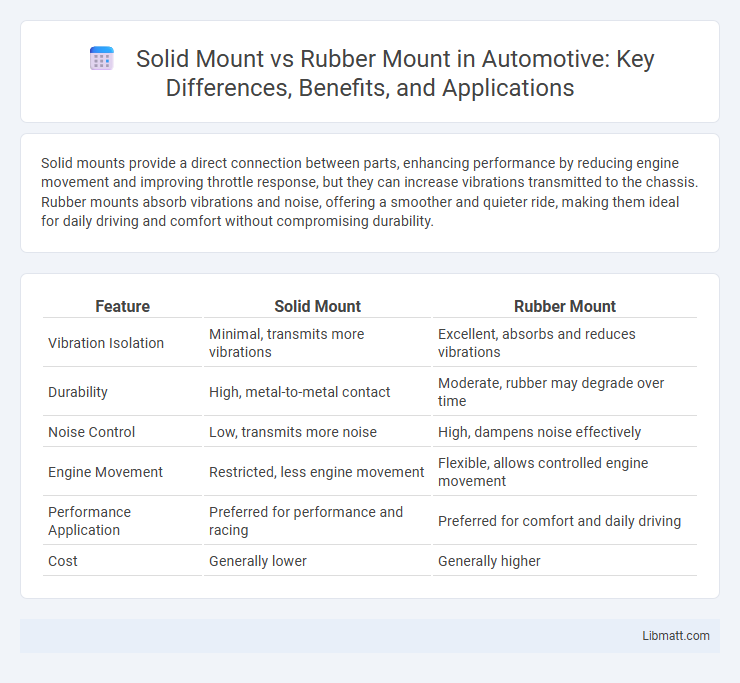

Solid mounts provide a direct connection between parts, enhancing performance by reducing engine movement and improving throttle response, but they can increase vibrations transmitted to the chassis. Rubber mounts absorb vibrations and noise, offering a smoother and quieter ride, making them ideal for daily driving and comfort without compromising durability.

Table of Comparison

| Feature | Solid Mount | Rubber Mount |

|---|---|---|

| Vibration Isolation | Minimal, transmits more vibrations | Excellent, absorbs and reduces vibrations |

| Durability | High, metal-to-metal contact | Moderate, rubber may degrade over time |

| Noise Control | Low, transmits more noise | High, dampens noise effectively |

| Engine Movement | Restricted, less engine movement | Flexible, allows controlled engine movement |

| Performance Application | Preferred for performance and racing | Preferred for comfort and daily driving |

| Cost | Generally lower | Generally higher |

Introduction: Solid Mount vs Rubber Mount

Solid mounts provide a direct connection between the engine and chassis, resulting in better power transfer and improved vehicle responsiveness. Rubber mounts use elastomeric material to absorb vibrations and noise, enhancing ride comfort and reducing drivetrain harshness. Choosing between solid and rubber mounts depends on balancing performance needs with comfort preferences.

Understanding Mounting Systems

Solid mount systems provide direct attachment between the engine or component and the chassis, maximizing power transfer and responsiveness by minimizing movement. Rubber mounts incorporate elastomeric material to absorb vibrations, reducing noise and improving comfort but allowing slight displacement under load. Understanding these mounting options helps you balance performance with ride smoothness depending on your vehicle's intended use.

What Is a Solid Mount?

A solid mount is a rigid engine or transmission mounting system designed to provide a direct connection between components, minimizing movement and enhancing performance. Unlike rubber mounts, which use elastomeric material to absorb vibrations and noise, solid mounts prioritize maximum power transfer and precision handling. This mounting type is commonly used in high-performance or racing vehicles where responsiveness and stability are critical.

What Is a Rubber Mount?

A rubber mount is a vibration isolator used to reduce noise and absorb shocks between two components by flexibly cushioning mechanical parts. It is made from durable elastomeric materials that provide elasticity, protecting your engine or machinery from harsh impacts and reducing wear. Compared to solid mounts, rubber mounts offer enhanced comfort and noise dampening but may sacrifice some rigidity and responsiveness.

Key Differences Between Solid and Rubber Mounts

Solid mounts provide direct, rigid connection between components, resulting in enhanced performance and precise control, especially in automotive and industrial applications. Rubber mounts, composed of flexible elastomeric material, excel at vibration isolation and noise reduction by absorbing shocks and minimizing transmission of mechanical vibrations. The key difference lies in trade-offs between durability and comfort: solid mounts prioritize stiffness and responsiveness, while rubber mounts emphasize cushioning and vibration dampening.

Performance Comparison: Solid vs Rubber Mount

Solid mounts provide superior performance by offering direct engine-to-chassis connection, minimizing engine movement and enhancing throttle response and handling precision in high-performance driving. Rubber mounts absorb vibrations and reduce noise, improving overall ride comfort but sacrificing some engine stability and sharpness in acceleration. Your choice depends on whether you prioritize performance and feedback or smoother, quieter operation during everyday driving.

Vibration and Noise Control

Solid mounts provide minimal vibration absorption, resulting in stronger noise transmission to the vehicle cabin, while rubber mounts excel at dampening vibrations and significantly reducing noise levels. Your choice impacts overall comfort, as rubber mounts isolate engine vibrations more effectively, enhancing the driving experience. For optimal vibration and noise control, rubber mounts are preferred in applications prioritizing quiet operation and smooth ride quality.

Durability and Maintenance Considerations

Solid mounts offer superior durability due to their rigid construction, providing long-lasting performance with minimal wear over time. Rubber mounts, while offering better vibration isolation, tend to degrade faster and require more frequent maintenance or replacement to maintain optimal function. Your choice depends on whether you prioritize longevity and structural stiffness or reduced noise and comfort.

Application Suitability: When to Choose Each Mount

Solid mounts provide maximum stiffness and direct power transfer, making them ideal for performance vehicles and racing applications where precision handling is critical. Rubber mounts excel in everyday driving or off-road scenarios by absorbing vibrations and reducing noise, enhancing comfort and extending component life. Your choice depends on whether you prioritize performance and responsiveness or comfort and noise isolation.

Conclusion: Making the Right Choice

Choosing between solid mount and rubber mount depends on balancing performance and comfort needs. Solid mounts provide superior engine stability and precise handling, ideal for high-performance driving, while rubber mounts offer enhanced vibration isolation and noise reduction, prioritizing ride comfort. Evaluating vehicle use and personal preferences ensures selecting the right mount for optimal driving experience.

solid mount vs rubber mount Infographic

libmatt.com

libmatt.com