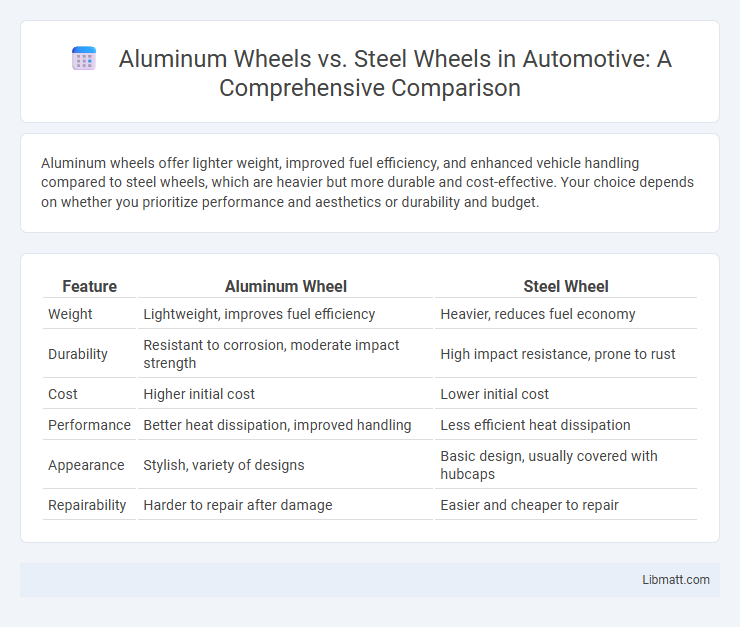

Aluminum wheels offer lighter weight, improved fuel efficiency, and enhanced vehicle handling compared to steel wheels, which are heavier but more durable and cost-effective. Your choice depends on whether you prioritize performance and aesthetics or durability and budget.

Table of Comparison

| Feature | Aluminum Wheel | Steel Wheel |

|---|---|---|

| Weight | Lightweight, improves fuel efficiency | Heavier, reduces fuel economy |

| Durability | Resistant to corrosion, moderate impact strength | High impact resistance, prone to rust |

| Cost | Higher initial cost | Lower initial cost |

| Performance | Better heat dissipation, improved handling | Less efficient heat dissipation |

| Appearance | Stylish, variety of designs | Basic design, usually covered with hubcaps |

| Repairability | Harder to repair after damage | Easier and cheaper to repair |

Introduction: Aluminum Wheels vs Steel Wheels

Aluminum wheels offer better heat dissipation and lightweight advantages compared to steel wheels, improving fuel efficiency and handling performance. Steel wheels provide superior durability and resistance to impact damage, making them ideal for rough terrains and heavy-duty use. The choice between aluminum and steel wheels depends on factors like vehicle type, driving conditions, and budget considerations.

Material Composition and Manufacturing Process

Aluminum wheels are primarily made from lightweight aluminum alloys that provide superior corrosion resistance and enable intricate designs through casting or forging processes, enhancing both performance and aesthetics. Steel wheels consist of heavier, more durable steel stamped and welded into shape, offering cost-effective strength but less flexibility in design and a higher susceptibility to rust without protective coatings. Your choice depends on whether you prioritize lightweight performance and style from aluminum or rugged durability and affordability from steel.

Weight and Performance Comparison

Aluminum wheels typically weigh 30-50% less than steel wheels, significantly reducing unsprung mass and improving vehicle handling and acceleration. The lighter weight of aluminum enhances fuel efficiency and offers better performance in braking due to lower rotational inertia. Your choice between aluminum and steel wheels can directly impact agility, ride quality, and overall driving dynamics.

Durability and Strength Differences

Aluminum wheels offer lighter weight and enhanced corrosion resistance compared to steel wheels, but steel wheels typically provide greater impact strength and resistance to bending under heavy loads. The durability of steel wheels makes them ideal for rugged terrains and harsh driving conditions, while aluminum wheels, despite being more prone to cracking under extreme stress, maintain structural integrity through advanced alloy compositions. Steel's denser metal structure grants superior toughness, whereas aluminum alloys optimize the balance between strength and weight for improved vehicle performance.

Cost Analysis: Initial Purchase and Long-Term Value

Aluminum wheels generally have a higher initial purchase cost compared to steel wheels due to their lighter weight and superior aesthetics. However, aluminum wheels offer long-term value through improved fuel efficiency and reduced wear on suspension components, which can lower maintenance expenses over time. Steel wheels, while more budget-friendly upfront, tend to incur higher costs in the long run due to increased weight affecting fuel consumption and a greater likelihood of rust and damage.

Aesthetic Appeal and Customization Options

Aluminum wheels offer superior aesthetic appeal with sleek finishes and intricate designs that enhance vehicle appearance, favored by enthusiasts for their modern and stylish look. Steel wheels provide a more utilitarian design, often coated in black or silver, with limited customization options but valued for durability and affordability. Customization possibilities in aluminum wheels include various sizes, colors, and finishes, while steel wheels typically remain basic to maintain cost-effectiveness and ruggedness.

Fuel Efficiency Impact of Wheel Material

Aluminum wheels are lighter than steel wheels, reducing the overall weight of your vehicle and improving fuel efficiency by decreasing rolling resistance. The lower weight enhances acceleration and braking performance, leading to less energy consumption during driving. Choosing aluminum wheels supports better mileage and can contribute to long-term fuel savings.

Maintenance Requirements and Longevity

Aluminum wheels require less maintenance than steel wheels due to their resistance to rust and corrosion, making them ideal for environments with frequent exposure to moisture. Steel wheels, while typically more durable in impact situations, demand regular inspection and treatment to prevent rust and prolong their lifespan. If you seek low-maintenance performance with a longer-lasting finish, aluminum wheels offer a significant advantage.

Suitability for Various Driving Conditions

Aluminum wheels offer superior performance in dry and mild conditions due to their lightweight structure, which enhances handling and fuel efficiency. Steel wheels, known for their durability and toughness, excel in harsh driving environments like snowy or off-road conditions where impact resistance is crucial. Choosing between the two depends on specific driving needs, with aluminum favored for everyday urban use and steel preferred for rugged, demanding terrains.

Conclusion: Choosing Between Aluminum and Steel Wheels

Aluminum wheels offer superior performance benefits such as reduced weight, improved fuel efficiency, and enhanced aesthetics, making them ideal for drivers seeking style and handling. Steel wheels provide greater durability and affordability, often preferred for harsh driving conditions or budget-conscious vehicle owners. Choosing between aluminum and steel wheels depends on priorities like cost, performance, and driving environment.

Aluminum wheel vs Steel wheel Infographic

libmatt.com

libmatt.com