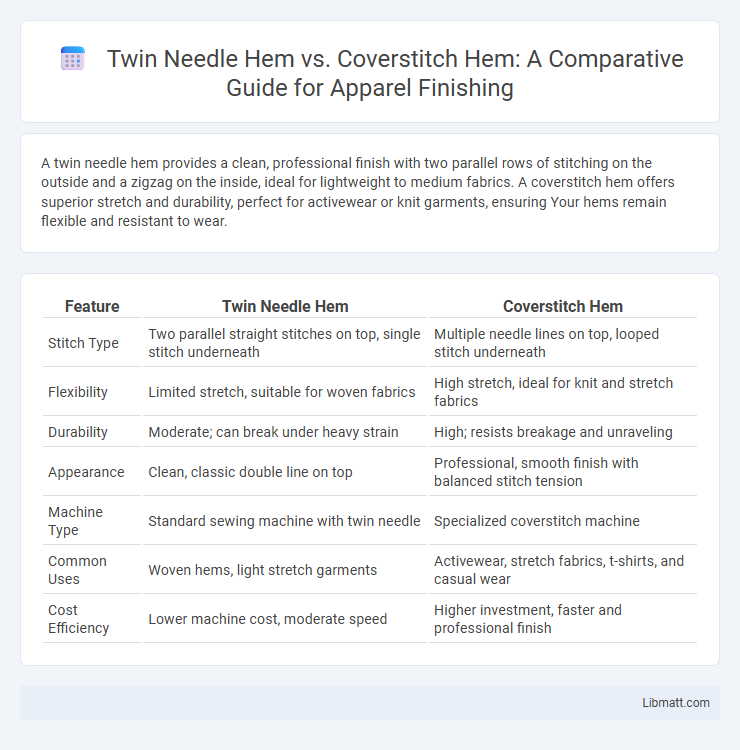

A twin needle hem provides a clean, professional finish with two parallel rows of stitching on the outside and a zigzag on the inside, ideal for lightweight to medium fabrics. A coverstitch hem offers superior stretch and durability, perfect for activewear or knit garments, ensuring Your hems remain flexible and resistant to wear.

Table of Comparison

| Feature | Twin Needle Hem | Coverstitch Hem |

|---|---|---|

| Stitch Type | Two parallel straight stitches on top, single stitch underneath | Multiple needle lines on top, looped stitch underneath |

| Flexibility | Limited stretch, suitable for woven fabrics | High stretch, ideal for knit and stretch fabrics |

| Durability | Moderate; can break under heavy strain | High; resists breakage and unraveling |

| Appearance | Clean, classic double line on top | Professional, smooth finish with balanced stitch tension |

| Machine Type | Standard sewing machine with twin needle | Specialized coverstitch machine |

| Common Uses | Woven hems, light stretch garments | Activewear, stretch fabrics, t-shirts, and casual wear |

| Cost Efficiency | Lower machine cost, moderate speed | Higher investment, faster and professional finish |

Introduction to Hemming Techniques

Twin needle hem and coverstitch hem represent two essential hemming techniques widely used in garment construction to achieve durable, stretchable finishes. Twin needle hemming utilizes two parallel needles to create a double row of stitching on the right side and a zigzag pattern on the underside, ideal for lightweight to medium fabrics. Coverstitch hemming employs a specialized machine producing a professional-quality, flat stretch seam with multiple thread loops on the underside, perfect for activewear and knit fabrics.

What is a Twin Needle Hem?

A twin needle hem uses two parallel needles to create two rows of stitching on the front and a zigzag pattern on the back, offering flexibility and durability ideal for knit fabrics. This technique mimics a professional finish similar to coverstitching but can be done on a standard sewing machine without specialized equipment. It provides stretchability and prevents seams from breaking, making it popular for hemming t-shirts, activewear, and stretchy garments.

What is a Coverstitch Hem?

A coverstitch hem is a professional sewing finish commonly used on knit fabrics, creating a durable, stretchable seam with parallel rows of stitching on the outside and a serged-like cover on the underside. Unlike a twin needle hem, which uses two parallel needles for stitching, the coverstitch machine simultaneously sews the hem and covers the raw edge, preventing fraying and adding flexibility. Your garments achieve a polished, commercial-quality look with improved seam strength and elasticity, ideal for activewear and casual clothing.

Visual Differences: Twin Needle vs Coverstitch

Twin needle hems feature two parallel lines of stitching on the top side with a zigzag or straight stitch underneath, creating a clean and professional look ideal for lightweight to medium fabrics. Coverstitch hems show two or more rows of straight stitches on the top and a wide, multi-thread looped pattern on the underside, providing excellent stretch and durability for knit garments. The visual distinction lies in the underside stitch pattern--zigzag for twin needle and looped threads for coverstitch--making each easily identifiable by fabric crafters and apparel manufacturers.

Fabric Compatibility for Each Hem

Twin needle hems are ideal for lightweight to medium-weight fabrics such as cotton, linen, and knits, providing a clean, stretchy finish without bulk. Coverstitch hems excel on medium to heavyweight knit fabrics like jerseys, interlock, and fleece, offering superior stretch recovery and deep seams. Choosing the appropriate hem depends on fabric thickness and elasticity to ensure durability and flexibility in garment construction.

Durability and Stretch: Which Hem Wins?

Twin needle hems offer moderate durability and stretch, making them suitable for lightweight fabrics but prone to thread breakage under heavy strain. Coverstitch hems provide superior durability and flexibility, ideal for activewear and stretchy fabrics due to their reinforced stitching and ability to maintain elasticity. Your choice depends on fabric type and usage, but coverstitch hems generally win for lasting stretch and strength.

Required Tools and Equipment

Twin needle hems require a sewing machine equipped with a twin needle attachment and standard sewing threads, making it suitable for lightweight to medium-weight fabrics. Coverstitch hems demand a specialized coverstitch machine or a serger with coverstitch capability, along with dual or triple thread cones to create professional, stretchable finishes ideal for knitwear and activewear. Your choice depends on the tools you have access to and the fabric type you intend to work with.

Step-by-Step Process: Twin Needle Hem

The twin needle hem process begins by setting up your sewing machine with a twin needle and matching thread in both needles and the bobbin to ensure parallel rows of stitching. Align the fabric edge, fold it under to the desired hem width, then sew slowly to maintain even tension and prevent fabric puckering. Your twin needle hem features two straight stitches on top and a zigzag stitch underneath, providing a stretchable, professional finish ideal for knit garments.

Step-by-Step Process: Coverstitch Hem

The coverstitch hem process begins by folding the fabric edge up, then placing it under the presser foot of a coverstitch machine equipped with two or three needles. Stitching is performed with simultaneous top and bottom thread loops, creating a durable, elastic hem ideal for knit fabrics. This method ensures a professional, stretchable finish, with the bottom loops securing the fabric and the top parallel stitches providing a clean appearance.

Choosing the Best Hem for Your Project

Choosing the best hem for your project depends on fabric type and desired stretch; twin needle hems are ideal for lightweight to medium knits, providing a classic, clean finish suitable for less stretchy fabrics. Coverstitch hems offer superior durability and flexibility, making them perfect for activewear or heavy knits requiring robust seams that stretch without breaking. Evaluate your fabric's stretch and the hem's intended use to make the optimal choice that ensures Your garment's functionality and professional appearance.

Twin Needle Hem vs Coverstitch Hem Infographic

libmatt.com

libmatt.com